Straw and biogas slurry synchronous returning method and machine

A technology for straw and biogas slurry, which is applied in the field of farmland preparation technology and machinery and tools, can solve the problems of lignification, serious fibrosis, slow degradation, and difficulty in rotting and degradation, and achieves the effect of improving the degradation speed and effect, and tight burial.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

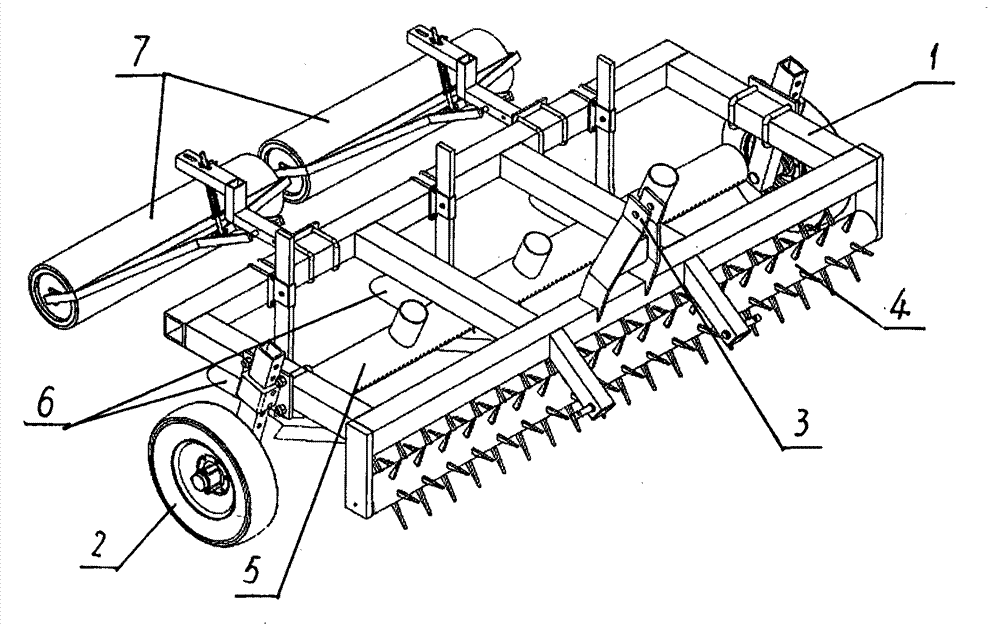

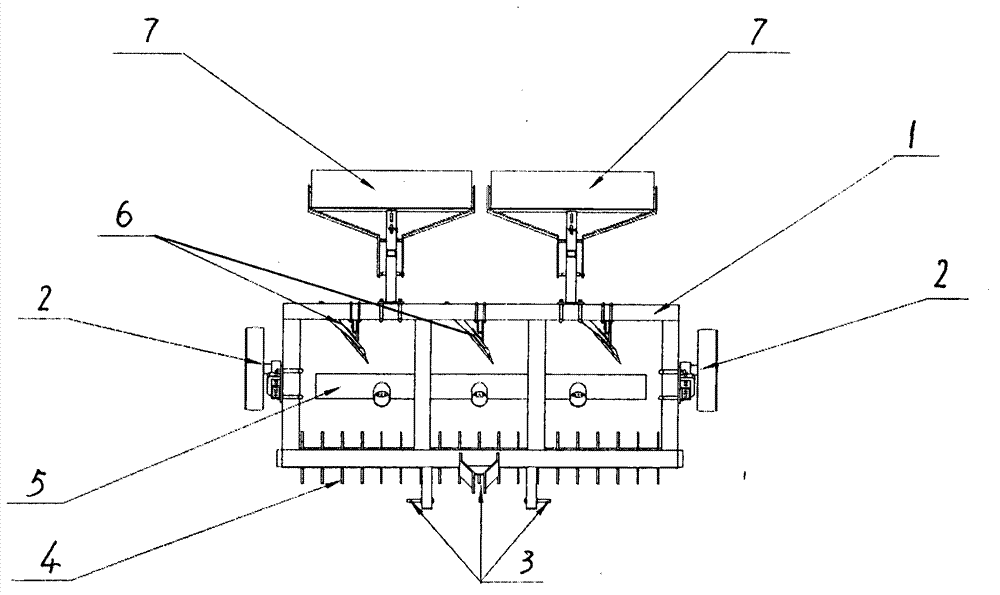

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A machine tool for synchronously returning straw and biogas slurry to the field includes a frame assembly 1, and a three-point suspension assembly 3 and a straw and stubble crushing knife shaft assembly are respectively installed on the upper and lower parts of the front side of the frame assembly 1. 4, the two road wheel assemblies 2 are fitted on the left and right sides of the frame assembly 1 respectively, on the frame assembly 1, behind the straw and stubble crushing knife shaft assembly 4, from the front to the After that, the biogas slurry spraying assembly 5, the plow assembly 6 and the pressing assembly 7 are arranged and installed in sequence.

[0016] During operation, the straw and stubble crushing knife shaft assembly 4 on the simultaneous return of straw and biogas slurry to the field machine completes the crushing and processing of the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com