Technology for precisely controlling thickness of quenching layer of automobile wheel-shaft piston cover cap

A technology of precise control and quenching layer, applied in the field of quenching process, can solve the problem of hardened layer that cannot meet the requirements of holes, and achieve the effect of easy automation, good working conditions and high heat treatment quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

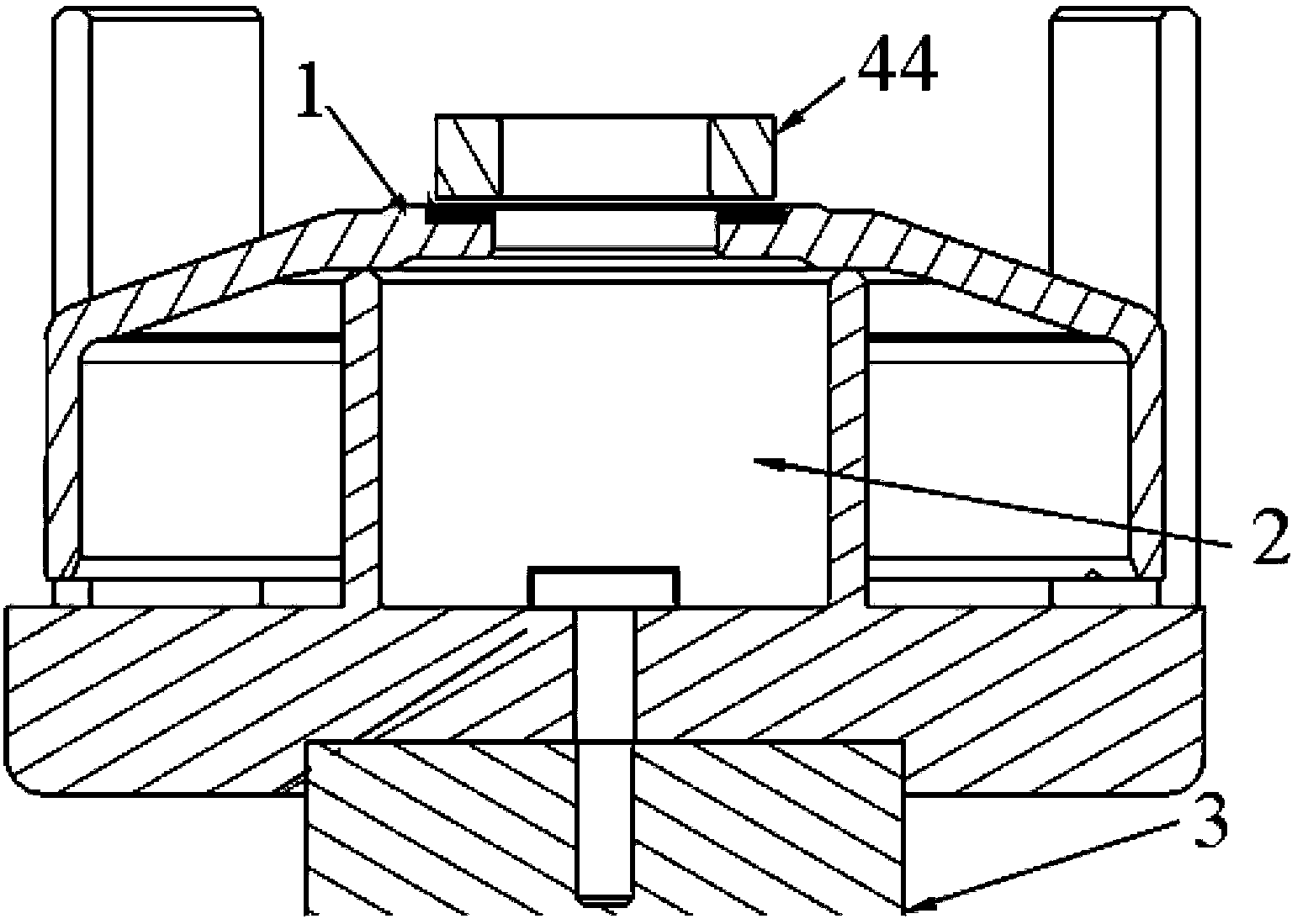

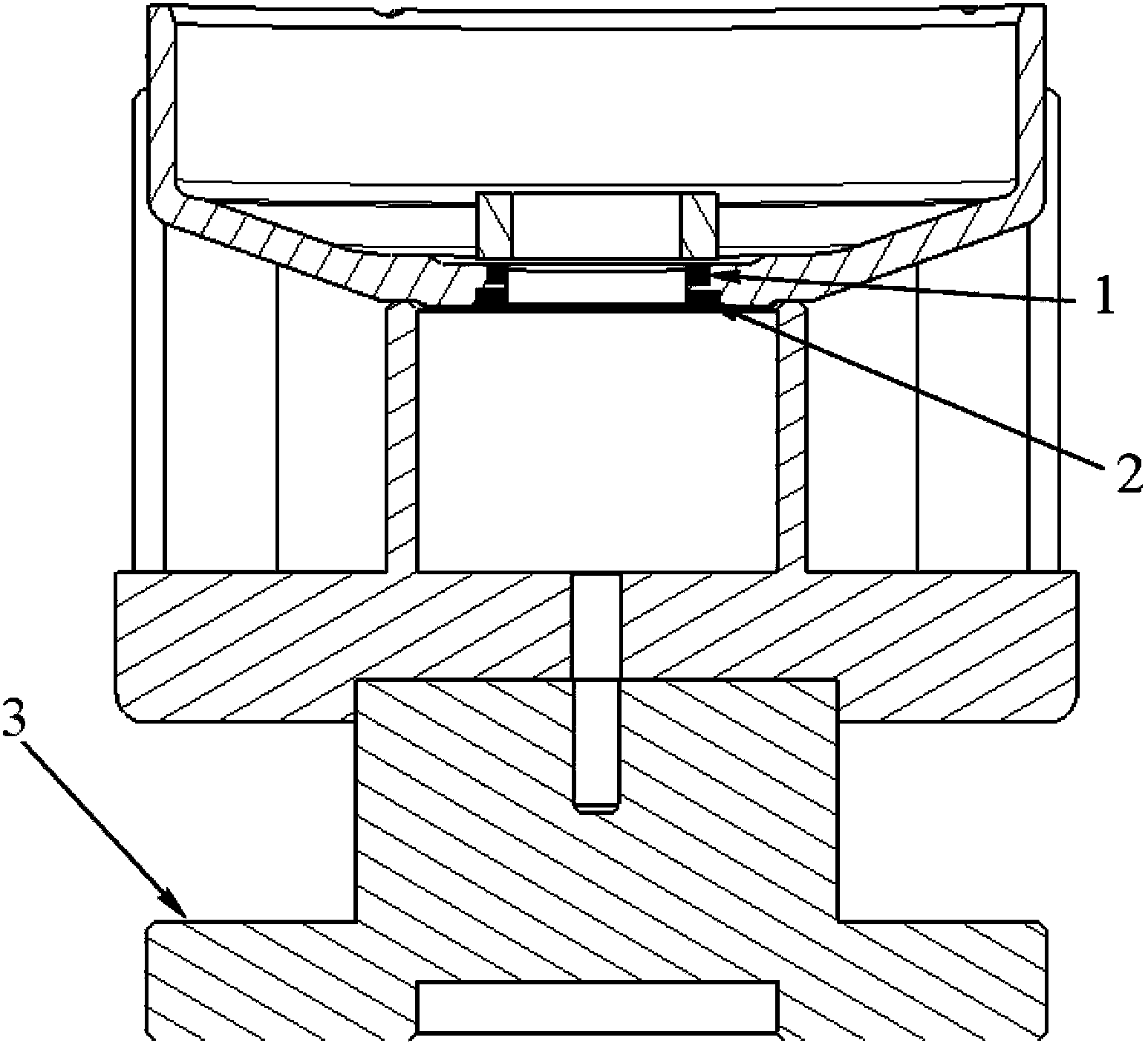

[0026] The process of precisely controlling the thickness of the quenched layer of the piston cover of the automobile wheel axle, the assembly diagram is as follows Figure 1-2 shown, including the following steps:

