Construction method for preventing deformation of underground comprehensive pipe gallery in high water level liquefaction area

A technology of integrated pipe gallery and construction method, applied in water conservancy projects, underwater structures, excavation, etc., to achieve the effect of preventing floating deformation, simple construction process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

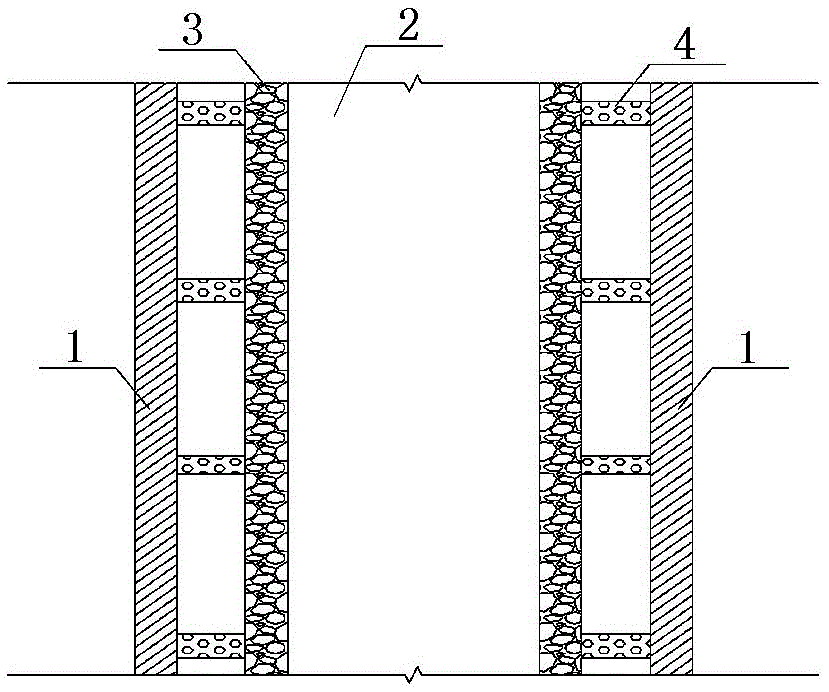

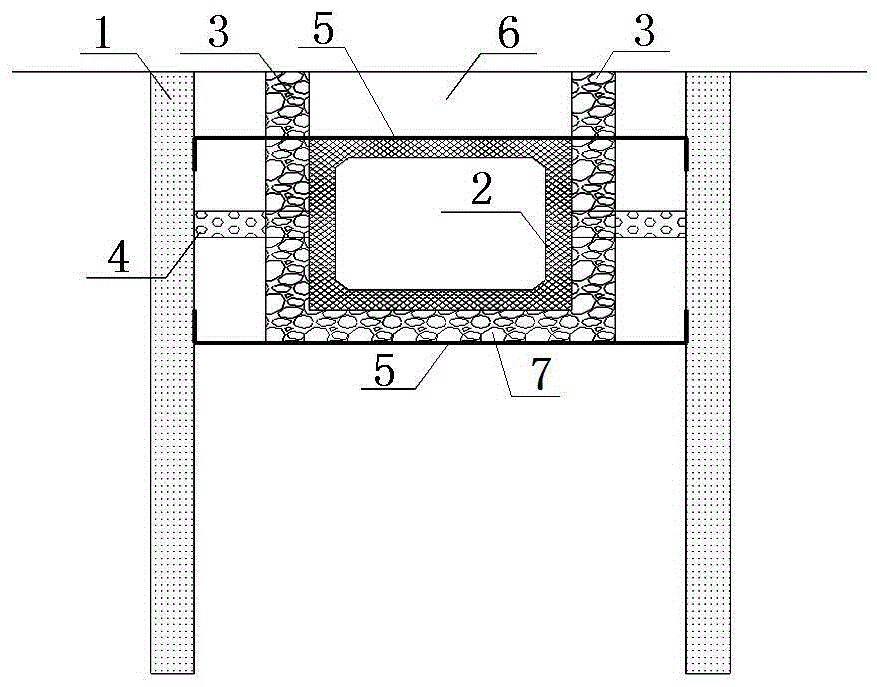

[0026] Example: such as Figure 1-5 As shown, this embodiment specifically relates to a construction method for preventing deformation of an underground comprehensive pipe gallery in a high water level liquefaction area, and the construction steps are as follows:

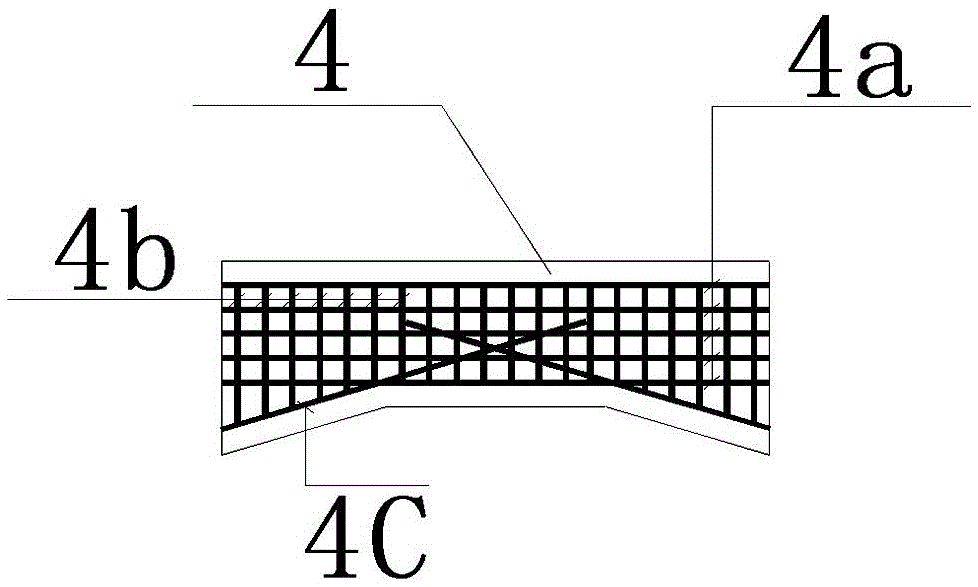

[0027] (1) Build enclosure 1 on both sides of the foundation pit to be excavated. The form of enclosure 1 can be reinforced concrete sheet pile, steel sheet pile, or underground diaphragm wall. The outer edge line is not less than 800mm to meet the construction operation space between the enclosure 1 and the underground comprehensive pipe gallery 2, and the depth of the enclosure 1 drilled into the soil is greater than the buried depth of the underground comprehensive pipe gallery 2 in the foundation pit; Pre-embed steel bars or steel plate connectors at the position where the shear connection key 4 needs to be connected. If the structural form of the enclosure 1 is reinforced concrete sheet piles, and the undergrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com