Method and device for testing performance of self-repairing material for well cementation

A self-healing material and a testing method technology are applied in the field of testing and testing devices for the performance of cementing self-healing materials, and can solve the problems of low success rate, failure of interlayer isolation, damage to the isolation performance of cementing cement ring, etc. The device is easy to operate and the test cycle is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

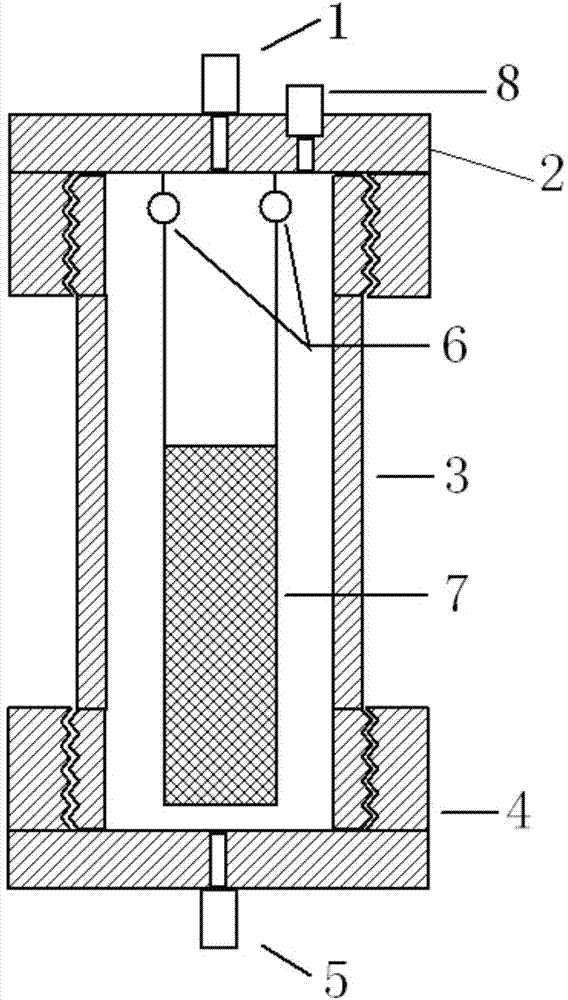

[0028] A method for testing the performance of cementing self-repairing materials under simulated gas, the sieve cylinder 7 is a cylinder, and the weight of the sieve cylinder 7 is 160g, denoted as W 1 ; The weight of sample A taken from the restoration material is 37.26g, which is recorded as W 2 The self-repairing material sample A is packed in the sieve cylinder 7, and the sieve cylinder 7 is suspended on the suspension ring 6 of the top cover of the kettle body 3, the top cover 2 is covered, the kettle body 3 is kept vertical, and the sieve cylinder 7 is suspended , respectively open outlet 1 and inlet 5, inject simulated gas through inlet 5, and discharge the air in the kettle body 3. After 10 minutes, close outlet 1, continue to inject simulated gas through inlet 5, and control the gas pressure in the kettle body 3 to 0.6Mpa , close the inlet 5, control the temperature in the kettle body 3 to 30°C, make the self-repairing material sample fully react with the simulated ga...

Embodiment 2

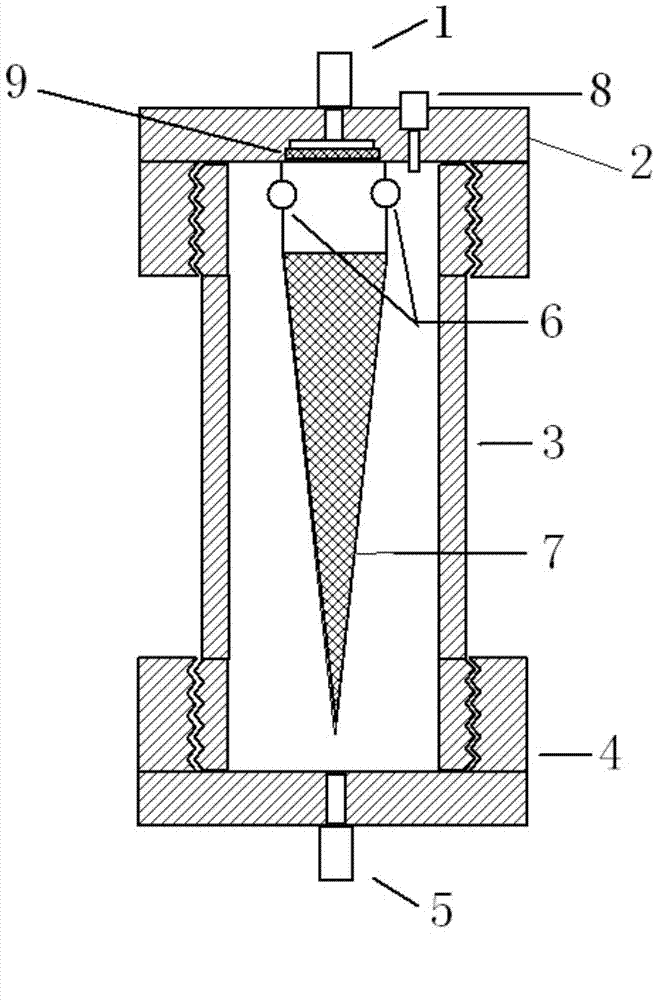

[0035] A performance test method of cementing self-repairing material under simulated liquid, the screen cylinder 7 is a cone, and the weight of the screen cylinder 7 is 110g, denoted as W 1 ; The weight taken from the restoration material sample B is 10g, denoted as W 2 The self-repairing material sample B is packed into the sieve cylinder 7; and the sieve cylinder 7 is suspended on the suspension ring 6 of the top cover of the kettle body 3, the top cover 2 is covered, the kettle body 3 is kept vertical, and the sieve cylinder 7 is suspended , control the temperature in the kettle body 3 to 30°C, open the inlet 5, and slowly inject white oil through the inlet 5 at a rate of 0.1ml / min. When the white oil flows out of the outlet 1, the reaction is complete. After standing for 24 hours, open the top cover 2. Take off the sieve cylinder 7, weigh the weight of the sieve cylinder 7 and the self-repairing material sample to be 200g, denoted as W 3 , through the formula (W 3 -W 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com