Graphite EPS bead and production technology thereof

A production process and bead technology, which is applied in the field of graphite EPS beads and its production process, can solve the problems of long production cycle, lower product quality and raw material utilization rate, and increase production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

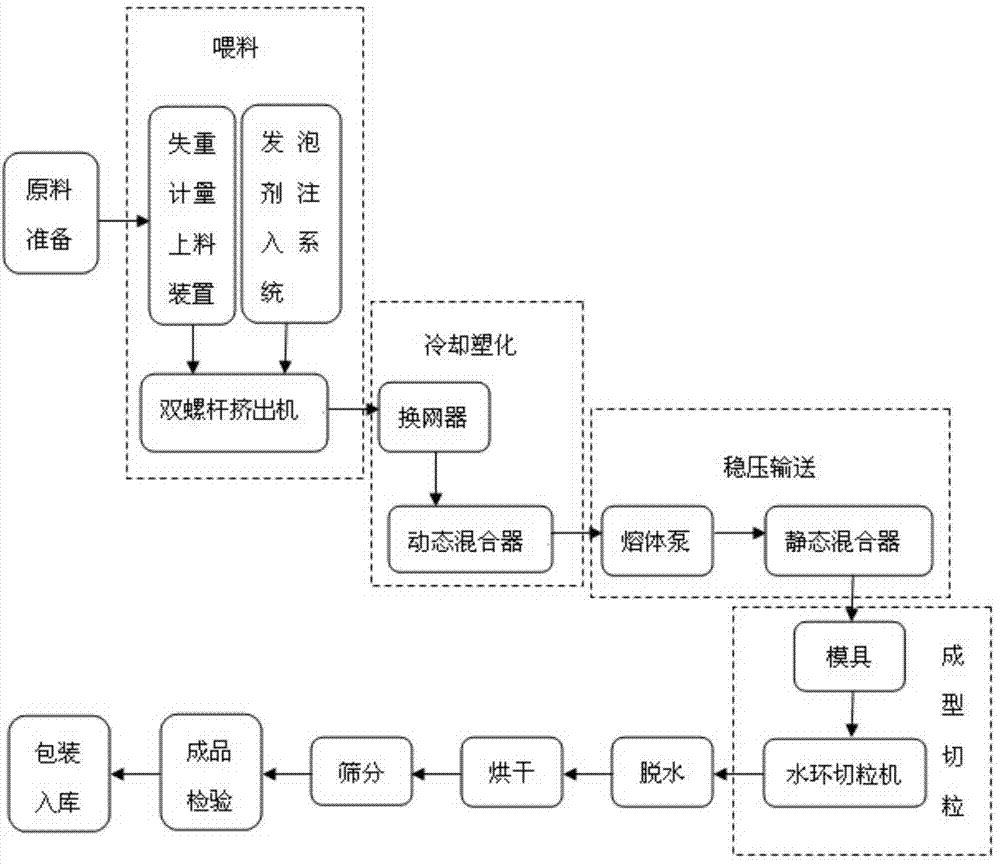

Method used

Image

Examples

Embodiment 1

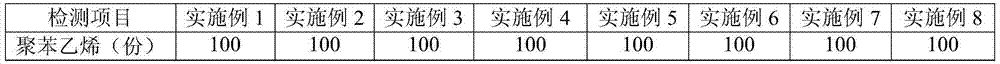

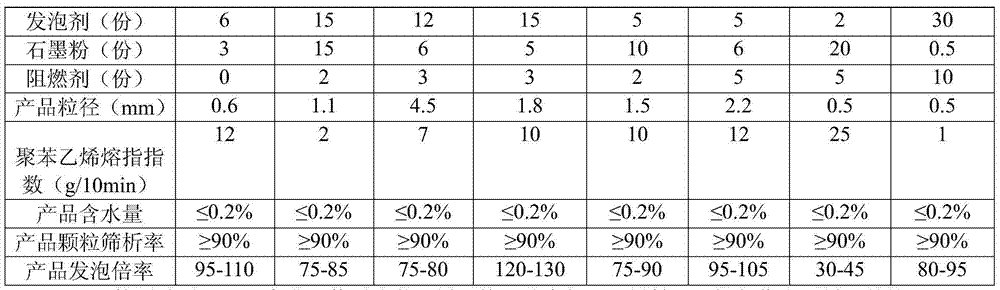

[0029] 1) Material preparation: According to technical requirements, weigh 100 parts of polystyrene particles with a melting index of 12g / 10min, 6 parts of pentane, and 3 parts of surface-modified 200-mesh flake graphite powder;

[0030] 2) Feeding: Heat the co-rotating twin-screw extruder and keep it between 190 and 200°C, then put polystyrene particles, surface-modified graphite powder and flame retardant into the co-rotating twin-screw extruder through the metering device In the extruder, when the raw materials put into the co-rotating twin-screw extruder are melted and melted to a certain viscosity, the prepared foaming agent is injected into the middle section of the co-rotating twin-screw extruder, and then extruded through the co-rotating twin-screw extruder The shearing effect of the machine makes the components and materials mixed and homogenized;

[0031] 3) Cooling and plasticizing: Extrude the mixed melt into a hydraulic screen changer to filter, then inject the me...

Embodiment 2

[0039] 1) Material preparation: According to technical requirements, weigh 100 parts of polystyrene particles with a melting index of 2g / 10min, 15 parts of dichloromethane, 15 parts of surface-modified 600-mesh expandable graphite powder and 2 parts of hexabromocyclododecane share;

[0040] 2) Feeding: Heat the co-rotating twin-screw extruder and keep it between 190 and 200°C, then put polystyrene particles, surface-modified graphite powder and flame retardant into the co-rotating twin-screw extruder through the metering device In the extruder, when the raw materials put into the co-rotating twin-screw extruder are melted and melted to a certain viscosity, the prepared foaming agent is injected into the middle section of the co-rotating twin-screw extruder, and then extruded through the co-rotating twin-screw extruder The shearing effect of the machine makes the components and materials mixed and homogenized;

[0041] 3) Cooling and plasticizing: Extrude the mixed melt into a...

Embodiment 3

[0049] 1) Material preparation: according to technical requirements, weigh 100 parts of polystyrene particles with a melting index of 7g / 10min, 12 parts of R152a, 6 parts of surface-modified 400-mesh expanded graphite powder and 3 parts of hexabromocyclododecane;

[0050] 2) Feeding: Heat the co-rotating twin-screw extruder and keep it between 190 and 200°C, then put polystyrene particles, surface-modified graphite powder and flame retardant into the co-rotating twin-screw extruder through the metering device In the extruder, when the raw materials put into the co-rotating twin-screw extruder are melted and melted to a certain viscosity, the prepared foaming agent is injected into the middle section of the co-rotating twin-screw extruder, and then extruded through the co-rotating twin-screw extruder The shearing effect of the machine makes the components and materials mixed and homogenized;

[0051] 3) Cooling and plasticizing: Extrude the mixed melt into a hydraulic screen ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com