Detachable in-situ heat treatment device and using method thereof

A heat treatment device and in-situ technology, applied in the preparation of test samples, etc., can solve the problems of no online monitoring, waste of equipment resources, and inability to obtain online, and achieve convenient operation, reduced equipment costs, and flexible and convenient connection methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

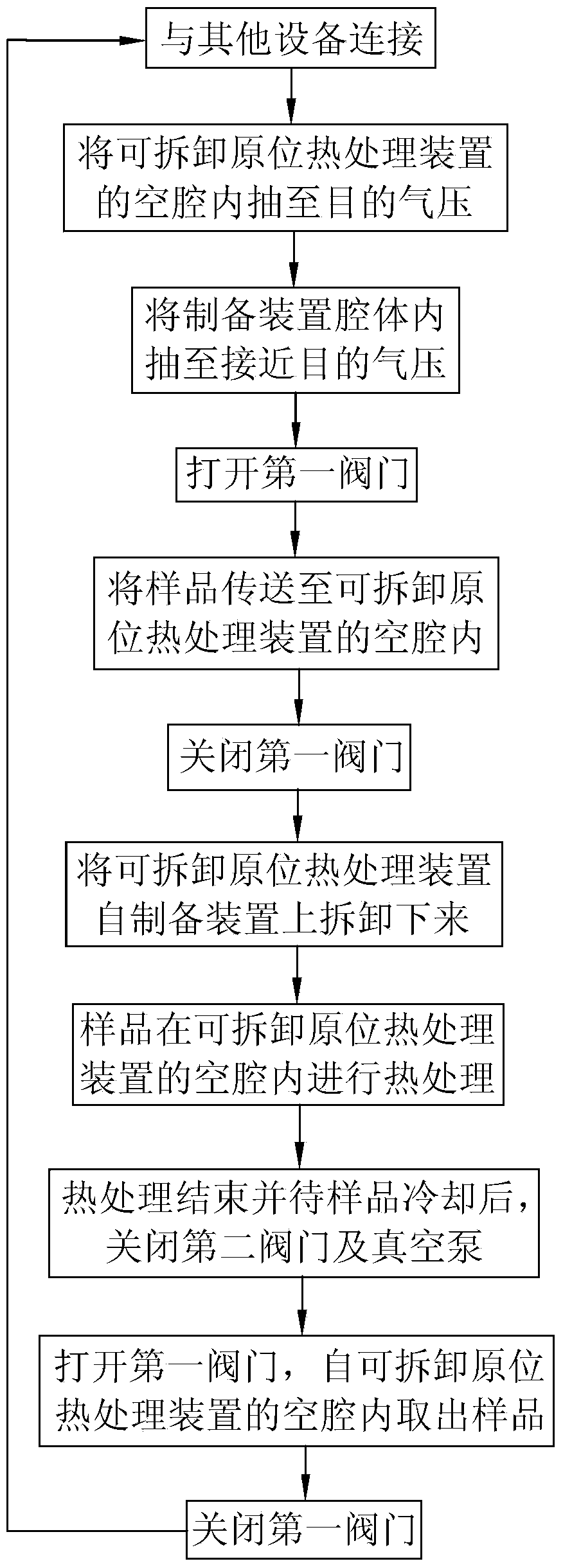

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

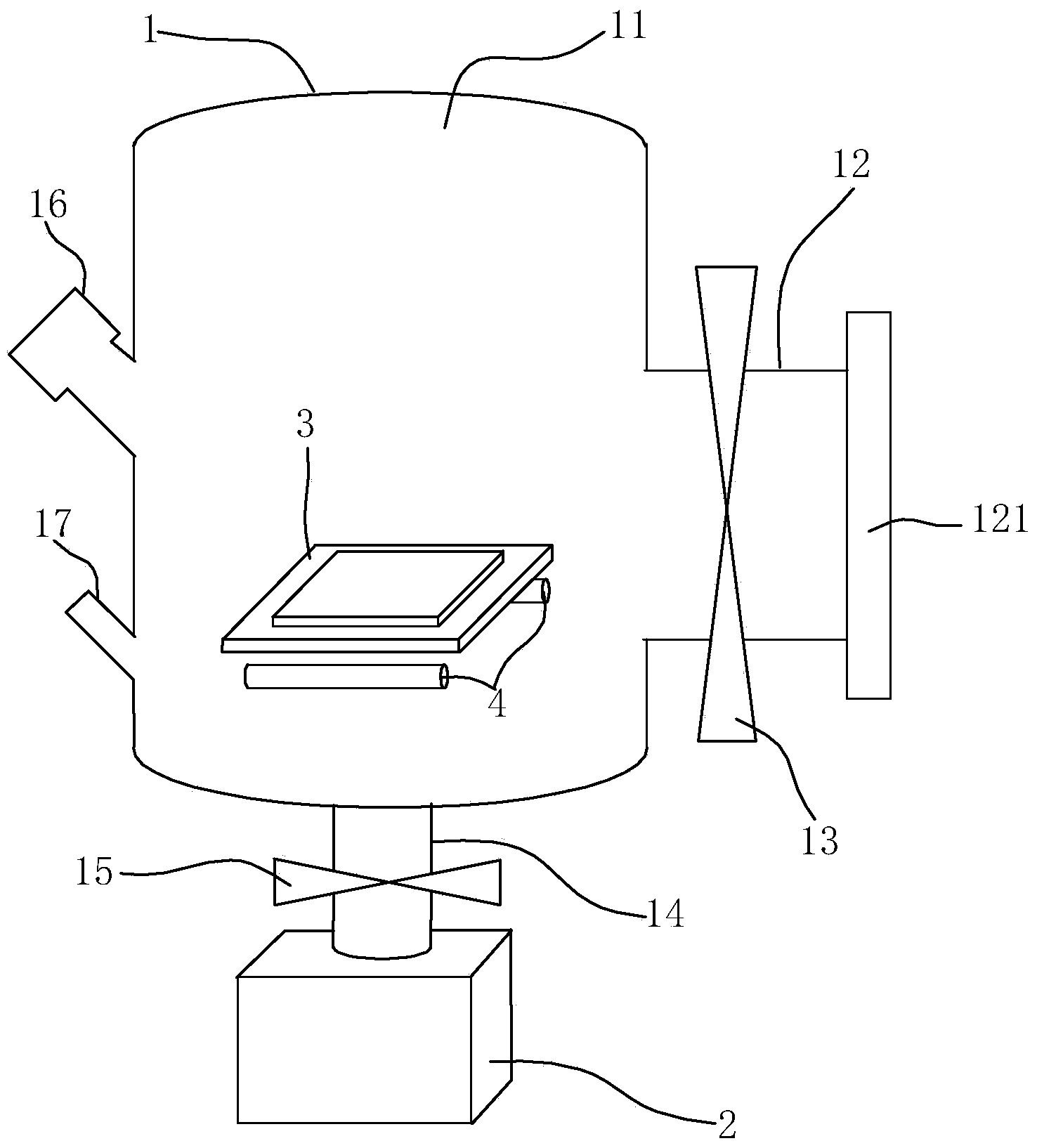

[0032] Such as figure 1 As shown, a detachable in-situ heat treatment device in this embodiment includes a heating body 1 capable of heating. The heating body 1 has a cavity 11 for placing samples. For the convenience of placing samples, a There is a support 3 for placing the sample and a heater 4 for heating. The heater 4 in this embodiment is arranged under the support 3. The heater 4 is used for heat treatment of the sample, and the heating in the cavity 11 The temperature is controlled according to the processing requirements.

[0033] The heating body 1 is provided with a first docking joint 12 that communicates with the cavity 11. The first docking joint 12 has a quick connection interface 121 that can be detachably connected to other equipment. A first valve 13 for blocking and opening the communication with the cavity 11 is provided....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com