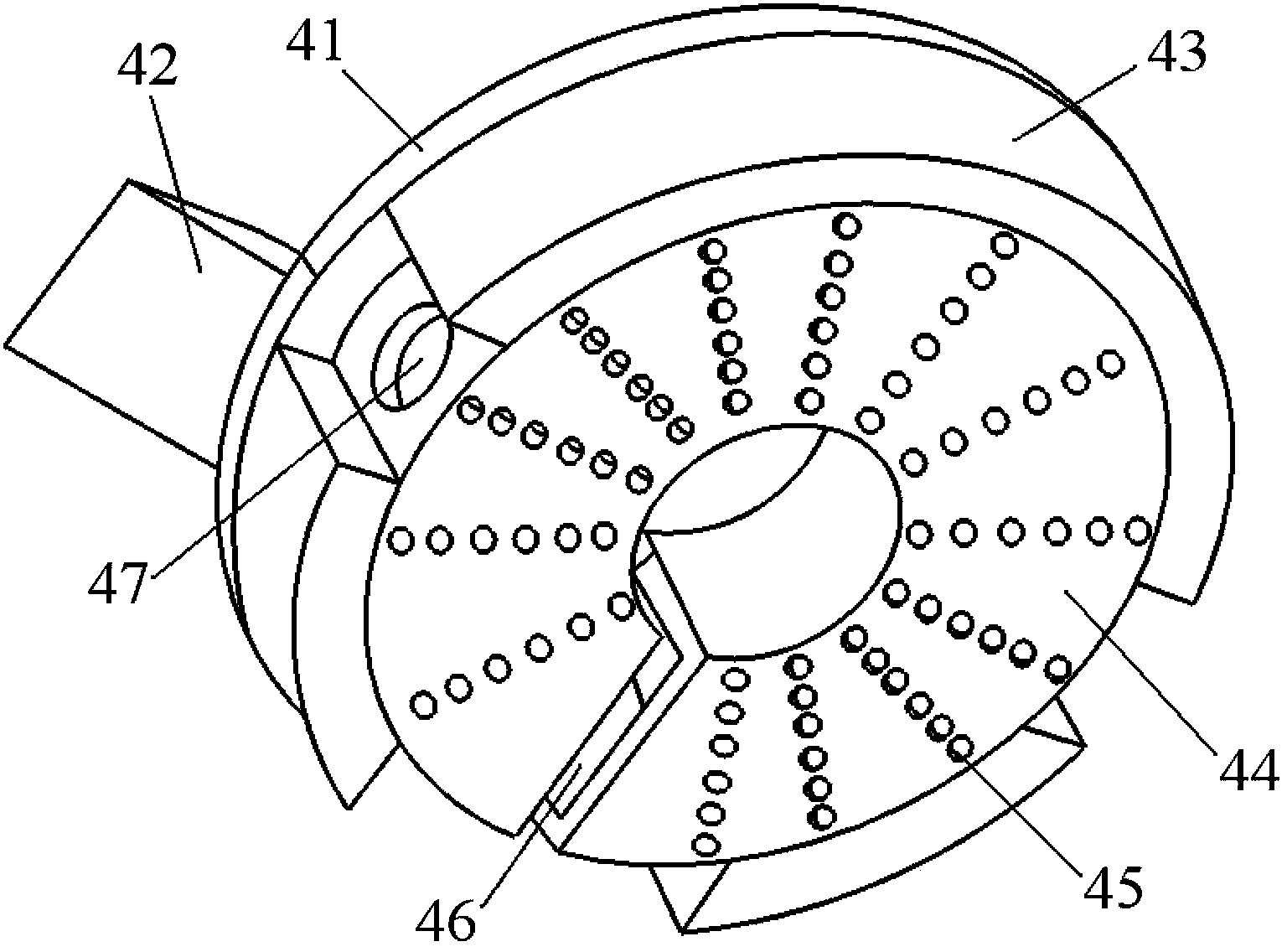

[0027] (1) Fix the position of the automobile axle piston cover 1 by using the clamp composed of the chuck 2 and the base 3, put the large-diameter inductor effective coil 44 on the upper end of the inner hole of the automobile axle piston cover 1, and The upper end surface of the hole is quenched to form a hardened layer with a depth of 1-2mm;

[0028] (2) turn over the automobile wheel shaft piston cover 1, select the effective coil 44 of the inductor matching the outer surface diameter of the automobile wheel shaft piston cover 1 to quench the other end face of the hole, and quench the liquid in the base 3. The quenched side in step (1) is immersed in the quenching liquid, so that the heat of the effective coil of the inductor will not affect the hardened laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com