Asymmetric double-side type permanent magnet straight line synchronous motor

A permanent magnet linear synchronization and asymmetric technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of thrust density limitation, poor heat dissipation conditions, and difficult processing, so as to reduce the consumption, avoid heat dissipation difficulties, and process convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

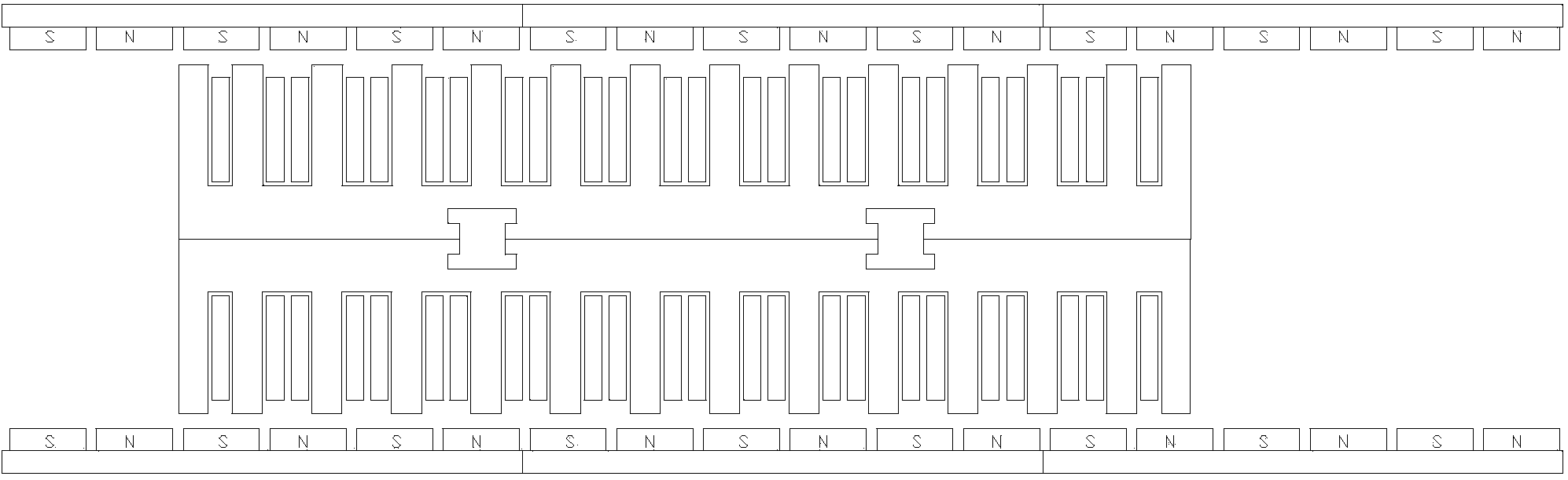

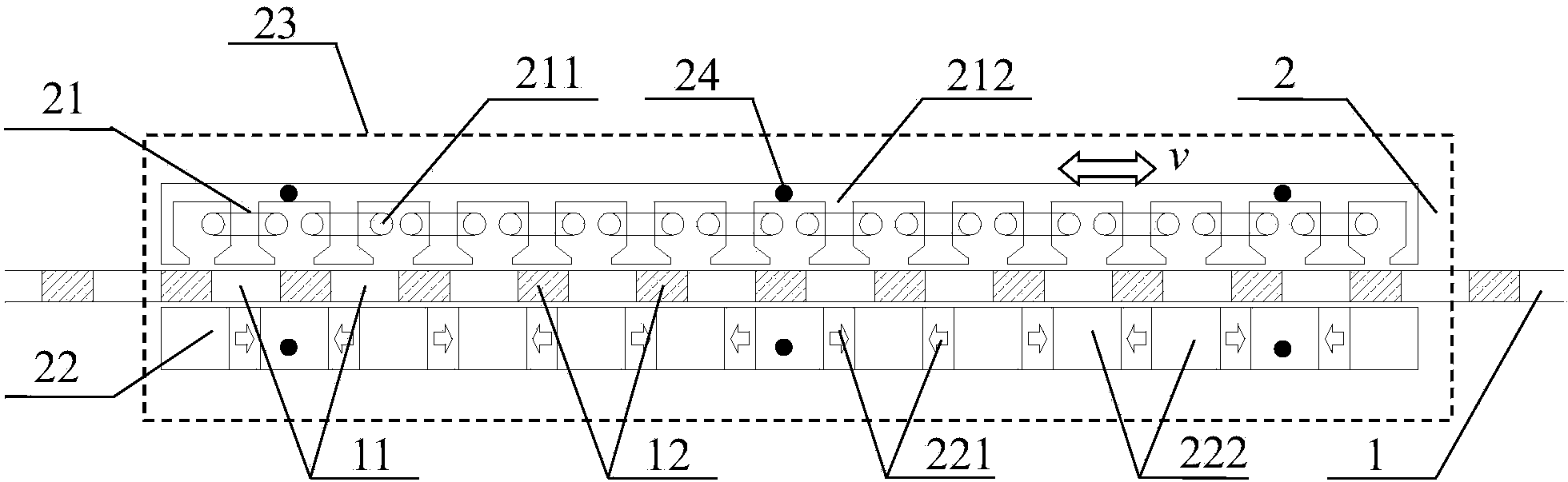

[0030] Such as figure 2 As shown, the asymmetric bilateral permanent magnet linear synchronous motor of this embodiment includes a long stator 1 and a short mover 2, and the short mover 2 includes an armature 21, a magnetic pole 22, a mobile platform 23 and mounting bolts 24, and the armature 21 Including armature winding 211 and armature core 212, the magnetic pole 22 is composed of permanent magnets 221 and magnetic pole cores 222 arranged alternately, the magnetization direction of adjacent permanent magnets is opposite, and the magnetization direction is consistent with the direction of motion, the armature 21 and the magnetic pole 22 Both are fixed on the mobile platform, both are relatively stationary, both are fixed below the mobile platform 23 by mounting bolts 24, and both sides maintain a certain air gap length with the long stator 1. The number of short mover armature slots is the same as the number of permanent magnet poles, and the permanent magnets are aligned w...

