A tower type linear pumping unit

A pumping unit, straight line technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large vibration of the whole machine, complex mechanical reversing system, easy damage of guide wheel bearings, etc., and achieve power The effect of less, smooth and flexible movement, and smooth operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Describe the present invention below in conjunction with specific embodiment:

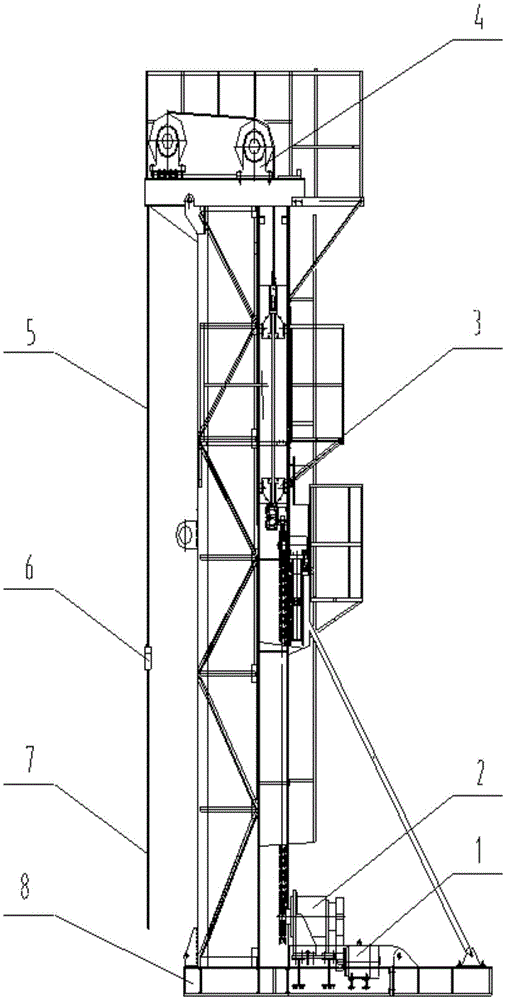

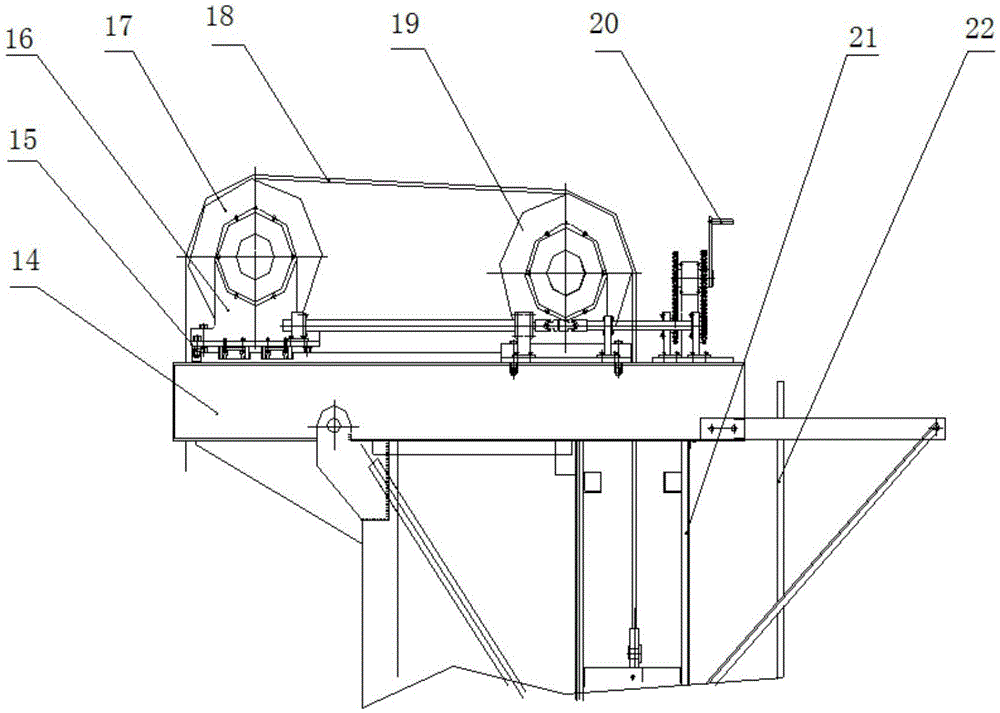

[0031] Refer to attached figure 1 And attached figure 2 , The tower-type linear pumping unit in this embodiment includes a base 8 and a tower 21, a driving mechanism, a transmission mechanism, a workover displacement device 4, and an oil well polished rod 7.

[0032] The base 8 is positioned at the lowermost end of the complete machine and directly contacts the ground. The drive mechanism is composed of a motor 1 and a reducer 2. The drive mechanism is fixed on the base with bolts. The output end of the motor 1 is connected to the input end of the reducer 2 through a transmission belt. The motor 1 is on the right side of the reducer 2. The output end of the speed reducer 2 is connected with the drive sprocket 13 of the transmission mechanism.

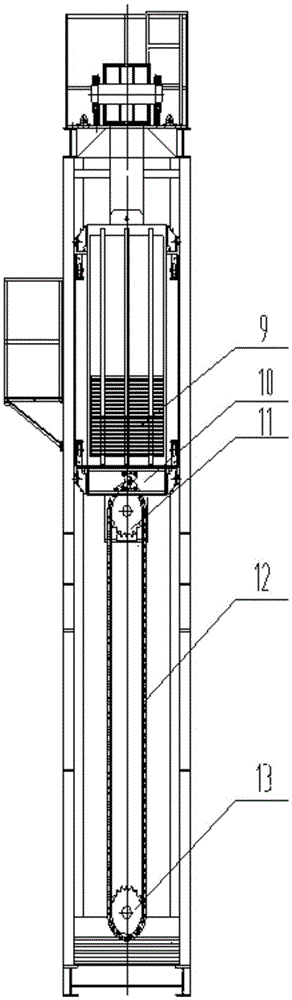

[0033] Transmission mechanism comprises driving sprocket 13, driven sprocket 11, chain 12, bell crank 3, reciprocating frame 10, counterweight bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com