Method of extracting humic acid from peat

A humic acid and peat technology, applied in the direction of organic chemistry, can solve the problems of low purity of humate, unfavorable industrial production, long preparation time, etc., to shorten the extraction time, reduce the extraction cost, and improve the extraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

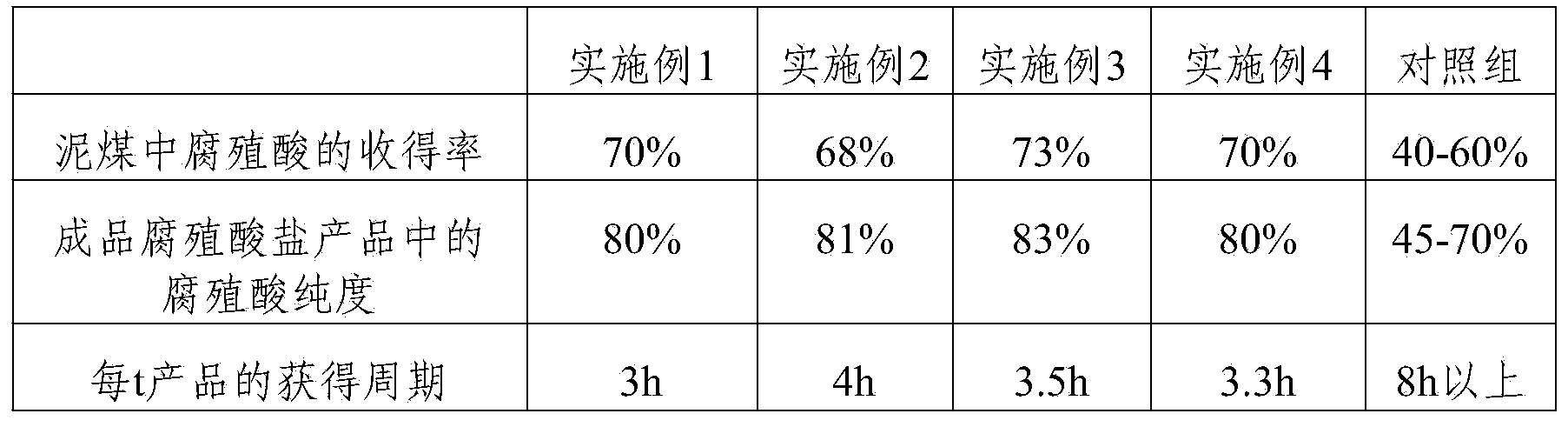

Examples

Embodiment 1

[0030] A method for extracting humic acid from peat, comprising the following steps:

[0031] (1) Peat pretreatment: After the peat is excavated, it is placed in the indoor natural environment, stored for 3 days, adjusted and detected for the ash and moisture of the peat, and set aside;

[0032] (2) Pulverization: the peat after step 1) is adjusted and detected, so that the ash of the peat is 20% and the moisture is 30%, then the peat is pulverized to 38 orders to obtain pulverized coal for use;

[0033] (3) Oxidation: Add the pulverized coal obtained in step 2) into the nitric acid solution with a concentration of 40%, wherein the ratio of pulverized coal to the nitric acid solution is 1:2, and the ratio unit is kg / l; adjust the temperature to 90°C , after 5 minutes of reaction, stand-by;

[0034] (4) Washing: wash the substance after the reaction in step 3) once with water to obtain a suspension for use;

[0035] (5) Filtration: the suspension obtained by washing in step 4...

Embodiment 2

[0044] On the basis of embodiment 1, other are all the same as embodiment 1, a kind of method extracting humic acid from peat, comprises the following steps:

[0045] (1) Peat pretreatment: After the peat is excavated, it is placed in the indoor natural environment, stored for 5 days, adjusted and detected for the ash and moisture of the peat, and set aside;

[0046] (2) Pulverization: the peat after step 1) is adjusted and detected, so that the ash content of the peat is 19% and the moisture is 25%, then the peat is pulverized to 42 orders to obtain pulverized coal for use;

[0047] (3) Oxidation: Add the pulverized coal obtained in step 2) into the nitric acid solution with a concentration of 45%, wherein the ratio of pulverized coal to the nitric acid solution is 2:3, and the ratio unit is kg / l; adjust the temperature to 95°C , after 8 minutes of reaction, set aside;

[0048] (4) Washing: the substance after the reaction in step 3) is washed twice with water to obtain a su...

Embodiment 3

[0056] On the basis of embodiment 1, other steps are with embodiment 1, a kind of method for extracting humic acid from peat, comprises the following steps:

[0057] (1) Peat pretreatment: After the peat is excavated, it is placed in the indoor natural environment, stored for 4 days, the ash and moisture of the peat are adjusted and tested, and it is ready for use;

[0058] (2) Pulverization: the peat after step 1) is adjusted and detected, so that the ash content of the peat is 15% and the moisture is 20%, then the peat is pulverized to 40 orders to obtain pulverized coal for use;

[0059] (3) Oxidation: Add the pulverized coal obtained in step 2) into the nitric acid solution with a concentration of 43%, wherein the ratio of pulverized coal to the nitric acid solution is 3:5, and the ratio unit is kg / l; adjust the temperature to 93°C , after 7 minutes of reaction, set aside;

[0060] (4) Washing: wash the substance after the reaction in step 3) once with water to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com