Ultrahigh pressure pilot operated relief valve

A pilot-operated relief valve, ultra-high pressure technology, applied to valve details, safety valves, balance valves, etc., can solve problems such as short service life, overflow valve scrapping, frequent replacement, etc., achieve good wear resistance and prolong service life The effect of improving the service life and the strength of the valve seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

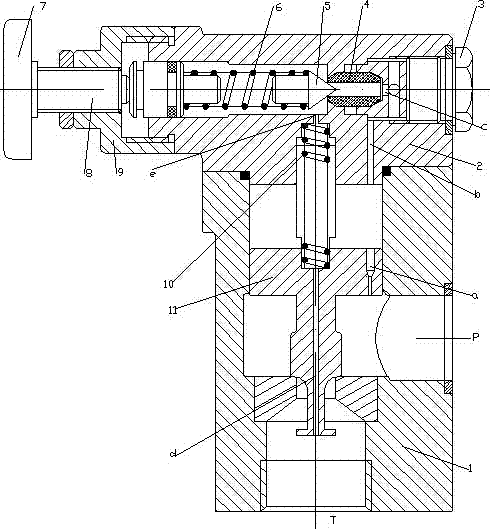

[0016] Embodiment 1: as figure 1 In the ultra-high pressure pilot relief valve shown, the ultra-high pressure fluid enters the main valve (1) from the inlet (P), and passes through the orifice (a), the channel (b) and the radial and axial holes (c) on the screw plug. ) and the center hole of the separated valve seat act on the pilot valve core (5). Compression elastic force, the pilot spool (5) presses the separate valve seat (4), and is in the closed state, the pressure in the upper and lower chambers of the main spool (11) is equal (static pressure transmission), under the action of the main valve spring (10) , the main valve core is also pressed tightly on the main valve seat, the main valve port is closed, the inlet (P) and the oil return port (T) are blocked, and there is no overflow. When the pressure at the inlet (P) increases, the fluid is applied to the pilot valve. When the hydraulic pressure on the core (5) is greater than the pre-compressed elastic force on the pr...

Embodiment 2

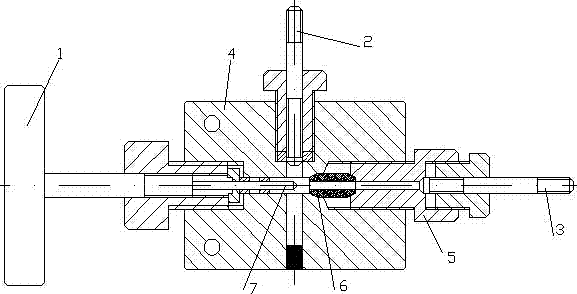

[0018] Example 2: see figure 2 Ultra-high pressure stop valve, the screw plug (5) is threadedly connected with the valve body (4), the separate valve seat (6) is pressed on the stop valve body (4) through the screw plug (5), and the handle (1) is turned , so that the valve stem pushes the valve needle (7) to press against the separate valve seat (6), thereby cutting off the incoming flow from the pipeline (3), thereby realizing the function of a stop valve, turning the handle (1) in the opposite direction to open Valve port, fluid can flow from line (3) to line (2).

[0019] The separated valve seat (4) is made of materials with high impact strength and good wear resistance. On the one hand, the strength of the valve seat can be improved and the service life of the ultra-high pressure globe valve can be extended. On the other hand, when the valve seat is worn out, only the valve seat needs to be replaced. , without replacing the entire stop valve, very suitable for ultra-hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com