Steel rail test block

A technology of rails and test blocks, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, instruments, etc., which can solve problems such as unfavorable installation of testing equipment, vulnerability to constraints, and inconvenient rail replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

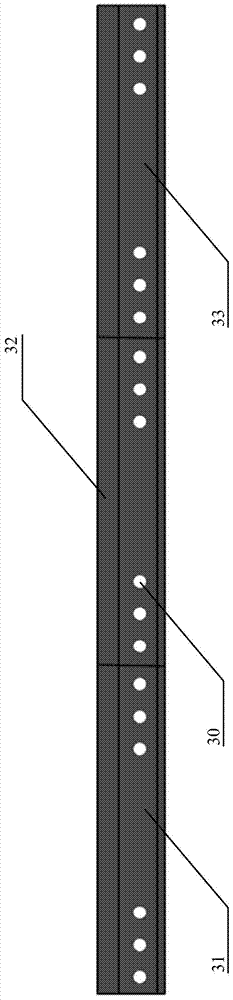

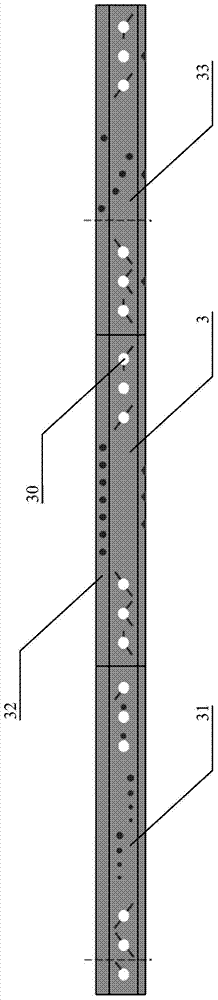

[0110] as attached figure 2 , 3 , 4, 5 and 6, the specific embodiment of the rail test block in the method of the present invention, the rail flaw detection test block is provided with bolt hole saws for simulating bolt hole cracks on the rail, for simulating rail waist position defects Any one or several kinds of damage in the rail waist transverse hole, the rail head transverse hole used to simulate the defect of the rail head part, and the rail bottom sawing used to simulate the crack of the rail bottom part form the rail test block 3 . The rail test block 3 described in the specific embodiment of the present invention can provide damage samples that are basically consistent with the dedicated line for simulating various rail damages in ultrasonic non-destructive testing, and comprehensively meet the needs of the actual situation of rail flaw detection.

[0111] The rail test block 3 includes a first test block 31, and the first test block 31 is provided with a bolt hole ...

Embodiment 2

[0180] As a preferred specific embodiment of the present invention, Embodiment 4 provides specific process parameters of the rail test block 3 . The rail test block 3 that requires ultrasonic testing includes three test blocks in total, namely the first test block 31, the second test block 32 and the third test block 33. The bolt holes shall be opened according to the standard size at the joints, and all bolt holes shall be corrugated. The rail surface of the rail is smooth, without wave wear, peeling off blocks, scratches, fish scales, welding repair layers, and uneven defects. The base metal of the rail has no obvious defects after ultrasonic testing, and there are no obvious corrosion and scars on the side and bottom of the rail. The width of the engraved groove (saw edge) of the bolt hole is 0.3-0.5mm, and the width of the engraved groove (saw edge) of the rail bottom is 0.2-0.3mm. The information mark of the test block engraved on the rail section, such as: "GTS-T1", "N...

Embodiment 3

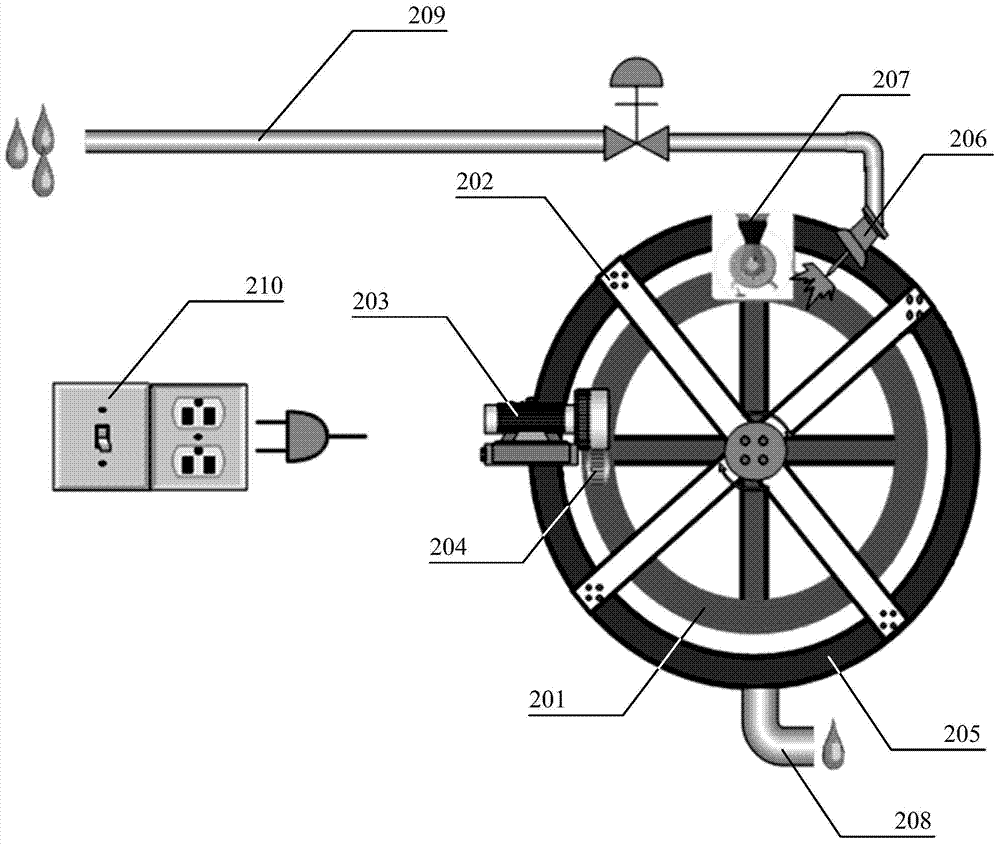

[0216] as attached Figure 13 Shown, the specific embodiment based on the rail flaw detection dynamic test device of the inventive method comprises:

[0217] A support frame 1 for carrying a flaw detection device 5, and the flaw detection device 5 is arranged on the upper part of the support frame 1;

[0218] A sliding platform 2 is movably arranged on the bottom of the supporting frame 1 along the length direction of the supporting frame 1, and the sliding platform 2 is located below the flaw detection device 5;

[0219] The rail test block 3 arranged on the sliding platform 2, the rail test block 3 is located below the flaw detection device 5, and the rail test block 3 can be driven by the sliding platform 2 along the length direction of the support frame 1, and relative to the flaw detection device 5 Moving, the rail test block 3 is used to provide various damage simulations of the rail;

[0220] The auxiliary device 4 includes a coupling water injection device 42 , and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com