Power station boiler pressure pipeline weak leakage signal detecting method

A leakage signal and pressure pipeline technology, which can be used to detect the appearance of fluid at the leakage point, test the fluid tightness by using an electrical device, and measure the increase and deceleration rate of the fluid, etc., can solve the serious influence of experience and the detection of boiler operating conditions Problems such as poor real-time performance can avoid numerical calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

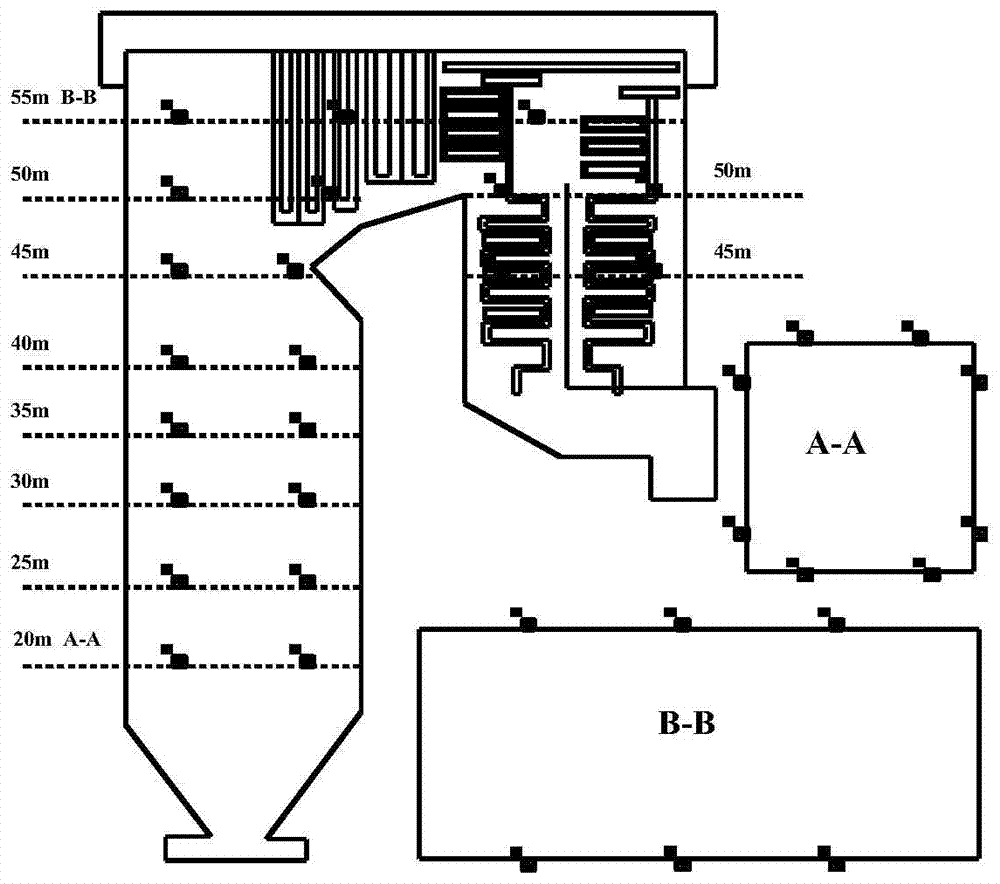

[0072] figure 2 As shown, it is an optional arrangement of acoustic sensing equipment in a 600MW utility boiler. In practical applications, the arrangement needs to be changed according to different boiler body structures.

