Dynamic weight measuring method for steel ball mill

A technology of weight measurement and steel ball milling, which is applied in the direction of measuring devices, weighing, and weighing equipment using fluid balance, etc., can solve the problems of steel ball mill dynamic weight measurement, etc., achieve simple methods, improve milling efficiency, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

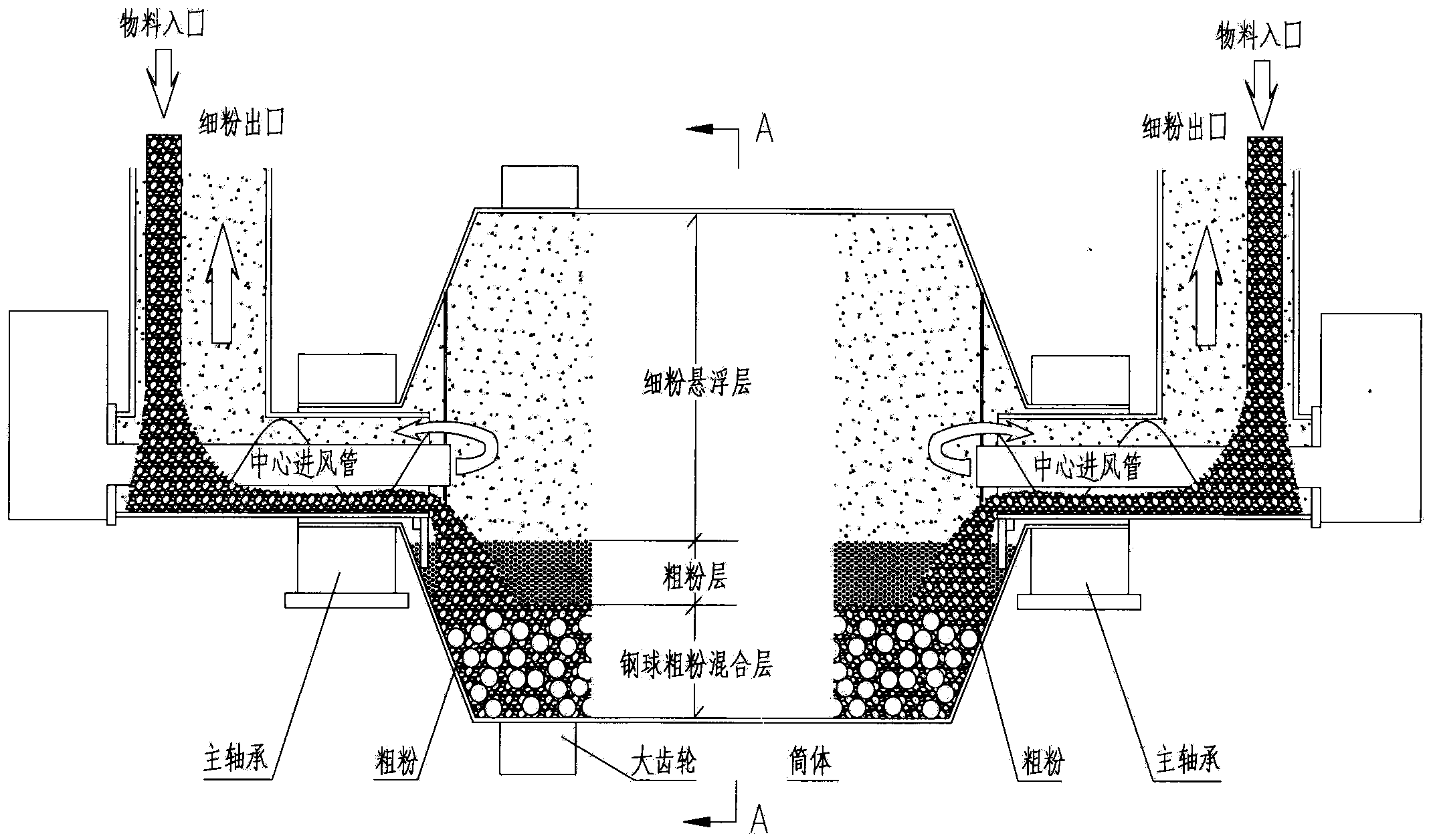

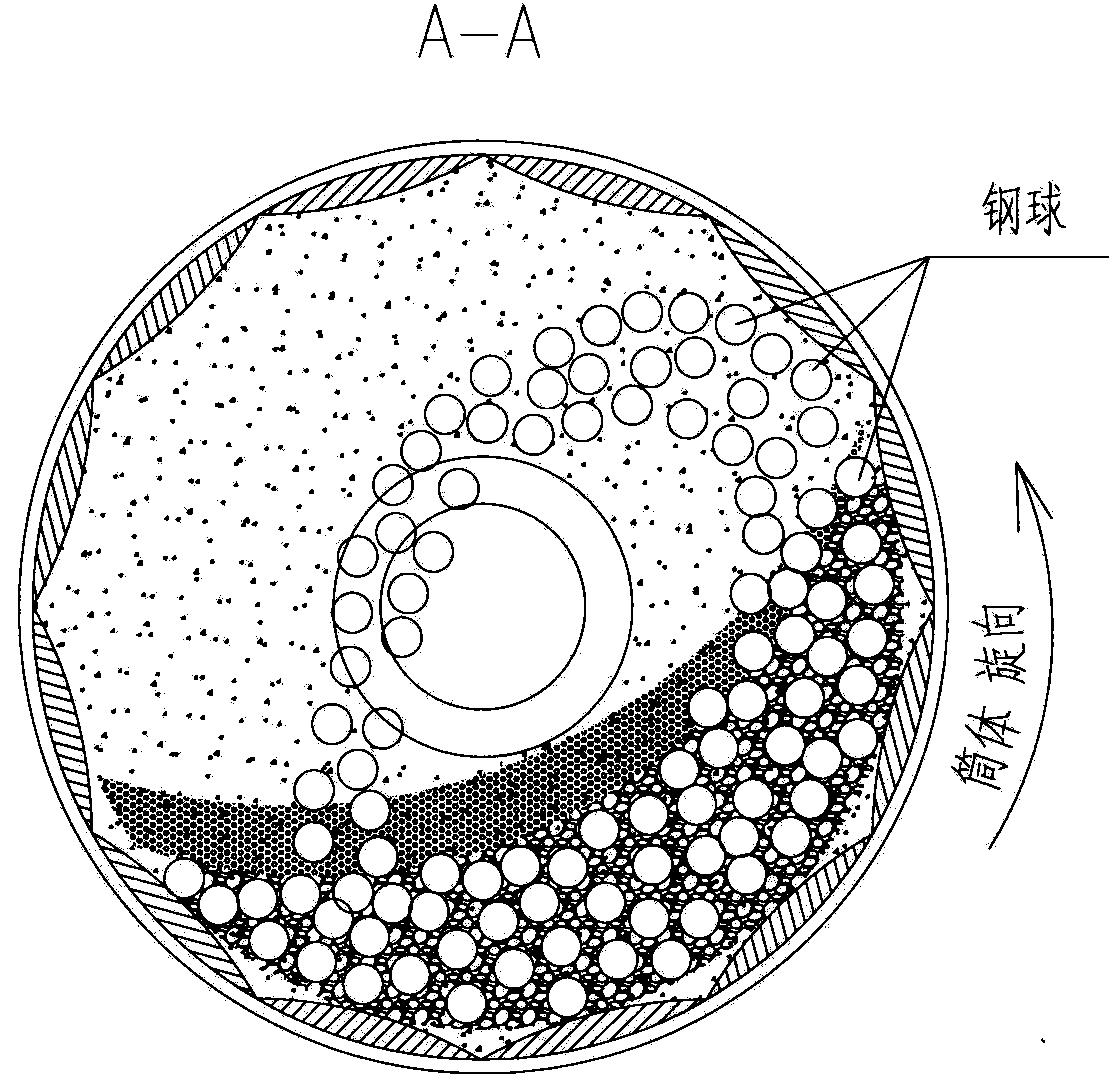

