Biomass fuel and granule-forming manufacture method thereof

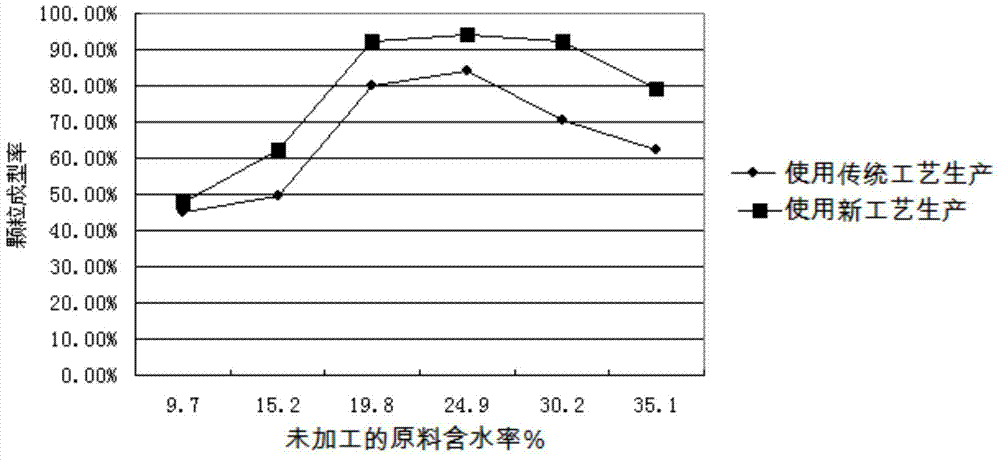

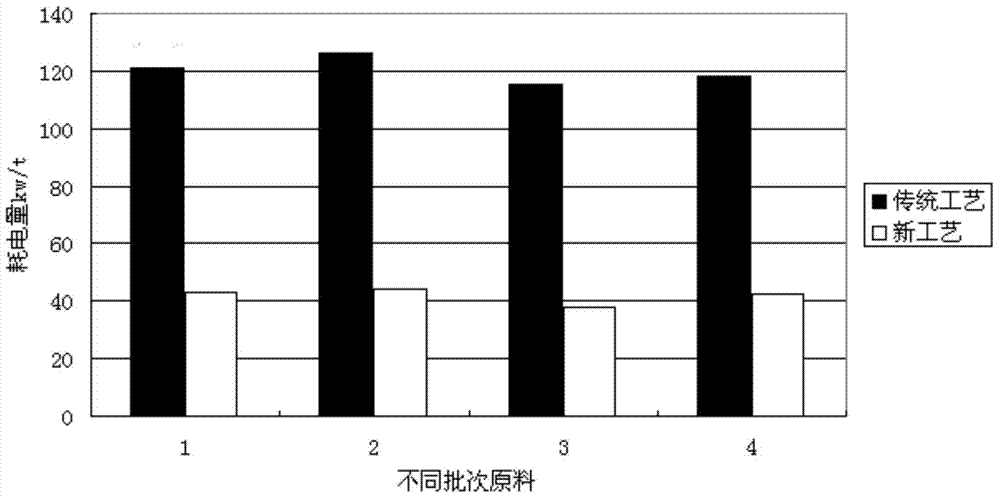

A biomass fuel and biomass material technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of very high water content, long time consumption, and long time consumption, so as to save time and energy consumption , suppression of energy consumption reduction, the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take 60 kg of corn stalks with a water content of 20%, and grind them into 20-mesh granules. After crushing 26 kg of bamboo with a water content of 6% into 40 meshes, add them to the corn stalk granules, and stir for 4 minutes. The resulting mixture was put into a compression granulator model MZLH508JG to produce granules with a diameter of 0.8 cm.

Embodiment 2

[0029] Take 70 kg of wheat straw with a water content of 25%, crush it into 30-mesh particles, and pass the obtained straw particles through a cyclone dust collector with a rotating speed of 100 r / min. After 30kg of bamboo with a moisture content of 6% was crushed into 70 meshes, it was added to the dedusted wheat straw particles and stirred for 5 minutes. The resulting mixture was put into a compression granulator model MZLH508JG to produce granules with a diameter of 0.8 cm.

Embodiment 3

[0031] Get the sawdust 80kg that moisture content is 30%, be ground into 40 order particles, after the bamboo that 34kg moisture content is 6% is ground into 100 orders, join in the sawdust granule, stir 6 minutes. The resulting mixture was put into a compression granulator model MZLH508JG to produce granules with a diameter of 0.8 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com