An improved battery glue injection device

A glue injection device and an improved technology, which is applied in the direction of alkaline storage batteries, battery pack parts, battery boxes/coats, etc., can solve the problems of easy damage of sealing rings, inability to spread evenly, inconvenient maintenance, etc., and achieve structural design Simple, improve work efficiency, reasonable structure and layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

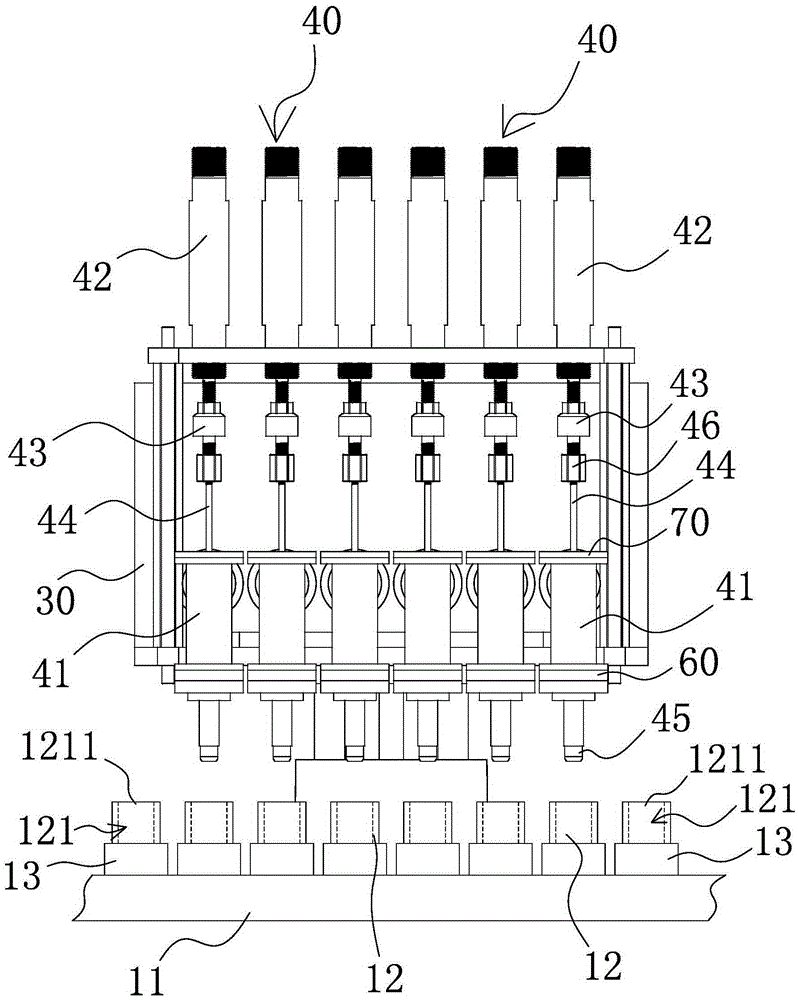

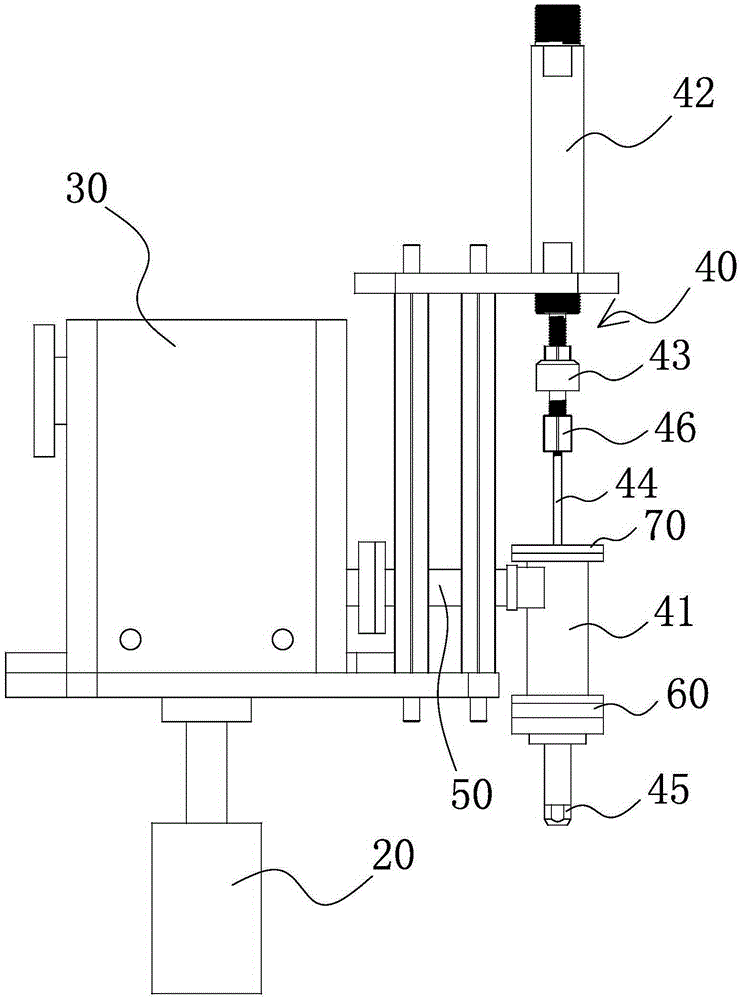

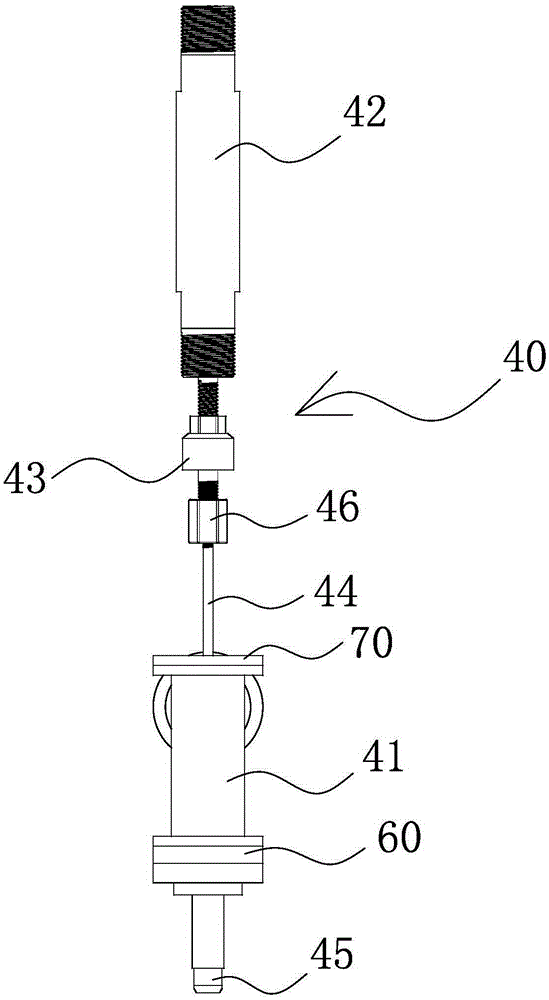

[0023] Such as Figure 1 to Figure 4 As shown, the improved battery glue injection device includes a carrier platform 20, a material tank 30 for storing glue, and a plurality of glue injection components 40 arranged in parallel at equal intervals. The material tank 30 is fixed on the carrier platform 20 and extends from the inside to the A stainless steel layer, a thermal insulation layer, and a shell layer are arranged on the outside in turn. The glue injection assembly 40 includes a glue injection pipe 41 fixed on the carrier 20 and a power part 42 corresponding to the glue injection pipe 41. In the middle of the glue injection pipe 41, there is a vertical The provided glue injection channel 411 and the glue injection ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com