Conveyor unloading part rear-mounted end hydraulic support

A technology of end hydraulic supports and unloading parts, which is applied in mine roof supports, mining equipment, earthwork drilling and mining, etc. It can solve problems such as failure to meet layout requirements, difficulty in left and right adjustment, and inability to use effectively, so as to reduce labor intensity of workers, Flexible, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

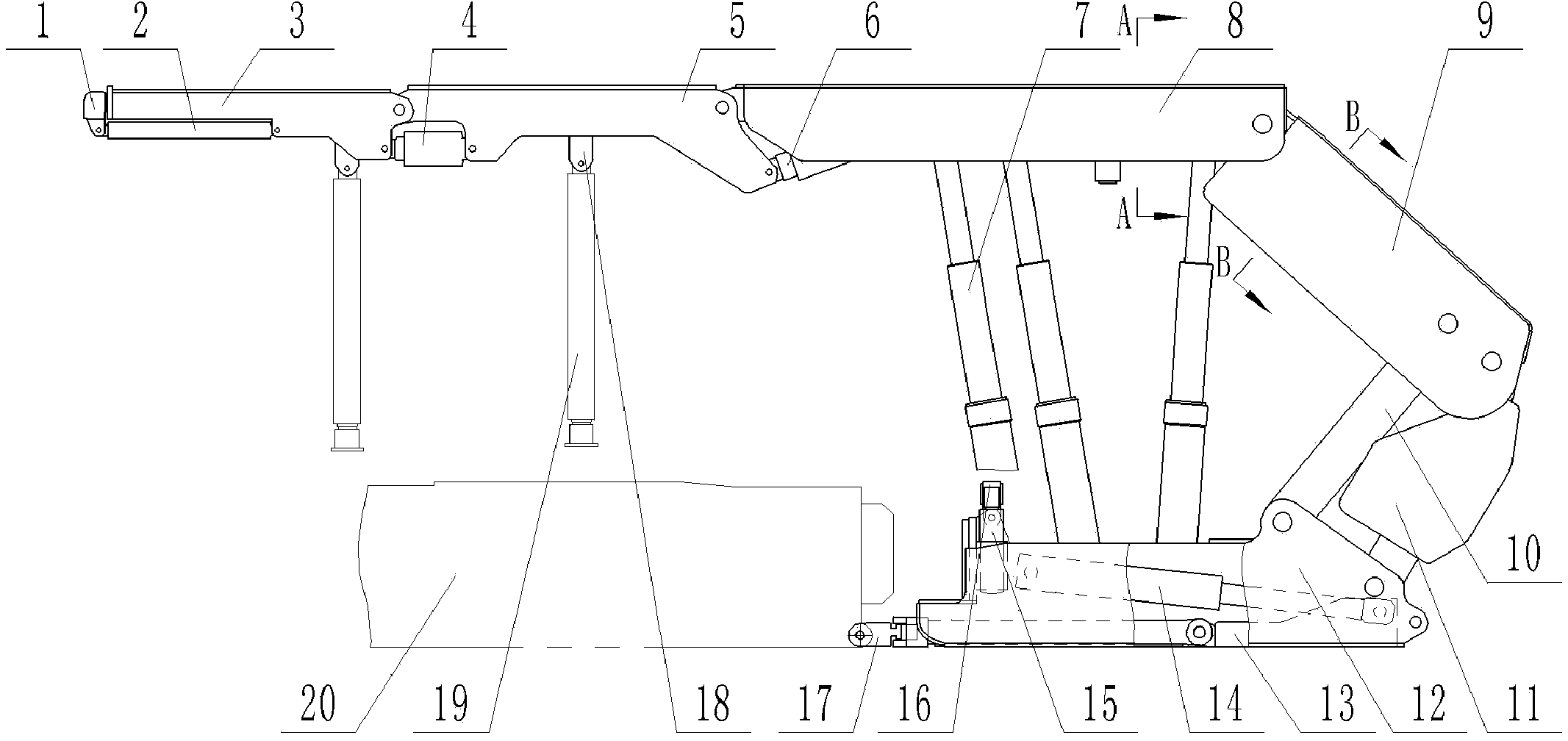

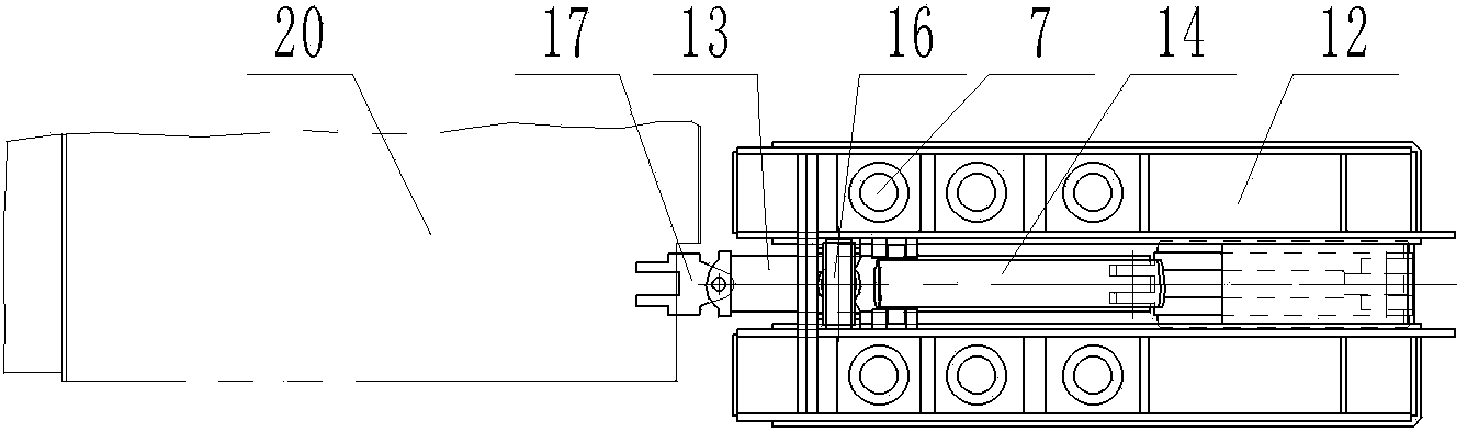

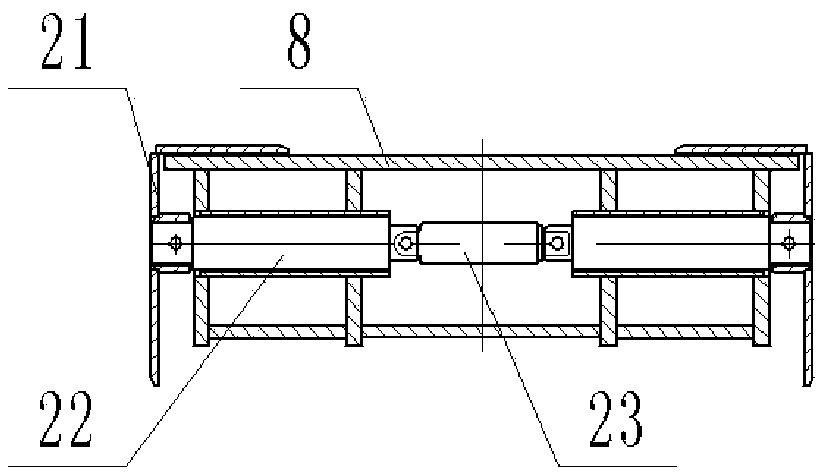

[0026] Such as Figure 1 to Figure 5 As shown, a post-mounted end hydraulic support of the unloading part of the conveyor includes a base 12, a top beam, a hydraulic column 7, a cover beam 9, and front and rear connecting rods. The top beam is composed of a middle top beam 5 and a rear top beam 8 ; For the purpose of ensuring that the present invention is stable and stable in support, the base 12 is hinged with one end of the shield beam 9 through the front and rear links respectively, and the base 12, the shield beam 9 and the front and rear links form a four-link Mechanism; the other end of cover beam 9 is hinged with one end of back top beam 8, and the other end of rear top beam 8 is hinged with the rear end of middle top beam 5, and between middle top beam 5 and back top beam 8 is provided with Middle roof beam hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com