Embodiment 2

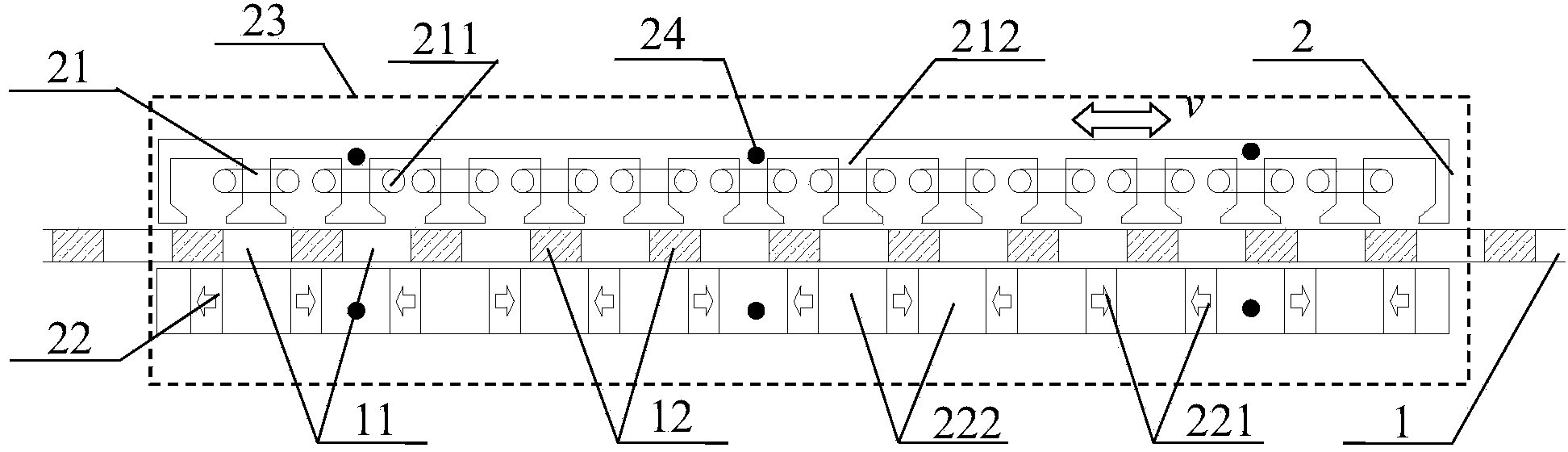

[0035] image 3 Shown is a kind of deformed structure of embodiment one, and figure 2 The difference is that the relative positions of the permanent magnet and the armature are different, and the permanent magnet is aligned with the armature slot in this implementation structure.

Embodiment 3

[0037] Such as Figure 4 As shown, the characteristics of this embodiment are: the permanent magnet 221 in the magnetic pole 22 is attached to the magnetic pole core 222, two permanent magnets are placed under each armature tooth, closely arranged, the polarity is opposite, and the magnetization direction is perpendicular to the direction of motion. , the magnetization directions of adjacent permanent magnets are opposite.

[0038] The working principle of the asymmetric bilateral permanent magnet linear synchronous motor in this embodiment is the same as that of the first embodiment. With the change of the position of the mover, the flux linkage in the armature winding is positive and negative alternately, which is basically sinusoidal and bipolar. magnetic chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com