Method for preparing garbage derived fuel and diesel fuel from city garbage

A garbage-derived fuel and municipal garbage technology is applied in the field of municipal garbage to produce garbage-derived fuel and diesel, which can solve the problems of bad viscous organic matter in the engine and hidden dangers in use, and achieve the goal of overcoming the waste of valuable garbage, simplifying steps, and advanced technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

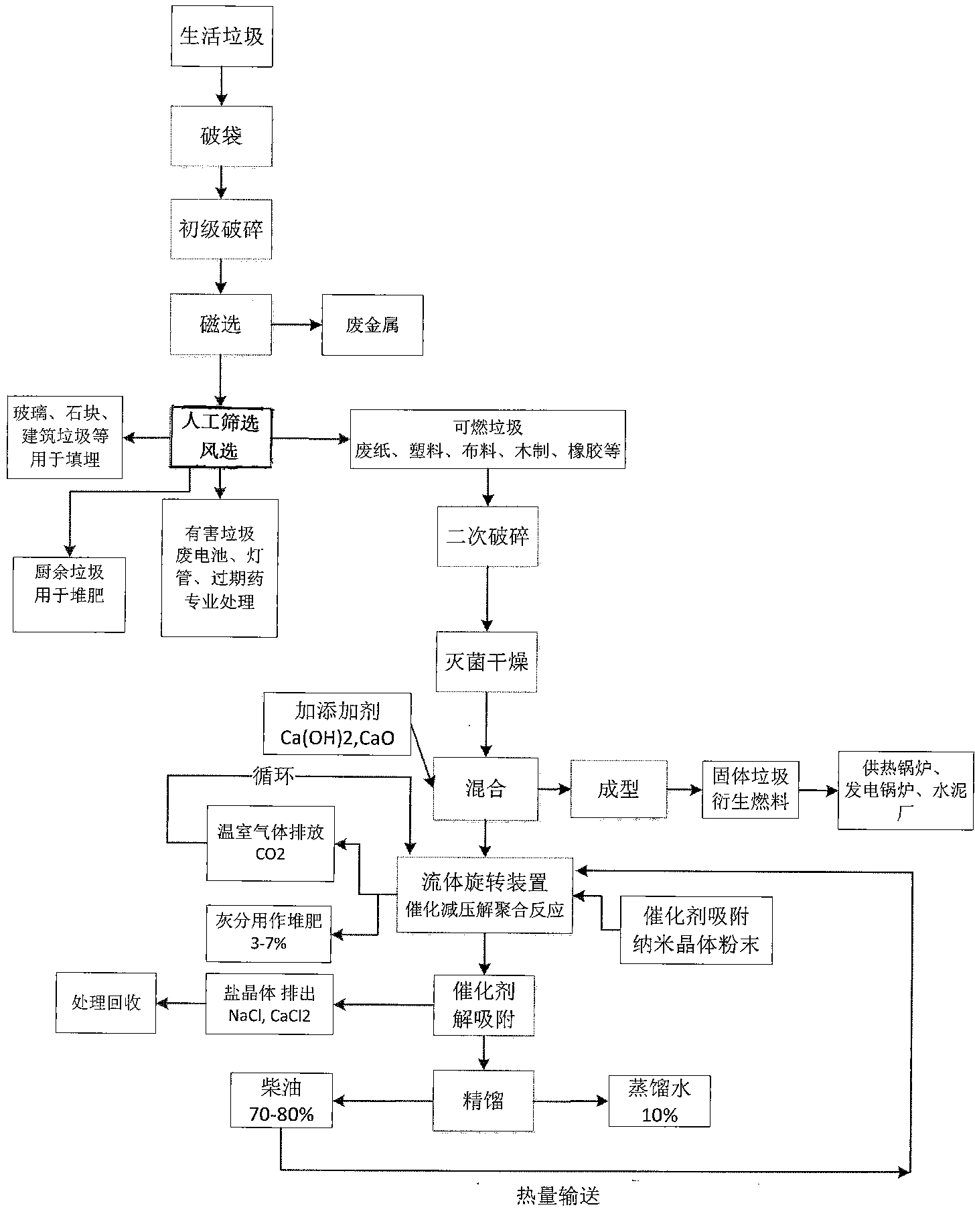

[0027] A method for producing refuse-derived fuel and diesel from municipal refuse, comprising the following steps:

[0028] (1) Bag breaking process: bagged garbage is broken and rolled;

[0029] (2) Primary crushing process: Primary crushing of the garbage mixture into smaller pieces with a diameter of 2-4 cm by crushing equipment;

[0030] (3) Magnetic separation process: separate and remove scrap metal substances from the above mixture fragments;

[0031] (4) Manual screening and winnowing process: The primary crushed materials obtained in the above steps are first manually screened to select kitchen waste and harmful waste substances, and then carried out winnowing to screen out inorganic waste solids and combustibles; the screened Combustibles are transferred to the following processes;

[0032] (5) Secondary crushing: Secondary crushing of the combustible waste obtained above into fine pieces with a diameter of 3-8mm;

[0033] (6) Sterilization and drying: Sterilize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com