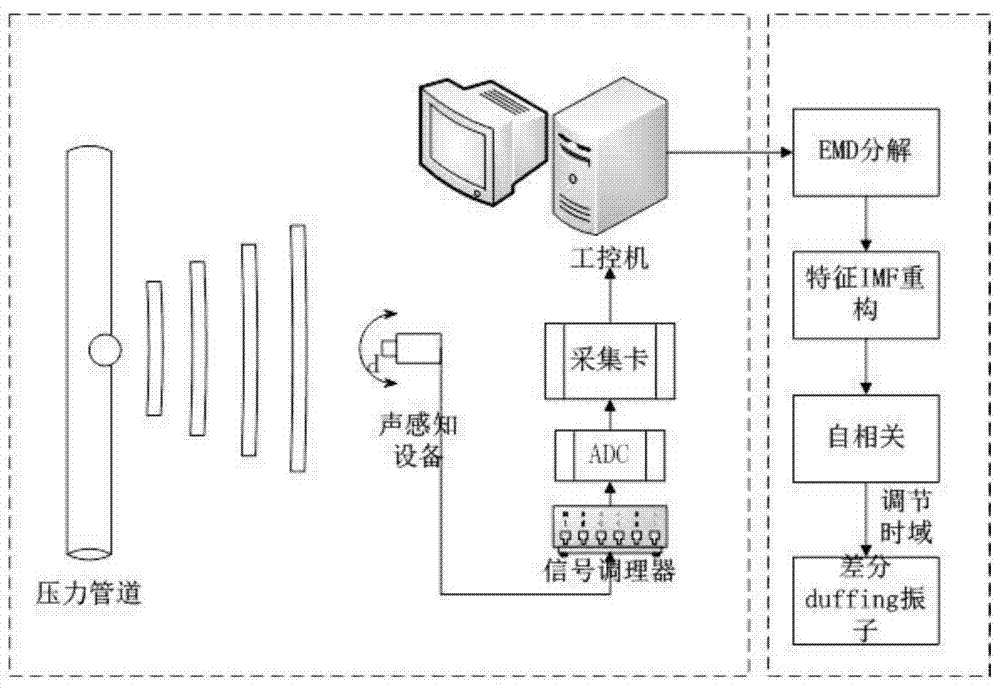

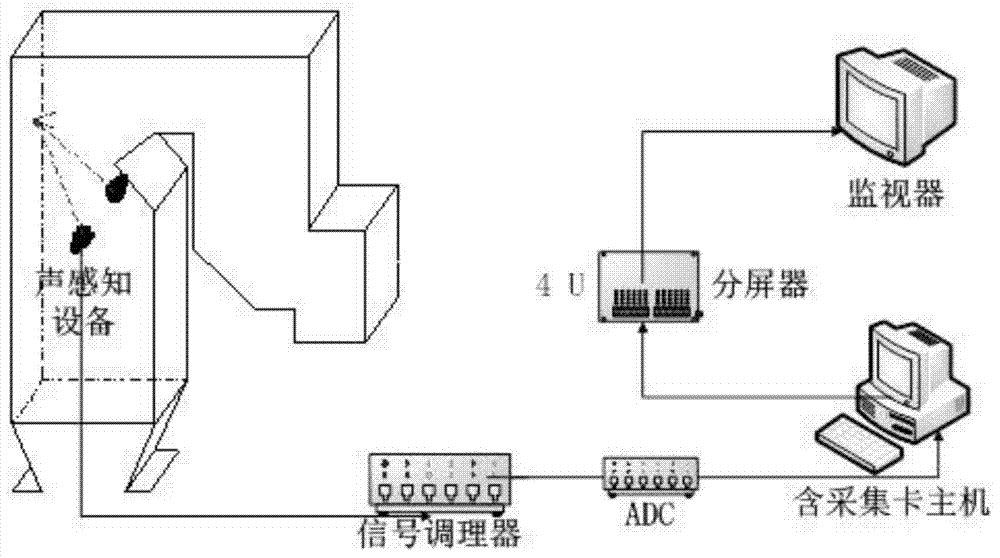

[0073] image 3 Shown is the hardware and software structure of the weak leakage signal detection system of the boiler pressure pipeline of the power station. Wherein, optionally, the acoustic perception device adopts an electret acoustic wave sensor, the sampling rate is set to 102400S / s, and the number of samples is 65536 per group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com