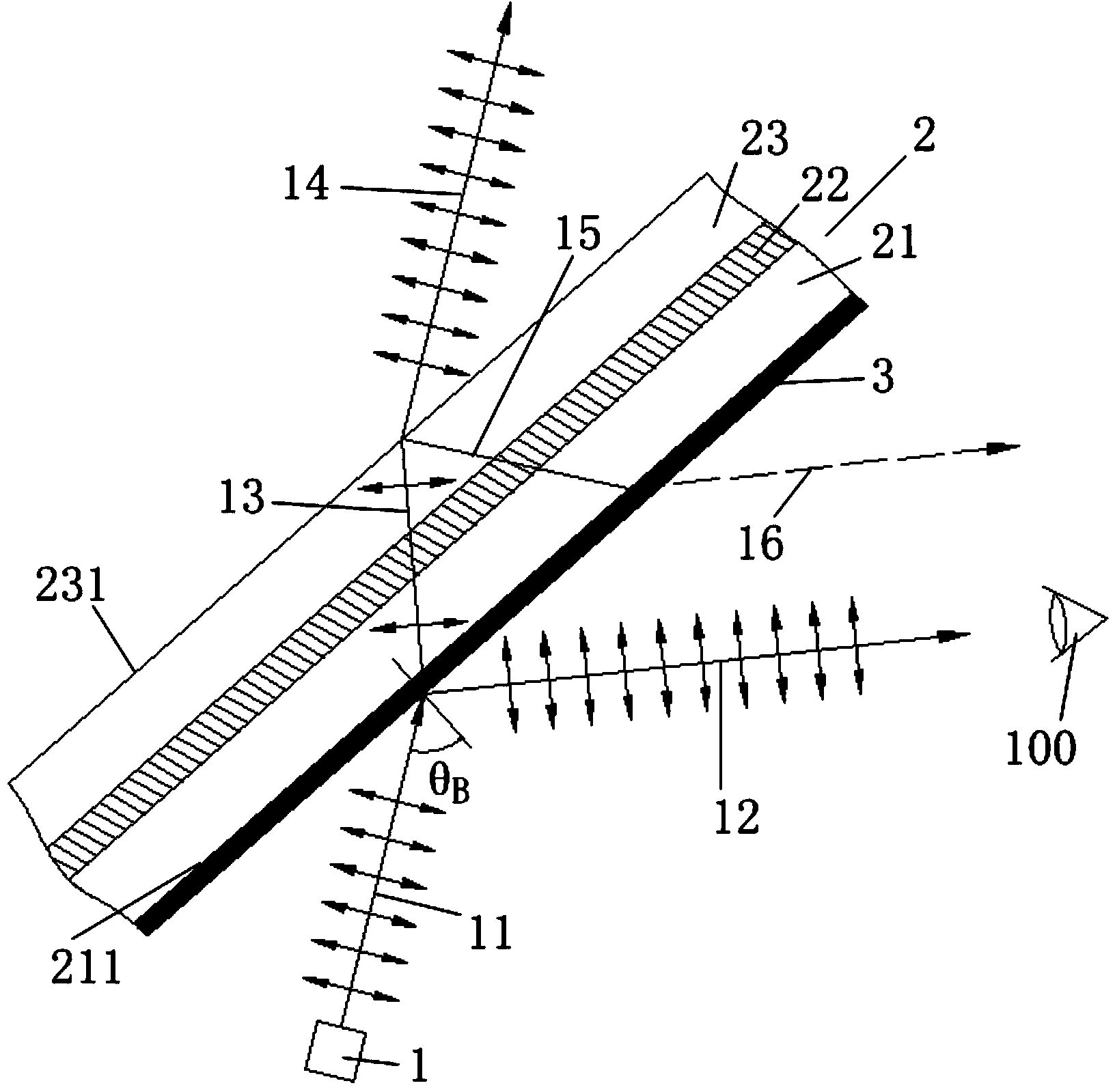

Head up display system

A head-up display system and glass plate technology, applied in the field of head-up display, can solve problems such as high process difficulty, high cost of materials and processes, ghosting, etc., and achieve the effect of simple overall structure and process, safe driving environment, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

