A cascaded phase change heat storage and heat release integrated device using metal foam

A metal foam, phase-change heat storage technology, which is applied to heat storage equipment, heat exchange equipment, heat exchanger types, etc. Heat transfer ability, the effect of improving the heat storage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

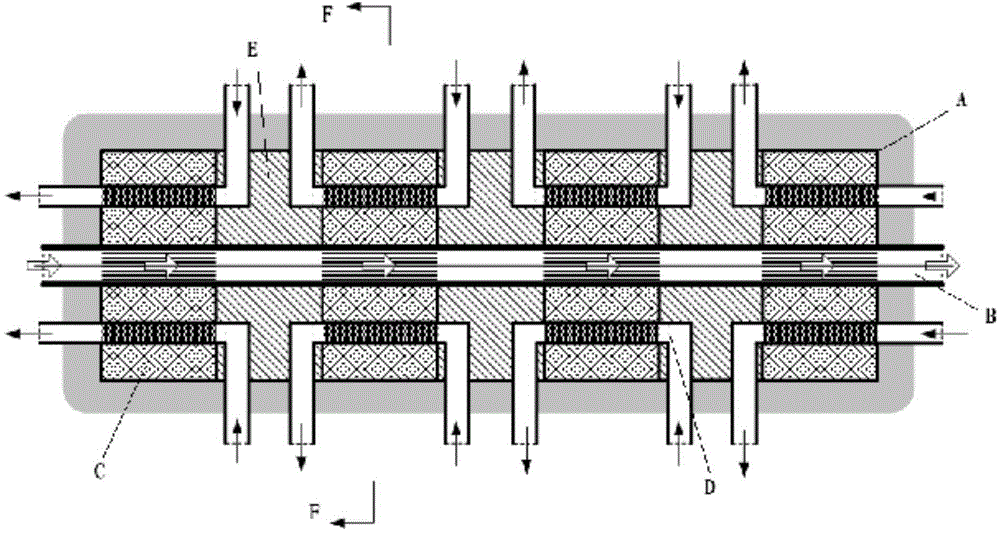

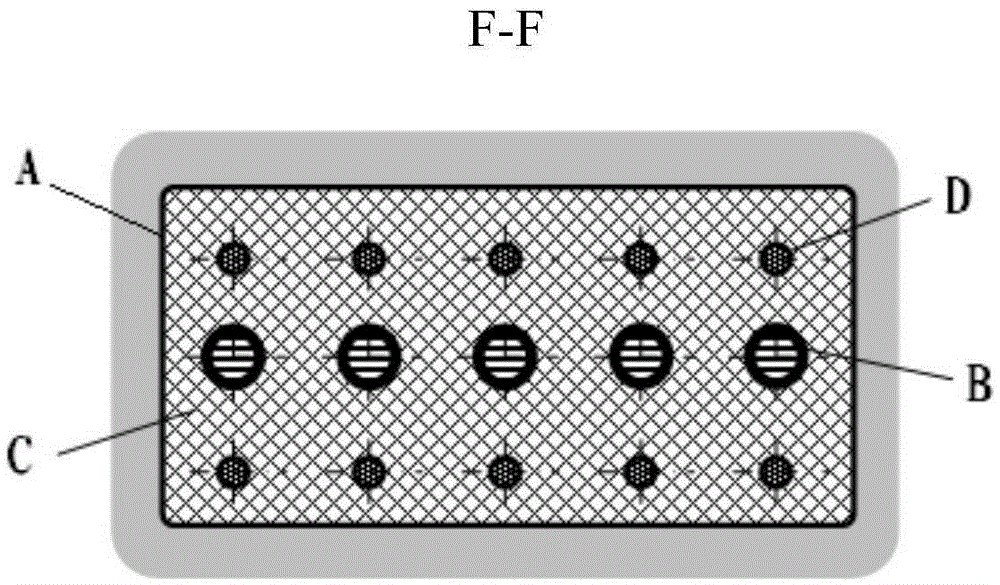

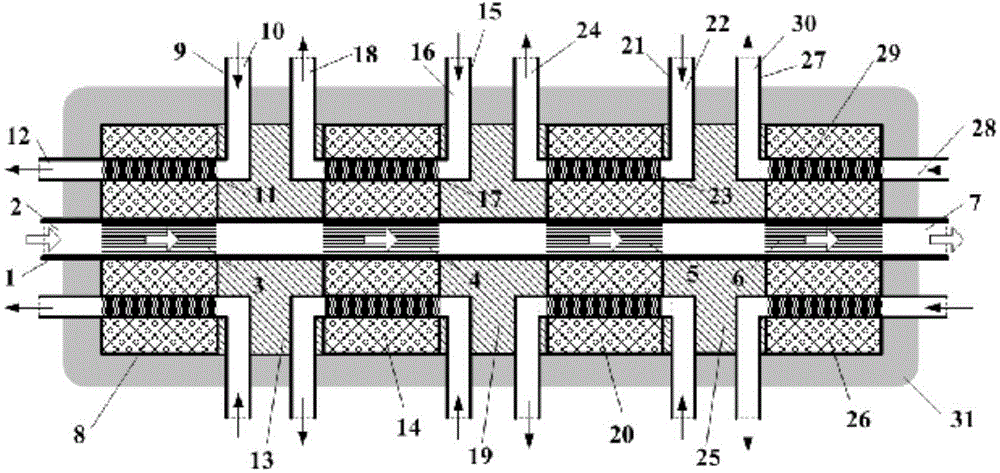

[0027] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate, a cascaded phase change heat storage and heat release integrated device using metal foam in this embodiment includes a shell A, a heat release pipe part B, a four-stage phase change material heat storage unit C, and a four-stage heat absorption pipe part D, three compartments E;

[0028] Wherein, the four-stage phase-change material thermal storage unit C includes a primary thermal storage unit 8, a secondary thermal storage unit 14, a third-stage thermal storage unit 20, and a fourth-stage thermal storage unit 26;

[0029] The four-stage heat-absorbing pipe part D includes a first-stage heat-absorbing pipe part, a second-stage heat-absorbing pipe part, a third-stage heat-absorbing pipe part, and a fourth-stage heat-absorbing pipe part;

[0030] Heat release pipe part B includes heat release pipe 1, heat release pipe inlet 2, heat release pipe metal foam I3, heat release pipe metal foam II4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com