Test method, test fixture and test device for thin core board layer short risks

A technology of testing device and testing method, which is applied in the direction of measuring device shell, testing dielectric strength, etc., can solve the problems of wasting plates, small thickness of interlayer medium, and low economic benefit, so as to save work efficiency, avoid contact short circuit, and ensure safety high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below:

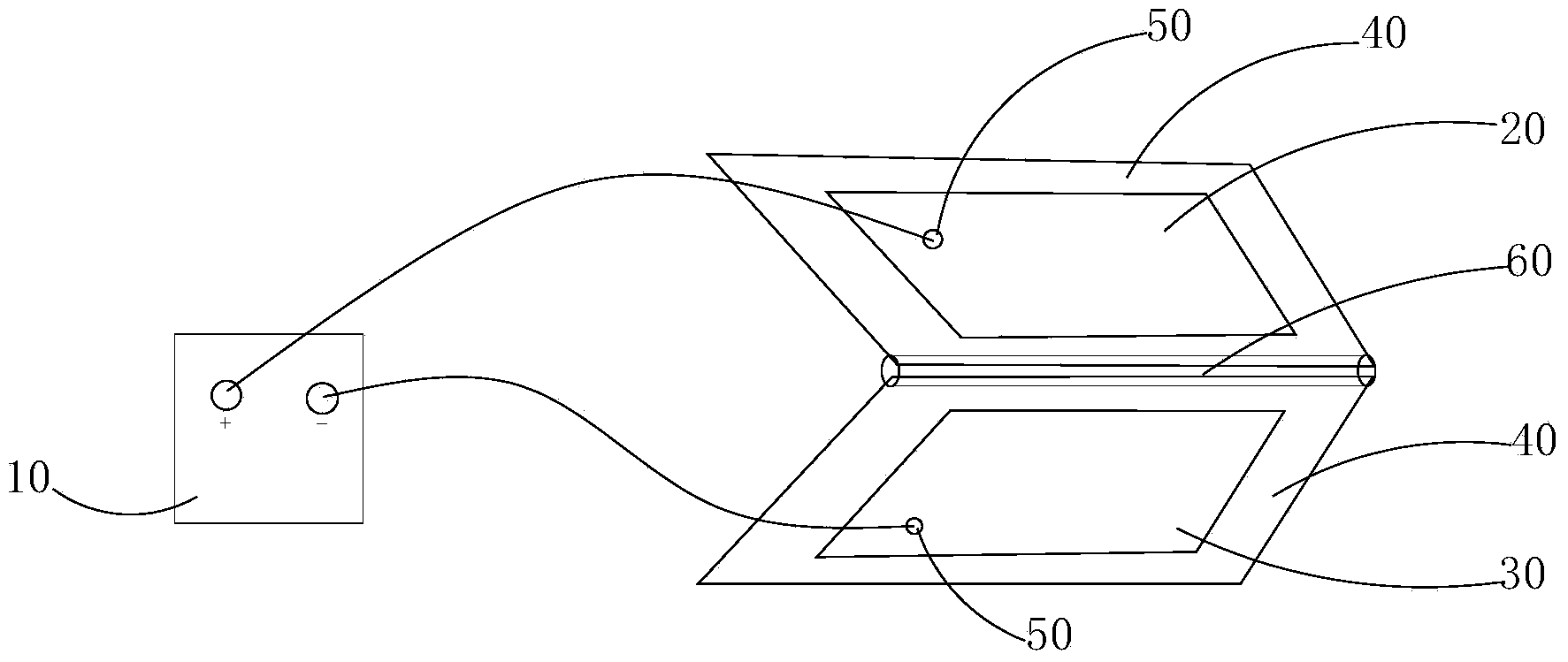

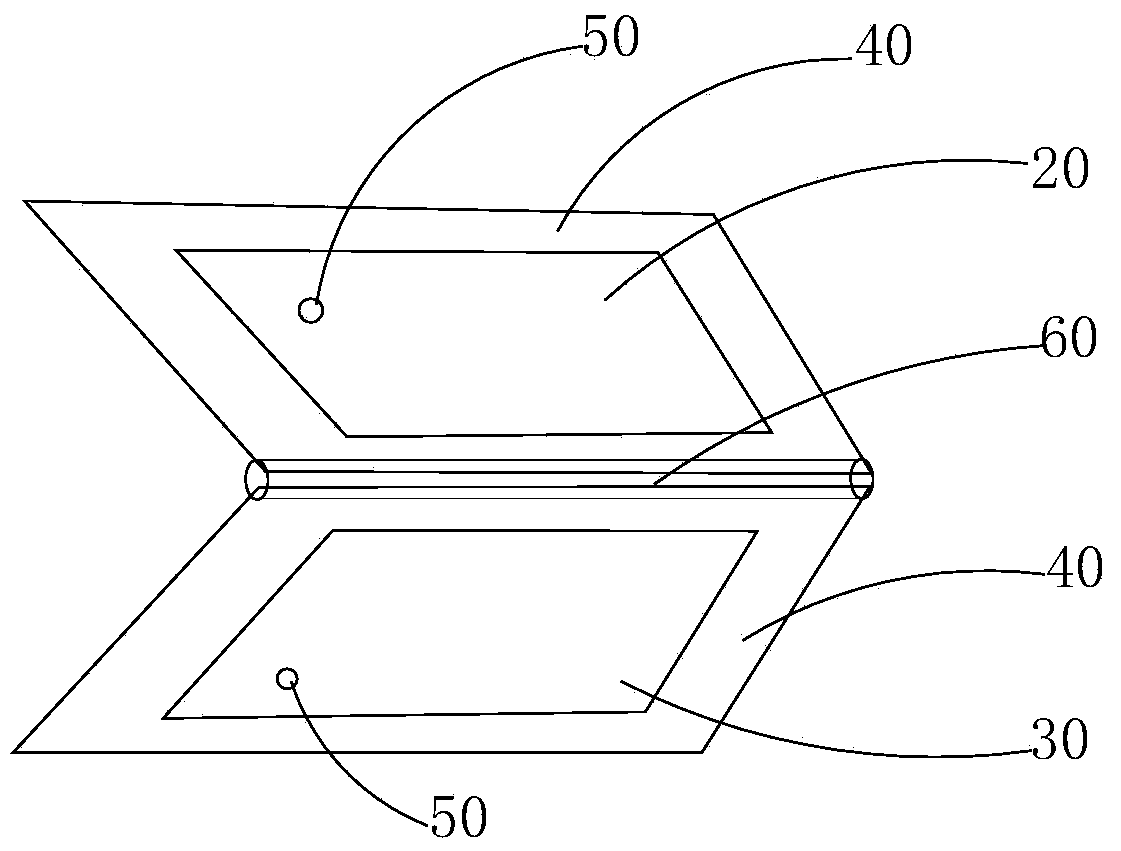

[0030] Such as figure 1 As shown, a test device for the short circuit risk between layers of a thin core board includes a withstand voltage tester 10, a first conductive plate 20, and a second conductive plate 30. A conductive