Carbon materials for lithium-ion secondary batteries

A secondary battery, lithium ion technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problem of irreversible capacity increase, and achieve the effects of excellent high temperature storage characteristics, less gas generation, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

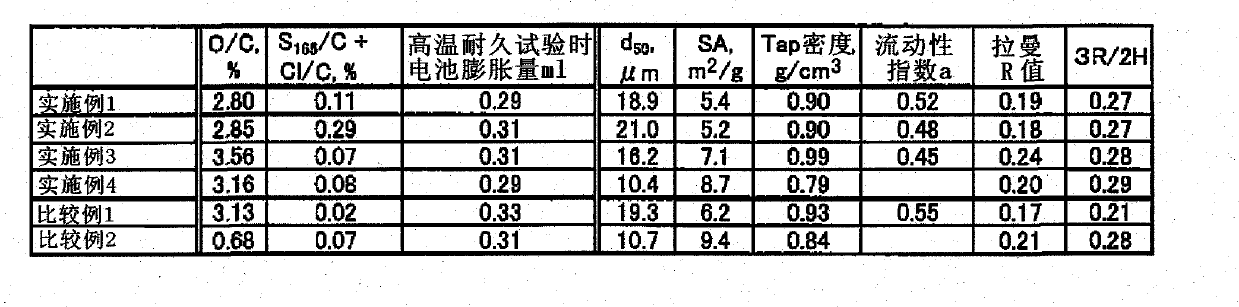

Embodiment 1

[0183] With the spherical natural graphite that measures in the above-mentioned measuring method, surface functional group amount O / C value is 2.90% in the mixed acid solution of concentrated hydrochloric acid (33wt%) and concentrated nitric acid (40wt%) (concentrated hydrochloric acid: concentrated nitric acid (weight ratio) =1:1) at 80°C for 4 hours, washed with pure water until the pH became 4 or more, and filtered. Furthermore, the sample obtained here was stirred in concentrated sulfuric acid (93 wt%) at 80° C. for 4 hours, washed with pure water until the pH became 4 or higher, and then kept at 300° C. for 6 hours to obtain a sample. Measure particle size d50, tap density, BET specific surface area (SA), Raman R value, surface functional group amount O / C value, surface functional group amount S 165 / C value, Cl / C value of surface functional groups, 3R / 2H, fluidity index a, expansion of laminated battery during 24-hour high-temperature endurance test at 85°C (referred to ...

Embodiment 2

[0185] The spherical natural graphite measured in the above-mentioned measuring method, the surface functional group amount O / C value is 3.04% in the mixed acid solution of concentrated hydrochloric acid and concentrated nitric acid (concentrated hydrochloric acid: concentrated nitric acid (weight ratio)=1: 1) at 80 The mixture was stirred for 8 hours at °C, washed with pure water until the pH became 4 or more, and filtered. Furthermore, the sample obtained here was stirred in concentrated sulfuric acid at 80° C. for 4 hours, washed with pure water until the pH became 4 or higher, and then kept at 300° C. for 6 hours to obtain a sample. The same measurement as in Example 1 was performed on this. The results are shown in Table 1.

Embodiment 3

[0187] The spherical natural graphite measured in the above-mentioned measuring method, the surface functional group amount O / C value is 3.66% in the mixed acid solution (concentrated hydrochloric acid: concentrated nitric acid (weight ratio)=1: 1) of concentrated hydrochloric acid and concentrated nitric acid at 80 °C for 2 hours, washed with pure water until the pH became 4 or more, and filtered. Furthermore, the sample obtained here was stirred in concentrated sulfuric acid at 80° C. for 2 hours, washed with pure water until the pH became 4 or higher, and then kept at 300° C. for 6 hours to obtain a sample. The same measurement as in Example 1 was performed on this. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com