Lithium metal composite oxide, lithium secondary battery positive electrode active material, positive electrode, and lithium secondary battery

A composite oxide and lithium secondary battery technology, which is applied in the direction of active material electrodes, secondary batteries, battery electrodes, etc., can solve the problems of easy power drop and battery internal resistance rise, and achieve less gas generation and low battery resistance , The effect of excellent power characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

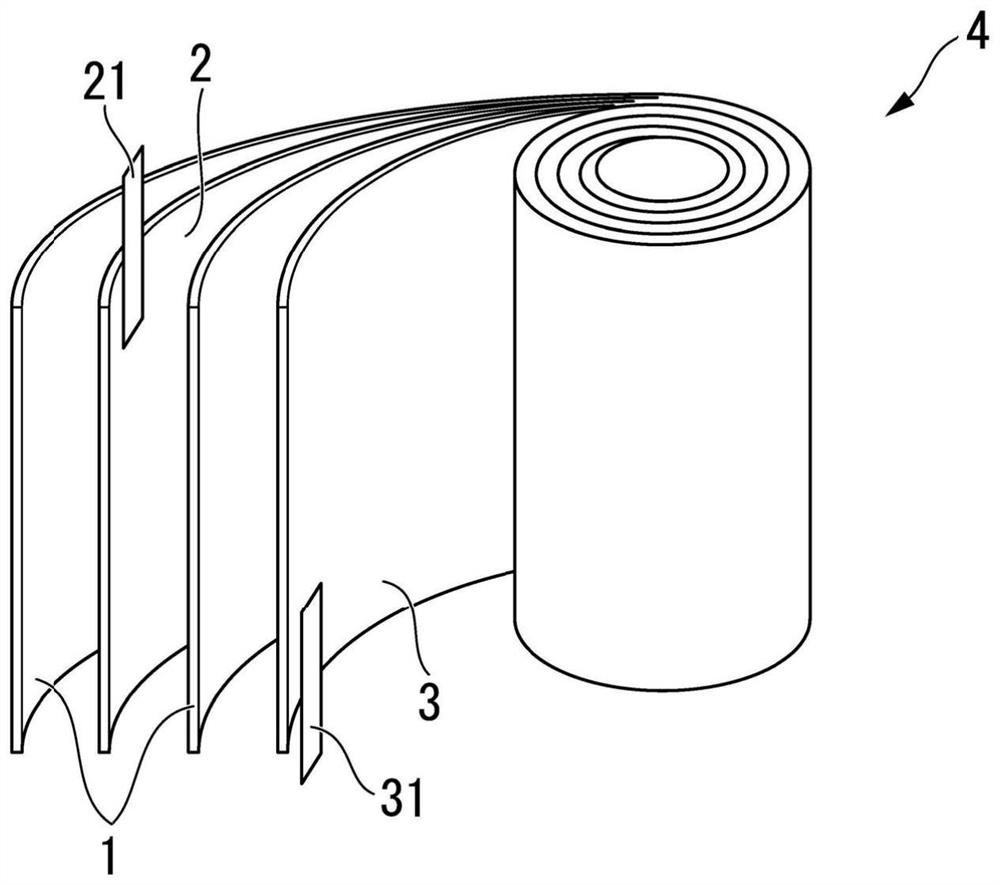

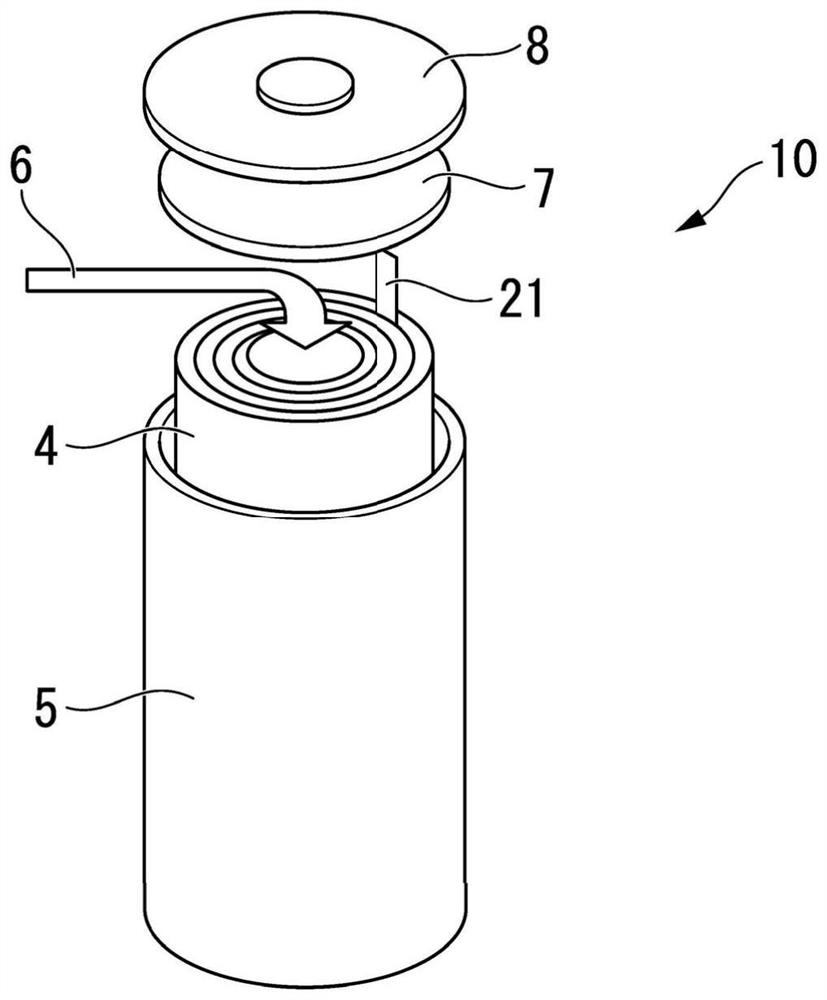

Method used

Image

Examples

Embodiment 1

[0242] Manufacture of positive electrode active material 1 for lithium secondary battery

[0243] [Manufacturing process of nickel-cobalt-manganese composite hydroxide]

[0244] After adding water to the reaction tank equipped with a stirrer and an overflow pipe, sodium hydroxide aqueous solution was added, and liquid temperature was maintained at 50 degreeC.

[0245] An aqueous nickel sulfate solution, an aqueous cobalt sulfate solution, and an aqueous manganese sulfate solution were mixed such that the atomic ratio of nickel atoms, cobalt atoms, and manganese atoms was 0.510:0.225:0.265, thereby preparing a mixed raw material solution.

[0246] Next, the mixed raw material solution and an aqueous solution of ammonium sulfate as a complexing agent were continuously added to the reaction tank under stirring so that the pH of the solution in the reaction tank when measured at 40° C. became 11.75. Aqueous sodium hydroxide solution was added. Then, feed an oxidizing gas mixed w...

Embodiment 2

[0254] Manufacture of positive electrode active material 2 for lithium secondary battery

[0255] [mixing process]

[0256] The nickel-cobalt-manganese composite hydroxide 1 and lithium carbonate powder were weighed and mixed so that the molar ratio became Li / (Ni+Co+Mn)=1.07.