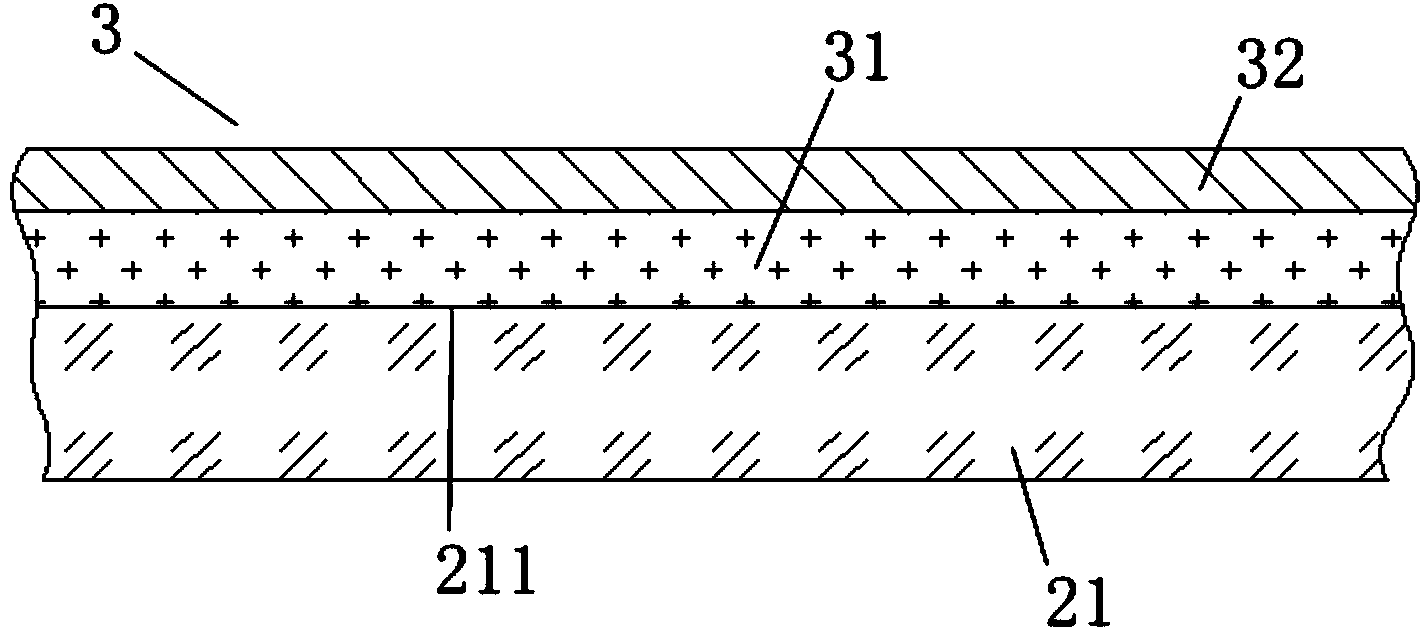

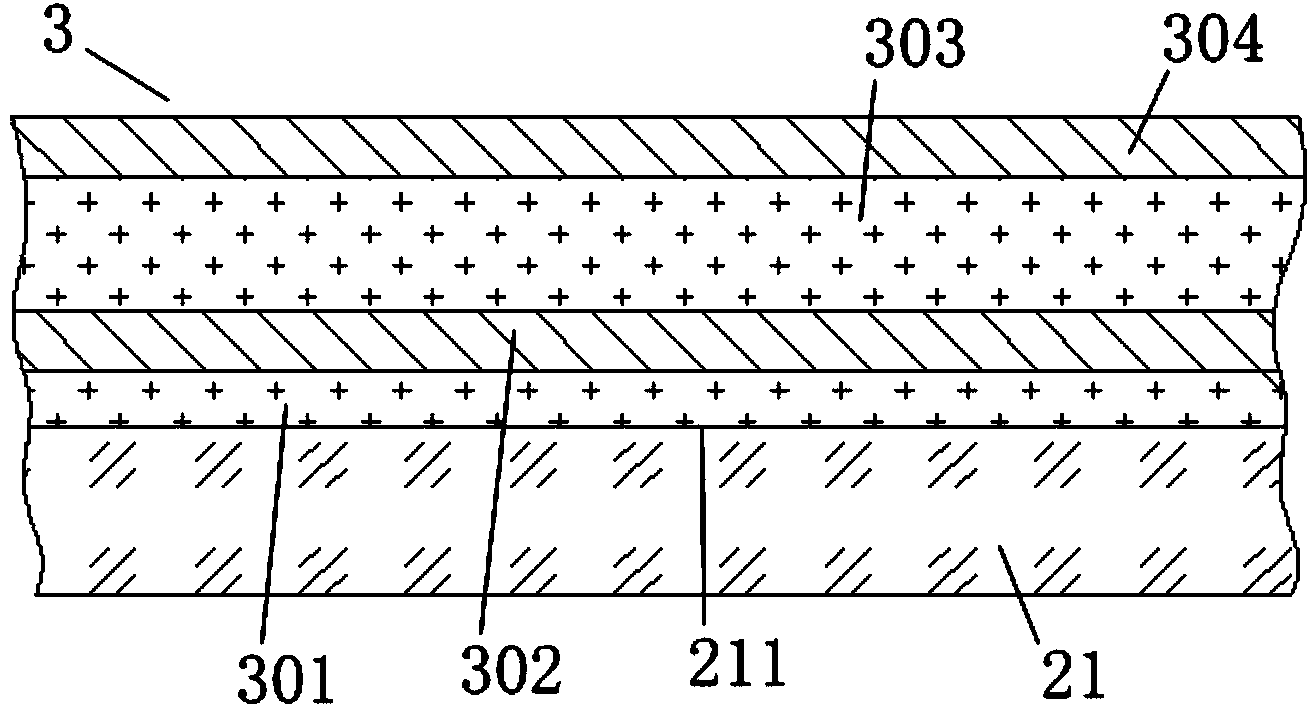

[0040] The soda lime silicate float glass with a thickness of 2.1 mm produced by Fuyao Group is used as the substrate. After cutting, edging, washing and drying, it enters the magnetron sputtering coating line for coating deposition. Alternately deposit transparent nano-film layers as shown in Table 1 on the sheet. After the film layer is deposited, the soda-lime-silicate float glass with a thickness of 2.1 mm produced by Fuyao Group is used as the matching sheet and formed according to the high-temperature molding process of automobile glass. , and sandwich a piece of colorless PVB film with a thickness of 0.76 mm in the middle, and then laminated glass with a transparent nano-film deposited after other treatments such as the installation of accessories, and the specific parameters are shown in Table 1.

[0041] Wherein, embodiment 1 is the laminated structure that transparent nanofilm comprises a high refractive index layer / low refractive index layer, and embodiment 2 is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

| Angle of incidence | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com