Lubricating structure for linear compressor

A technology of linear compressors and lubricating structures, which is applied in mechanical equipment, machines/engines, liquid displacement machinery, etc. It can solve the problems of linear compressor performance degradation and high temperature, so as to suppress temperature rise, performance improvement, Avoid the effects of dry friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

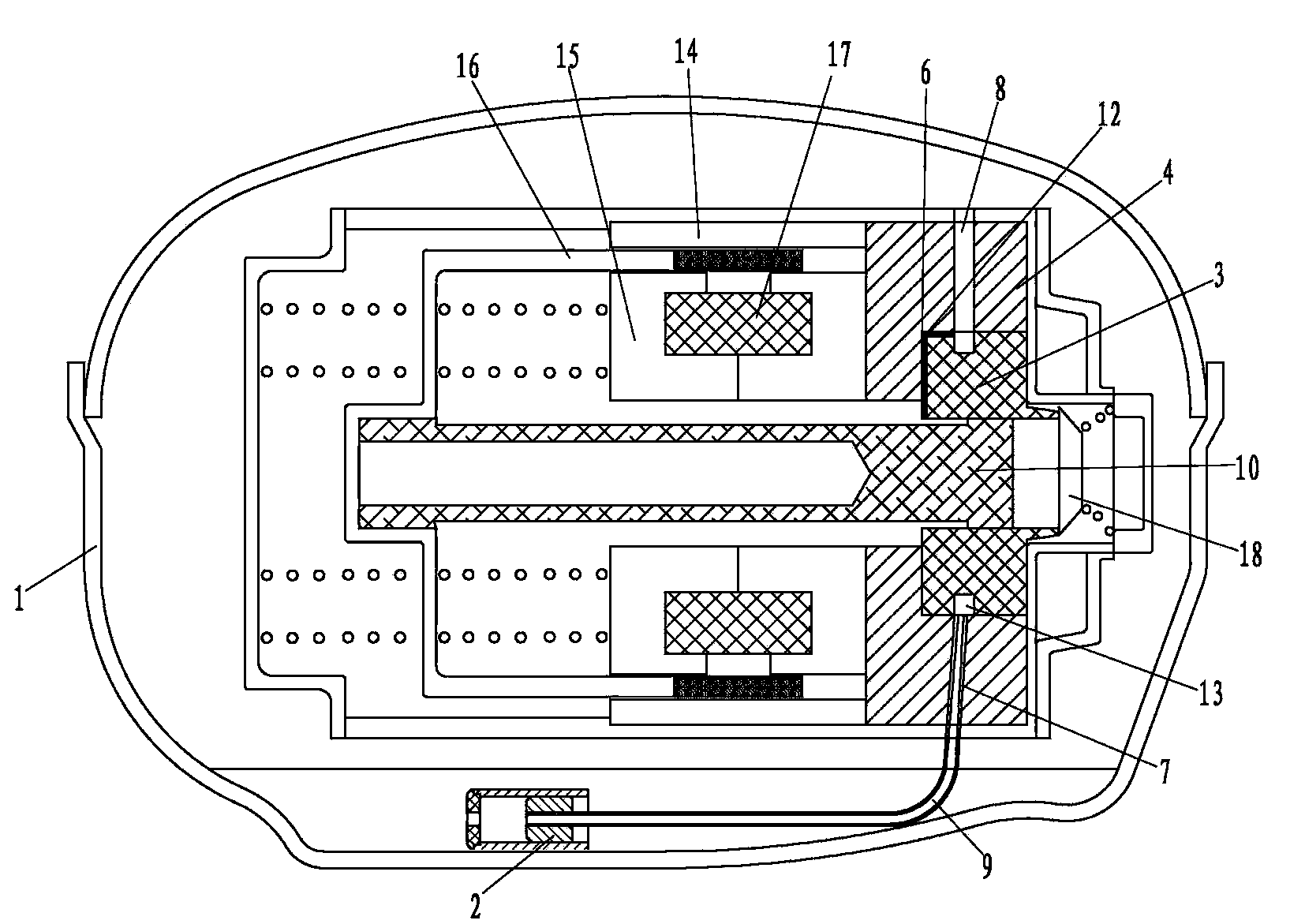

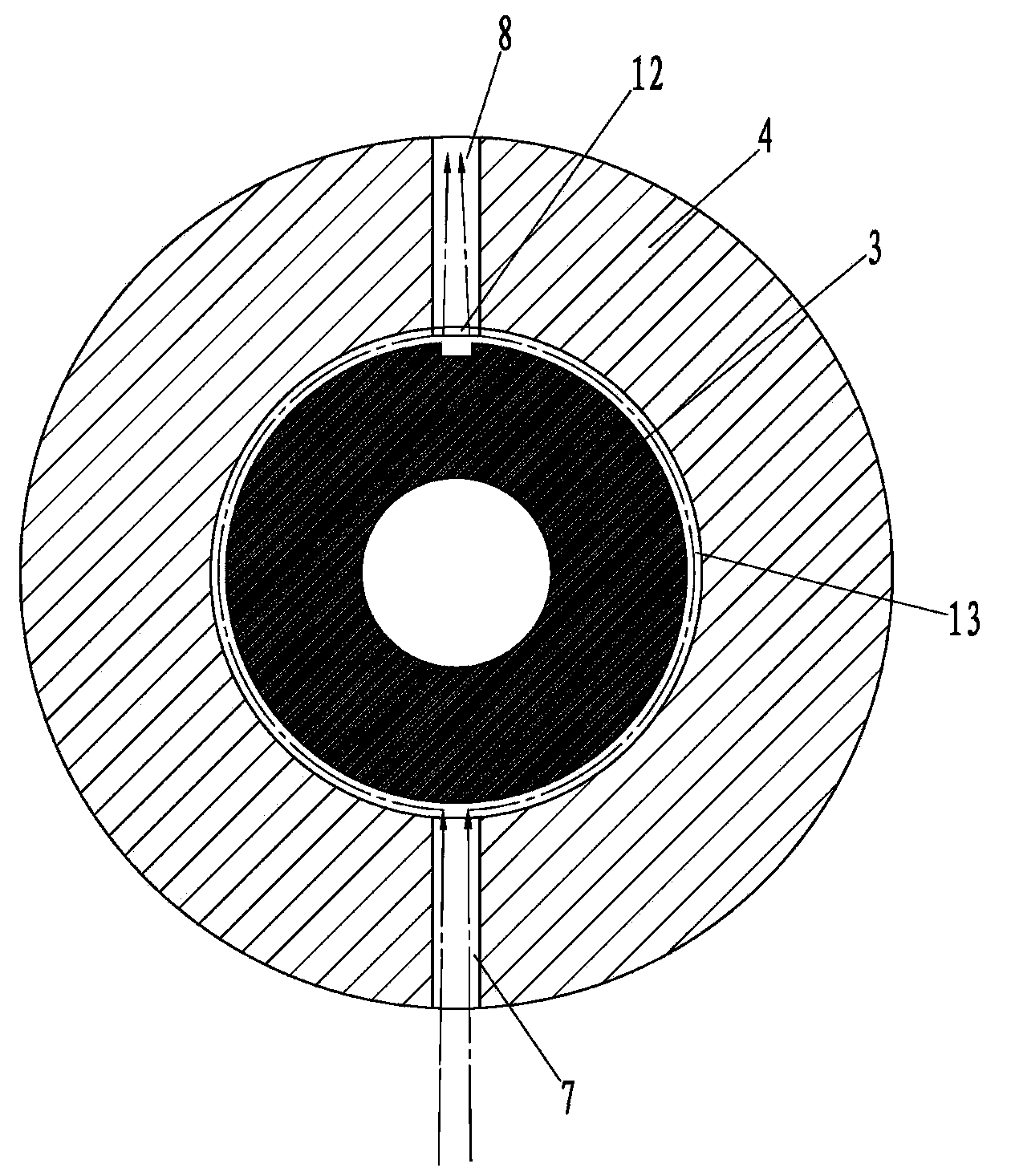

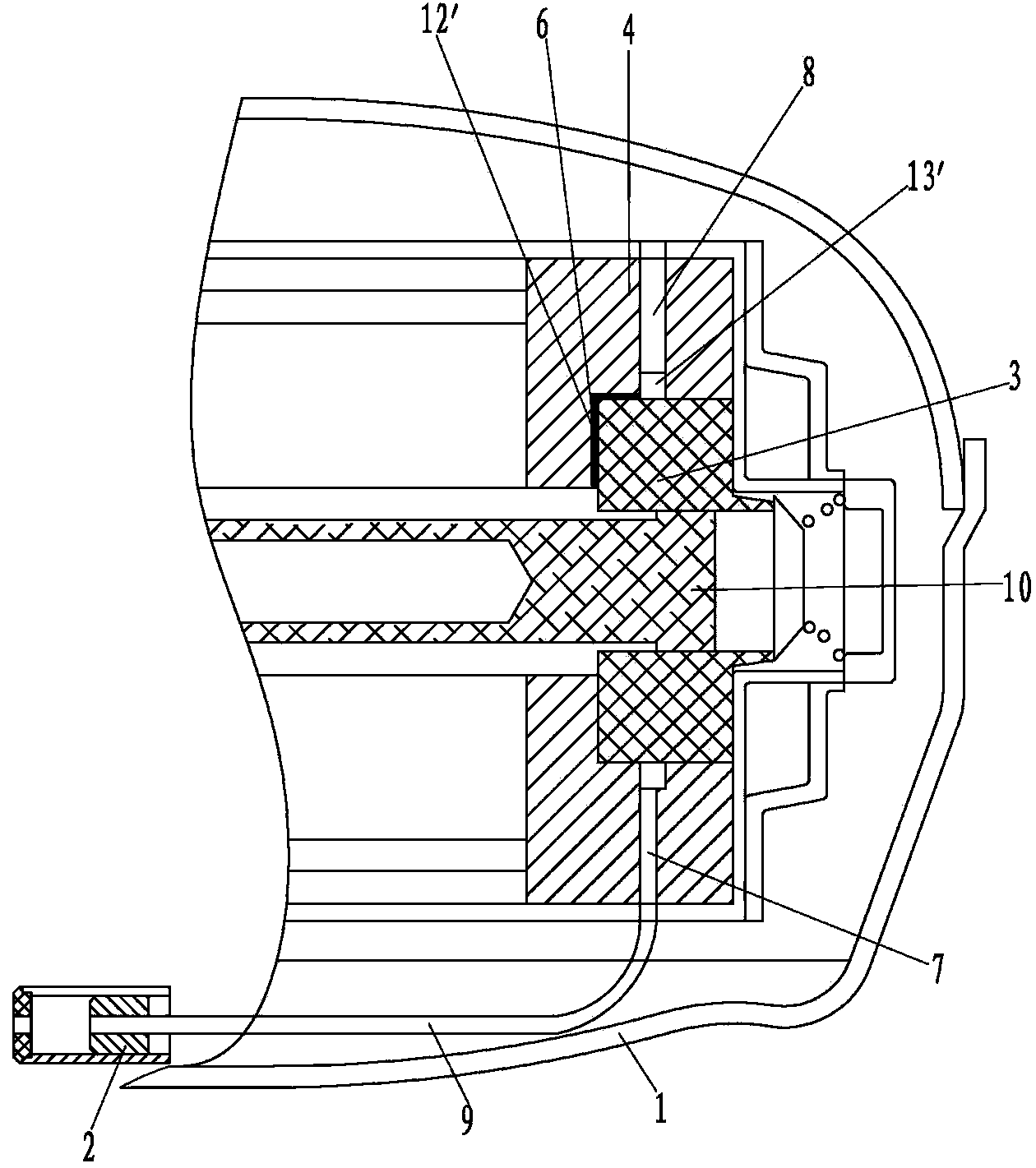

[0016] Such as figure 1 and figure 2 As shown, it is a structural schematic diagram of the first embodiment of the lubricating structure of the linear compressor of the present invention, including the shell 1, and lubricating oil is stored at the bottom of the inner cavity of the shell 1. The shell 1 is equipped with a cylindrical outer stator 14, the inner cavity of the outer stator 14 is provided with a cylindrical inner stator 15, the outer stator 14 and the inner stator 15 are coaxial, and a circle is inserted between the outer stator 14 and the inner stator 15. Cylindrical mover 16. The inner stator 15 has a built-in coil 17, and a coaxial piston 10 is arranged in the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com