Double-closed-loop redundancy pressure control system of coil hydraulic press

A redundant control, hydraulic press technology, applied in the field of coil hydraulic presses, can solve the problems of low pressure accuracy, coil damage, poor stability, etc., and achieve the effects of strong real-time performance, stable and reliable pressure, and high pressure control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

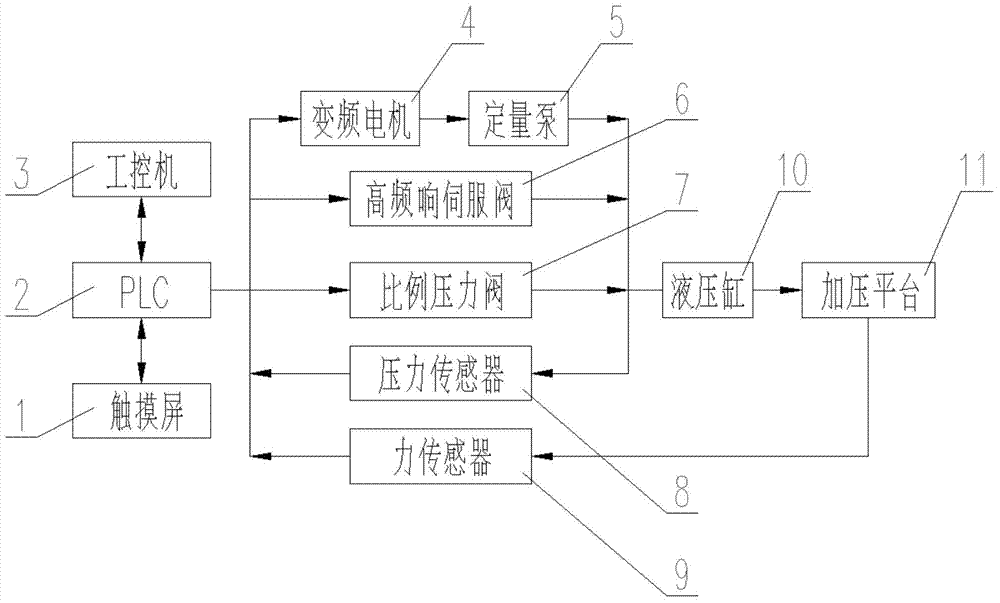

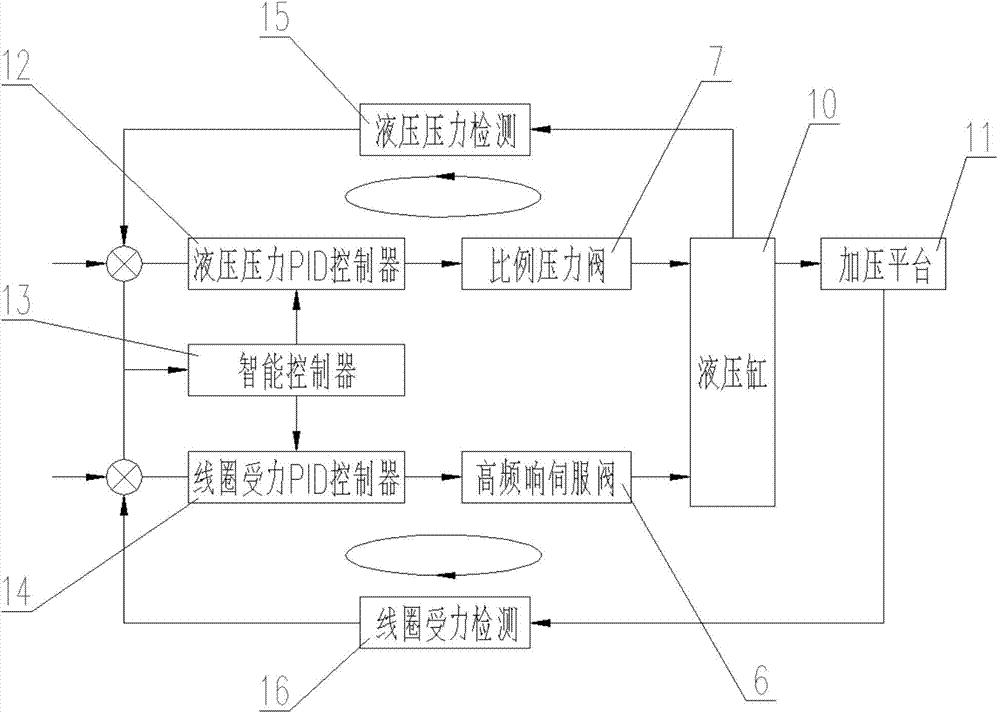

[0017] see figure 1 , The coil hydraulic press pressure double closed-loop redundant control system provided in this embodiment includes a PLC (programmable controller) 2 for controlling the coil hydraulic press, a touch screen 1 for exchanging parameters with the PLC2 through the Profibus field bus, and an industrial Ethernet and PLC2 The industrial computer 3 for exchanging complex arithmetic functions, the PLC2 is connected with one end of the variable frequency motor 4, the high-frequency response servo valve 6 and the proportional pressure valve 7 controlled by it, and the other end of the variable frequency moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com