Automatic workpiece conveying device

A technology of automatic conveying device and workpiece, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of low efficiency and high labor intensity of workers, and achieve the effect of saving labor, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

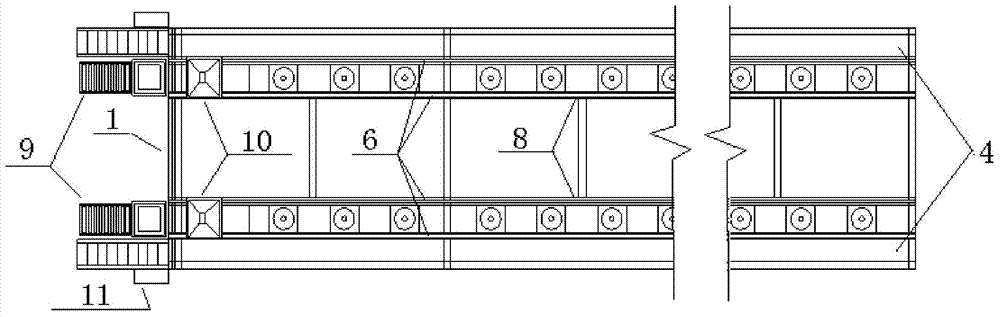

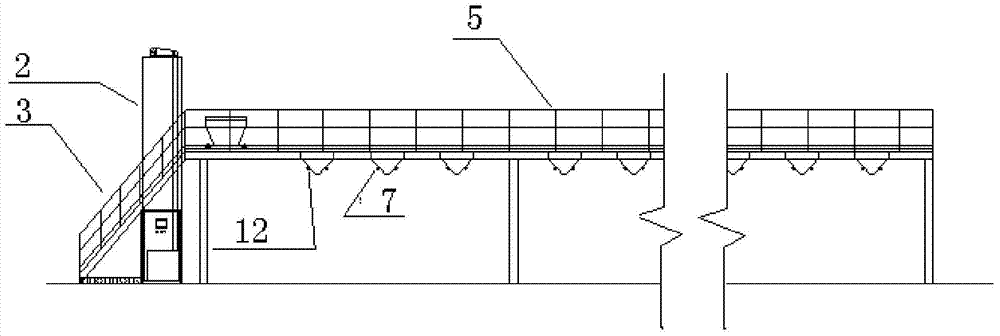

[0016] Such as Figure 1 ~ Figure 2 As shown, an automatic workpiece conveying device, which sends the parts to be processed to the required station through the automatic feeding conveying line, including the steel frame main body 1, the feeding lifting device 2, the escalator 3, the pedestrian passage 4, and the handrail 5 , Track 6, hopper 7, wire trough 8, raceway 9, feeding trolley 10, electrical control system box 11, on-shooting sensor switch 12 and other related accessories.

[0017] If the hopper alarm light of the 6th station hopper 7 flickers, it means that the hopper shooting sensor switch 12 detects that there is no material in the hopper, and then prepares for feeding.

[0018] Put the parts to be processed into the iron drum turnover box, and the iron drum turnover box is transported to the raceway 9 with a forklift, and the forklift exits, and the iron drum turnover box on the raceway 9 rolls smoothly into the feeding lifting device 2, and then Find the station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com