plate 20 is electrically connected, and the negative electrode of the withstand voltage tester 10 is electrically connected to the second conductive plate 30 through a wire.

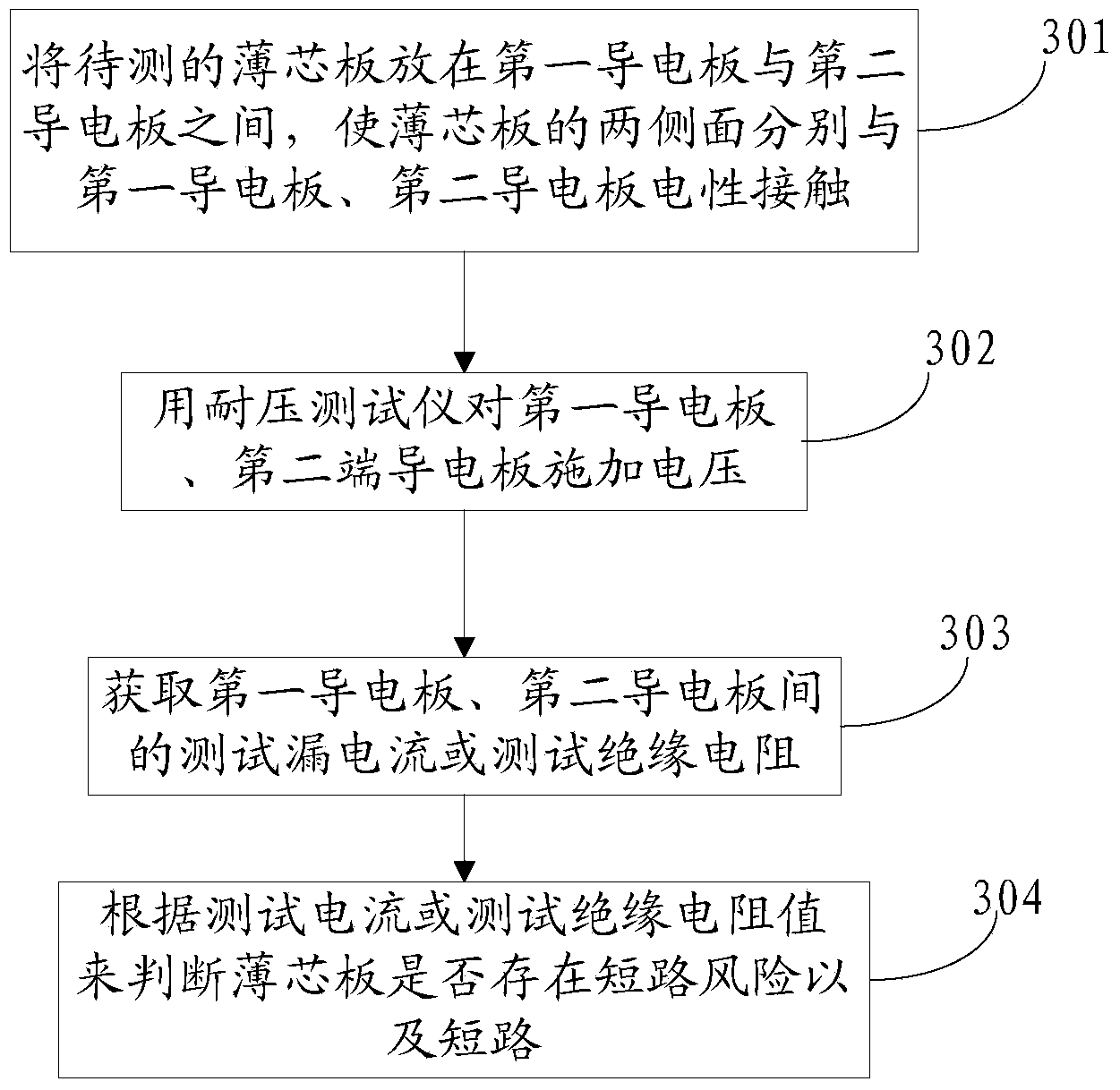

[0031] The two sides of the thin core plate are electrically contacted with the first conductive plate 20 and the second conductive plate 30 respectively, and positive voltage and negative voltage are respectively applied to the first conductive plate 20 and the second conductive plate 30, because the conductive plate and the thin core The board is in electrical contact, that is, a preset test voltage (such as 250V) is applied between the conductive patterns on both sides of the thin core board. It is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com