Cylindrical channel type underwater multiphase jet noise reduction and noise reduction device

A cylindrical and channel technology, which is applied in the field of cylindrical channel underwater multiphase jet noise reduction and noise reduction devices, can solve the problems of multiphase jet noise reduction devices that have not been found, and achieve the effect of compact structure and elimination of air flow pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

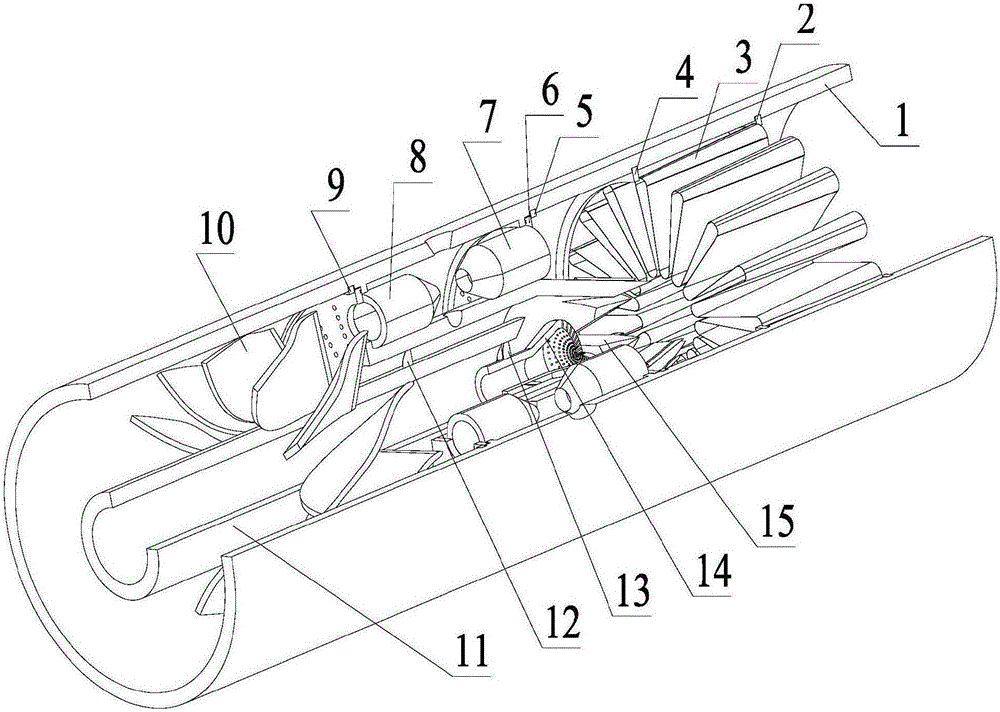

[0040] figure 1 The overall figure shown has: shell 1, outlet inner snap ring 2, flower-shaped folded guide pipe 3, positioning inner snap ring 4, rear snap ring 5, annular orifice plate 6, rear nozzle pipe 7, front Arranged nozzle 8, front snap ring 9, blade 10, inner conduit 11, front finned plate 12, rear finned tube 13, multi-hole nozzle 14, tapered V-shaped nozzle 15.

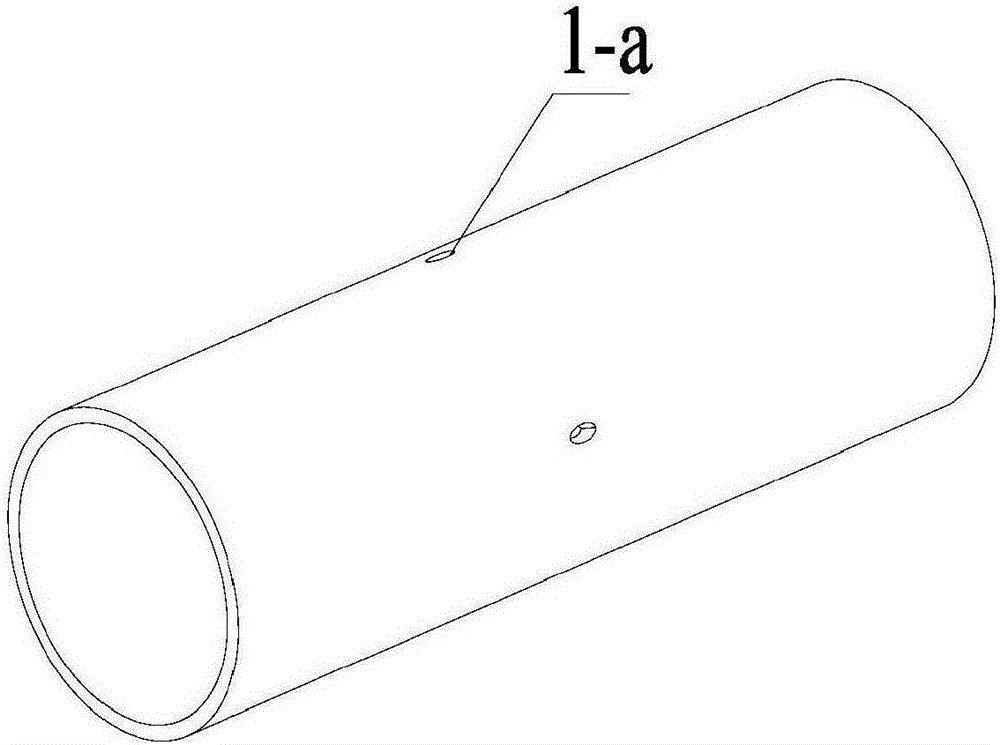

[0041] The shell 1 is the shell of the underwater multiphase jet noise reduction and noise reduction device, and all components are wrapped in it;

[0042] The flower-shaped folded guide tube 3 is installed on the outlet end of the housing 1, and is positioned by the outlet inner snap ring 2 and the positioning inner snap ring 4;

[0043] The four corresponding round holes on the front side of the ring plate of the annular orifice plate 6 are welded with the rear nozzle 7, and the annular orifice plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com