[0257] [Firing process]

[0258] The mixture obtained in the above mixing step was fired at 930° C. for 5.6 hours under an oxygen atmosphere, thereby obtaining a fired product 2 .

[0259] [Coating process]

[0260] The calcined product 2 and alumina were weighed and mixed so that Al / (Ni+Co+Mn)=0.01, and heat-treated at 760° C. for 5 hours in an atmosphere to obtain a positive electrode active material for a lithium secondary battery 2.

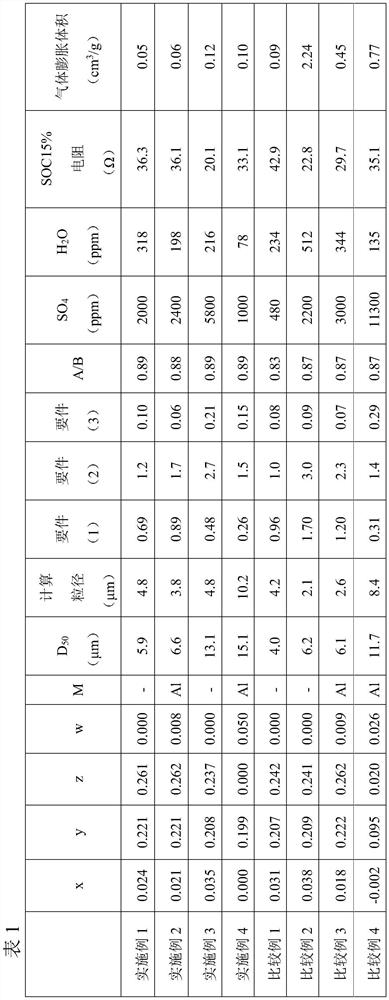

[0261] Evaluation of Positive Electrode Active Material 2 for Lithium Secondary Batteries

[0262] Composition analysis was performed on the obtained positive electrode active material 2 for lithium secondary batteries, and when it corresponded to composition formul...

Embodiment 3

[0264] Manufacture of positive electrode active material 3 for lithium secondary battery

[0265] [Manufacturing process of nickel-cobalt-manganese composite hydroxide]

[0266] Except having mixed so that the atomic ratio of nickel atom, cobalt atom, and manganese atom might become 0.550:0.210:0.240, it carried out similarly to Example 1, and prepared the mixed raw material liquid.

[0267] Next, the mixed raw material solution and an aqueous solution of ammonium sulfate as a complexing agent were continuously added to the reaction tank under stirring so that the pH of the solution in the reaction tank when measured at 40° C. became 10.54. Aqueous sodium hydroxide solution was added. Then, feed an oxidizing gas mixed with nitrogen and air to adjust the various liquid amounts so that the reaction time becomes 20.1 hours to obtain nickel-cobalt-manganese composite hydroxide particles. After washing, it was dehydrated and separated with a centrifuge, and dried at 105° C., wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com