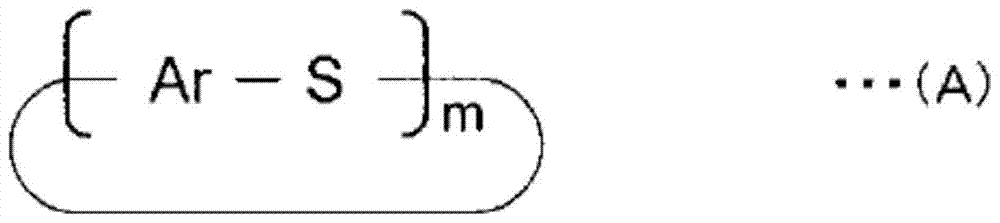

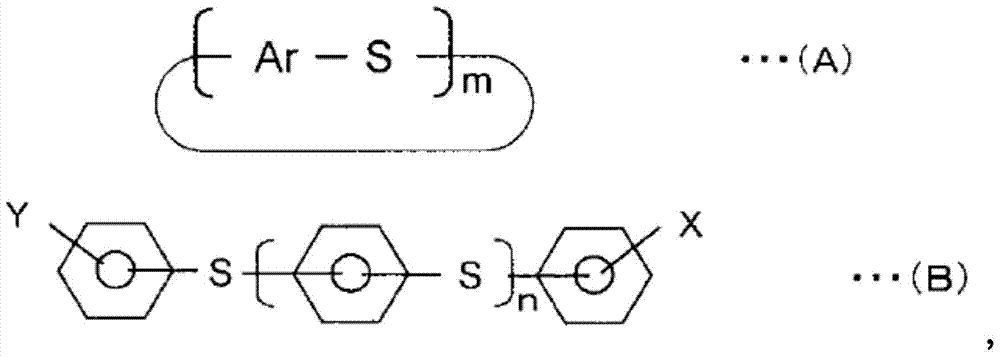

Polyarylene sulfide resin composition, method for producing the resin composition, and molded article of the resin composition

A technology for polyarylene sulfide and resin composition, which is applied in the field of polyarylene sulfide resin composition, can solve the problems of reduced gas generation, reduced reliability, and limited deployment, and achieves less gas generation and molding processing. Excellent properties and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0253]

[0254] Using polyarylene sulfide (A-1) as component (a), polyarylene sulfide (B-1) as component (b), and fibrous filler (F-1) as component (f), The polyarylene sulfide resin compositions of Examples 1-4 and Comparative Examples 1-4 were produced. When producing the PAS resin composition of each example and comparative example, (a) component, (b) component and (f) component were supplied to the Japan Steel Works Co. A TEX30α-type twin-screw extruder (L / D=45.5, 5 kneading sections) was produced. Specifically, the components (a) and (b) are supplied (main feed) from the main feeder of the extruder (distance L / D = 45.5 from the die), and the component (f) is supplied from the distance from the die At L / D=15, it is supplied from the middle using a side feeder (side feed). Moreover, when using both (a) component and (b) component, both are dry-blended before main feeding. Using the above-mentioned extruder, the screw speed was 300 rpm, the barrel temperature was set so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com