A dynamic positioning control system hardware-in-the-loop test simulator and its working method

A technology of control system and dynamic positioning, applied in general control system, control/adjustment system, two-dimensional position/channel control, etc., can solve the problems that the test of dynamic positioning control system cannot be realized, and avoid the danger of real ship test , Not subject to geographical restrictions, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

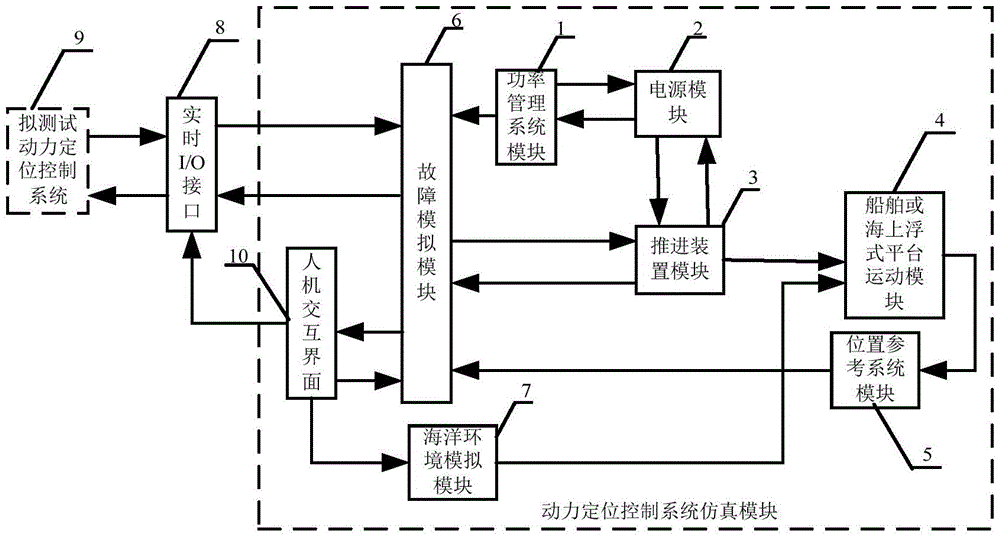

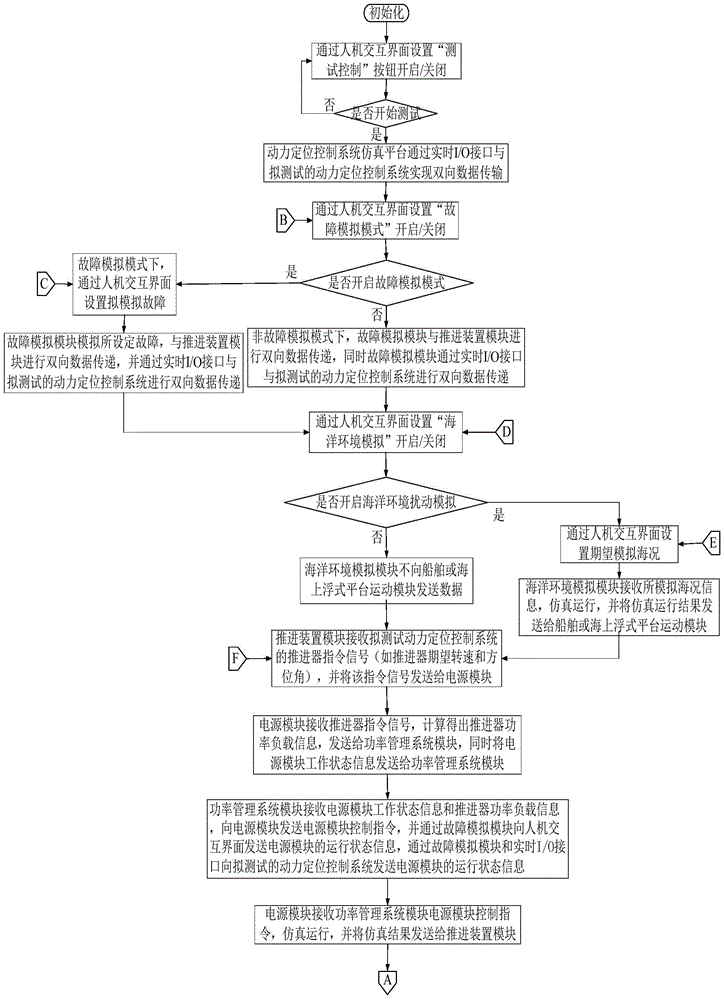

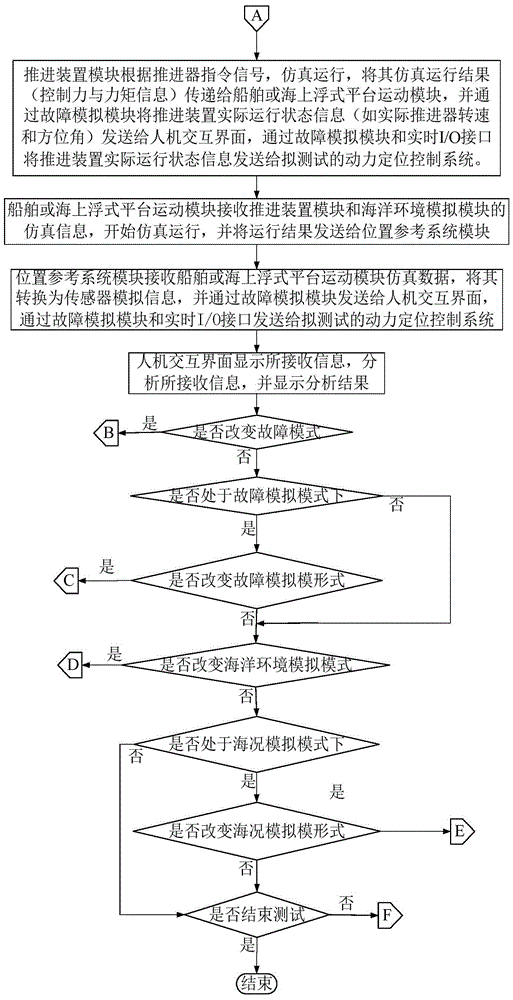

[0053] The present invention will be further described below in conjunction with the accompanying drawings. like figure 1 As shown, a dynamic positioning control system hardware-in-the-loop test simulator used in the field of ocean engineering includes a real-time I / O interface 8 and a dynamic positioning control system simulation module, and the dynamic positioning control system simulation module includes a power management system module 1. Power supply module 2, propulsion device module 3, ship or offshore floating platform movement module 4, position reference system module 5, fault simulation module 6, marine environment simulation module 7 and man-machine interface 10. The real-time I / O interface 8 is respectively connected to the dynamic positioning control system 9 and the fault simulation module 6 to be tested bidirectionally, and its other input end is connected to the output end of the man-machine interface 10; the fault simulation module 6 It is bidirectionally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com