Three-level power electronic traction transformer of non-power frequency transformer

A technology without power frequency transformers and traction transformers, applied in instruments, electrical components, regulating electrical variables, etc., can solve problems such as low voltage level, reduced system reliability, control and implementation difficulties, etc. The effect of improving work efficiency and power quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

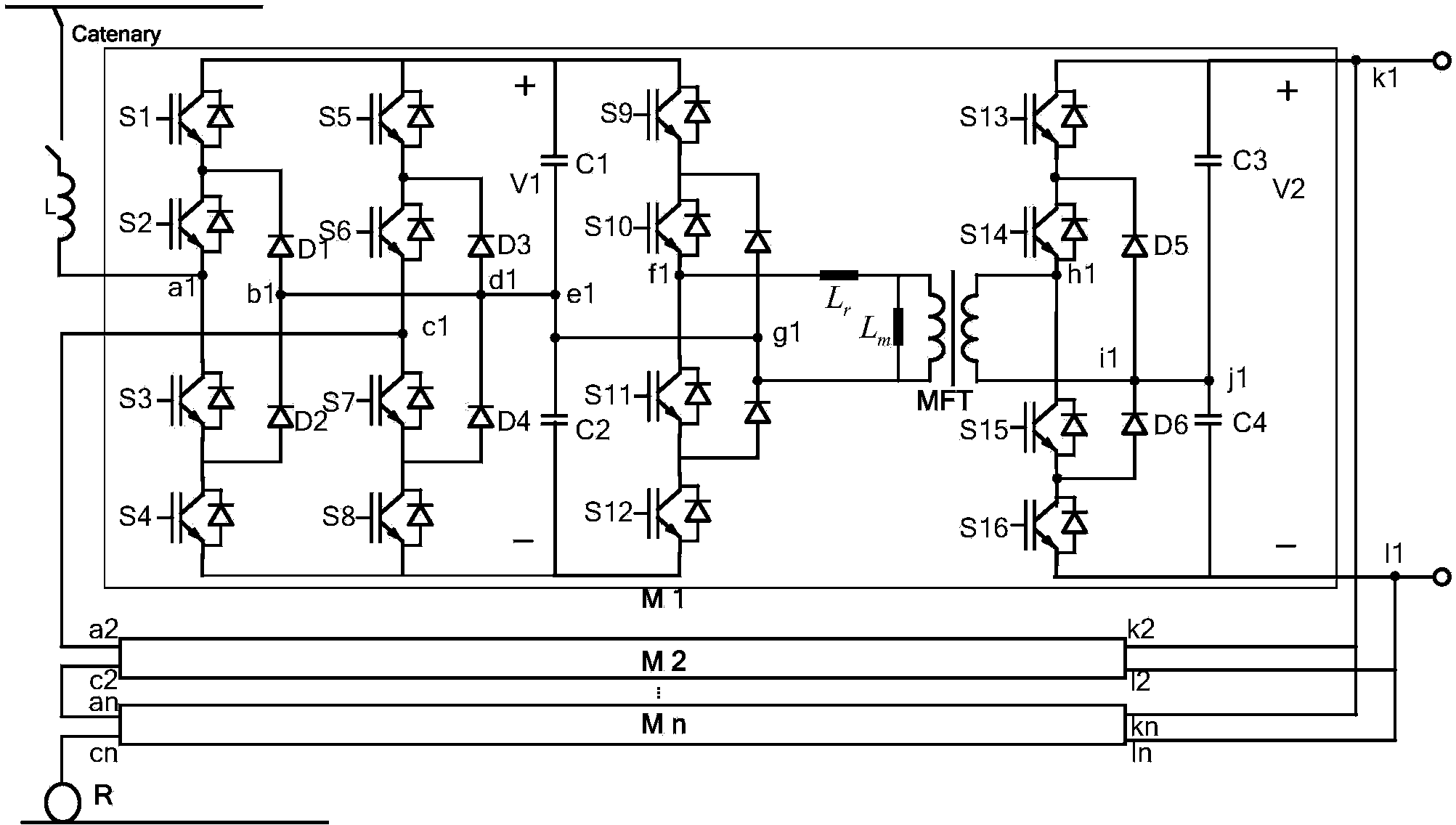

[0028] image 3 It is shown that a specific embodiment of the present invention is: a three-level power electronic traction transformer without a power frequency transformer, which realizes vehicle-mounted power transformation after being connected to the traction network (V) through an input reactor L, and consists of n The same functional block (M 1 -M n ), the module is a power electronic device of an AC-DC converter with a single-phase structure, characterized in that the power electronic device is mainly composed of a single-phase diode embedded three-level rectifier circuit, a half-bridge three-level two-way straight The converter consists of:

[0029] a. The left traction network (V) is connected to one end of the input reactor (L); the other end of the input reactor (L) is connected to the module 1 (M 1 ) The left bridge arm series switch tube (S 1 , S 2 , S 3 , S 4 ) midpoint a 1 ;Module 1(M 1 ) The right bridge arm series switch tube (S 5 , S 6 , S 7 , S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com