Polyurethane elastomer forming method and sports safety protection article made by the method

A technology of safety protection and foaming polyurethane, which is applied in the field of polyurethane material forming, can solve the problems of human injury, cushioning, and rebound resilience, etc., and achieve the effect of enhancing protection, reducing surface viscosity, and increasing decorative functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

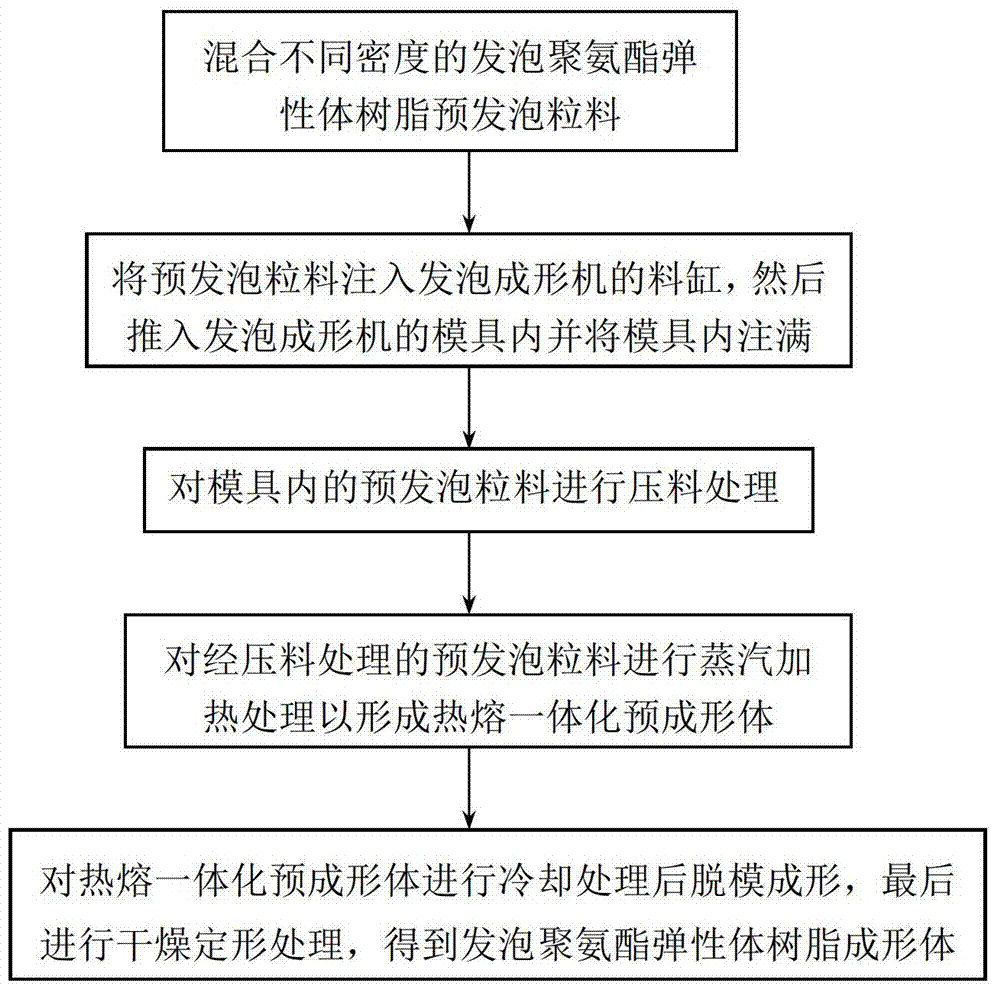

Method used

Image

Examples

Embodiment

[0053] According to the weight ratio of 1:1, pre-expanded polyurethane pellets (BASF) with densities of 110g / l and 120g / l were weighed respectively, and mixed with a mixer (manufactured by Shenzhen Huaweixin Machinery Equipment Co., Ltd.). 50 kg of the mixed polyurethane pre-expanded pellets were injected into the feed vat of a foam molding machine (K813 type, manufactured by Kurtz), and water was added to the feed vat at a rate of 30 ml / min. Push the pellets through the feeding pipe into the mold with a reserved pressing position in the foam molding machine. Due to the addition of an appropriate amount of water, the surface viscosity of the polyurethane pellets decreases, and the feeding process is smooth and there is no adhesion of the feeding pipe . After the pellets are filled with the mold, press material is carried out, and the material pressing distance is 15mm. Then open the steam valve of the forming machine, make the steam temperature reach 120°C, and the steam pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com