Baked Composite Desserts with Inhibited Grease Transfer

A composite snack and baking technology, applied in the directions of edible oil/fat, baking, baked food, etc., can solve the problems of poor taste in the mouth, and achieve the effect of inhibiting whitening and good melting in the mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

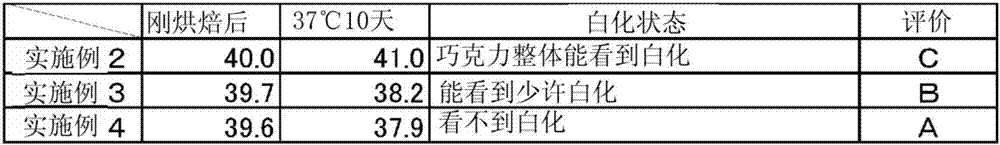

Examples

manufacture example 1

[0049] 27 parts by weight of whole milk powder, 3 parts by weight of skimmed milk powder, 33 parts by weight of granulated sugar, 5 parts by weight of lactose, 28 parts by weight of cocoa butter, 0.8 parts by weight of lecithin and 0.1 part by weight of spices are mixed, pulverized and refined according to the prescribed method, A chocolate base material having an oil content of 38% by weight was obtained. With 64 parts by weight of the obtained chocolate base material, 15 parts by weight of tempered cocoa butter substitute (CBE) whose SFC at 30°C is 18%, SFC at 20°C is 50%, and SFC at 10°C is 55%, 15 parts by weight of cocoa powder (oil content 12% by weight), 4 parts by weight of dextrin (trade name: TK-16, manufactured by Matsutani Chemical Industry Co., Ltd.) and 2 parts by weight of cocoa butter were mixed, and tempered according to the usual method , be shaped into a spherical shape and cooled and solidified to obtain spherical chocolate with an oil content of 42.0% by w...

manufacture example 2

[0051] 15 parts by weight of whole milk powder, 7.5 parts by weight of cream powder, 31 parts by weight of wheat flour, 22 parts by weight of sugar, 18 parts by weight of almond powder and 6.5 parts by weight of crystalline cellulose were mixed to obtain a powder mixture for coating. The oil content of the obtained powder mixture was 19% by weight.

manufacture example 3

[0053] 48 parts by weight of heated and melted butter, 47 parts by weight of vegetable oil, 0.5 parts by weight of gum arabic, and 0.5 parts by weight of sucrose fatty acid ester (trade name: Ryoto Sugar Ester ER-290, manufactured by Mitsubishi-Kagaku Foods Corporation) with an HLB of 2, 2 parts by weight of almond paste and 2 parts by weight of ammonium carbonate were mixed to obtain an oily liquid mixture. The obtained oily liquid mixture had an oil content of 88% by weight and a water content of 6.4% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com