Visual sensor on-site calibration device and calibration method

A visual sensor, field calibration technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of cumbersome calibration process, limited number of calibration points and accuracy, and complicated implementation, achieving simple device structure and simplified mathematical model. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

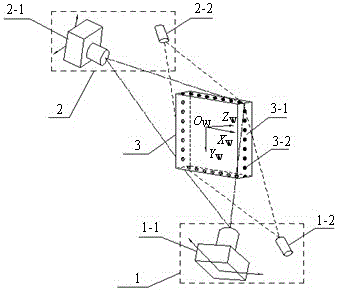

[0015] The structure and operation of the present invention are illustrated with reference to the accompanying drawings.

[0016] An on-site calibration device for a visual sensor is composed of a first structure sensor 1 , a second structure sensor 2 and a calibration target 3 .

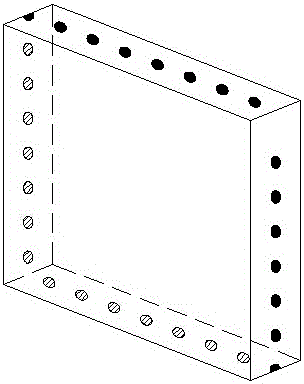

[0017] The calibration target 3 is placed at the measurement station on the measurement site, the first structure sensor 1 is placed at the lower left of the calibration target 3 , and the second structure sensor 2 is placed at the upper right of the calibration target 3 . The main structure of the calibration target 3 is a flat square target body 3-1, and several target dots 3-2 are arranged as required on the long axes of the four rectangular surfaces of the square target body 3-1. Dot 3-2 forms a measurement plane, and it is necessary to ensure that the measurement plane is at the measurement station during on-site calibration. The structure of calibration target 3 is as follows figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com