Fume-elimination/dust-removal car at furnace top

A technology for smoke and dust removal and bag filter, which is used in coke ovens, petroleum industry, combined devices, etc., can solve the problems of long cycle, high temperature, and many pollutants, and achieves low production cost, simple structure and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

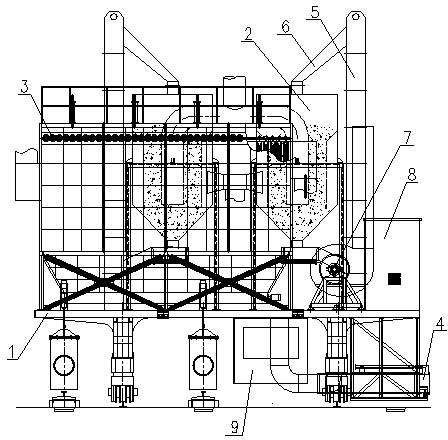

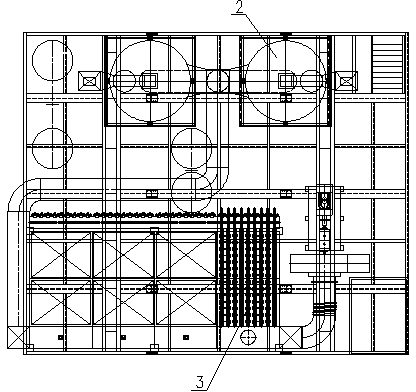

[0011] A furnace top smoke elimination and dust removal vehicle, comprising a walking vehicle 1, a coke particle adsorption device 2, a bag dust collector 3 and a side suction pipe device 4, the coke particle adsorption device 2 is installed on the rear side of the upper end of the walking vehicle 1, and the bag dust collector 3 is installed on the front side of the upper end of the trolley 1 and is connected to the air outlet of the coke particle adsorption device 2 through a conduit. A bucket elevator 5 is installed on the side of the coke particle adsorption device 2 and is installed on the trolley 1. The upper end of the bucket elevator 5 passes through The feed pipe 6 is connected to the top of the coke particle adsorption device 2, the lower end of the bucket elevator 5 is connected to the bottom of the coke particle adsorption device 2 through the feeding pipe, and the top of the trolley 1 is also equipped with a fan unit 7 connected to the coke particle adsorption device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com