Method for detecting disulfide bond breakage of protein

A protein and disulfide bond technology, applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

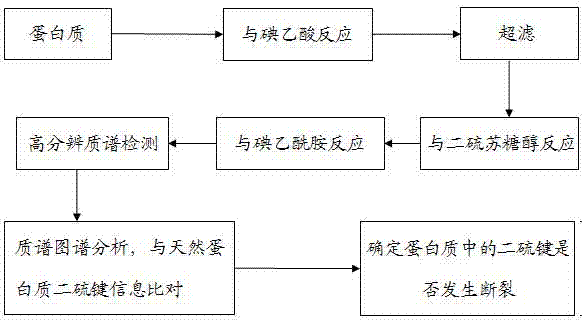

Image

Examples

Embodiment 1

[0033] 1. The free thiol group of protein reacts with iodoacetic acid

[0034] (1) Preparation of protein solution: dissolve with 50mM ammonium bicarbonate solution to obtain 1.0 mg / ml protein solution;

[0035] (2) Preparation of iodoacetic acid solution: prepare 100mM iodoacetic acid solution with ultrapure water;

[0036] (3) Reaction of protein free sulfhydryl groups with iodoacetic acid: Mix 10 μl of protein solution with 3 μl of iodoacetic acid solution, and after mixing, place in the dark for 30 minutes;

[0037] (4) Remove iodoacetic acid that did not participate in the reaction: use a 3000Da ultrafiltration centrifuge tube to remove the excess iodoacetic acid that did not participate in the reaction.

[0038] 2. Dithiothreitol breaks protein disulfide bonds

[0039] (1) Preparation of dithiothreitol solution: prepare 100mM dithiothreitol solution with ultrapure water;

[0040] (2) Dithiothreitol cleavage of protein disulfide bonds: add 2 μl of dithiothreitol soluti...

Embodiment 2

[0056] 1. The free thiol group of protein reacts with iodoacetic acid

[0057] (1) Preparation of protein solution: dissolve with 100mM ammonium bicarbonate solution to obtain 1.0 mg / ml protein solution;

[0058] (2) Preparation of iodoacetic acid solution: prepare 100mM iodoacetic acid solution with ultrapure water;

[0059] (3) Reaction of protein free sulfhydryl groups with iodoacetic acid: Mix 20 μl of protein solution with 3 μl of iodoacetic acid solution, and after mixing, place in the dark for 30 minutes;

[0060] (4) Remove iodoacetic acid that did not participate in the reaction: use a 2000Da ultrafiltration centrifuge tube to remove excess iodoacetic acid that did not participate in the reaction.

[0061] 2. Dithiothreitol breaks protein disulfide bonds

[0062] (1) Preparation of dithiothreitol solution: prepare 100mM dithiothreitol solution with ultrapure water;

[0063] (2) Dithiothreitol cleavage of protein disulfide bonds: add 2 μl of dithiothreitol solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com