[0019] 1. Establishment of the basic model

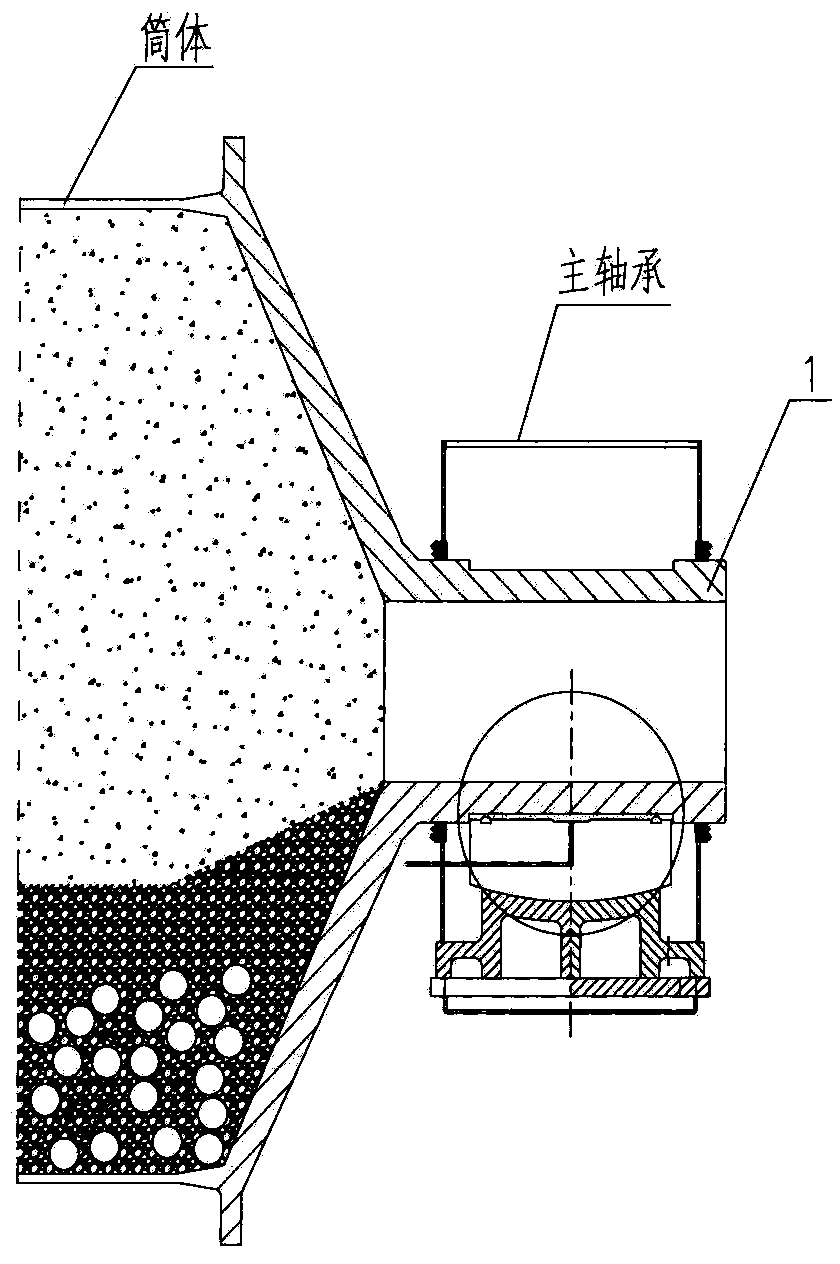

[0020] The present invention requires that the main bearing of the steel ball mill adopts a hydrostatic bearing. combine image 3 , Figure 4 , the hydrostatic bearing can use high-pressure lubricating oil to hold up the entire rotating part of the mill. When the high-pressure oil is injected into the middle of the bearing bush 3, a top grinding high-pressure oil layer 4 is formed on the contact surface between the hollow shaft 1 and the bearing bush 3 of the mill, and the entire rotating part of the mill Suspended above the oil layer. There is a high-pressure sealing ring 2 protruding from the circumference of the contact surface between the bearing bush 3 and the mill hollow shaft 1, so that the oil drain gap is fixed and uniform, and the top grinding area is fixed. This way we ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com