Intelligent maintenance system for ship unloader

A technology of intelligent maintenance and ship unloader, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of unreasonable maintenance cycle, lack of users, and difficulty in understanding the equipment of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0146] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

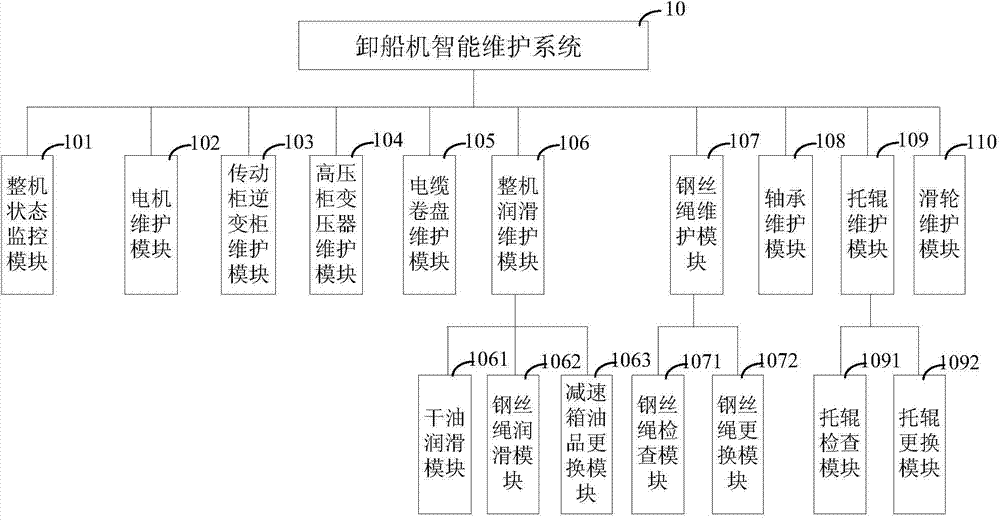

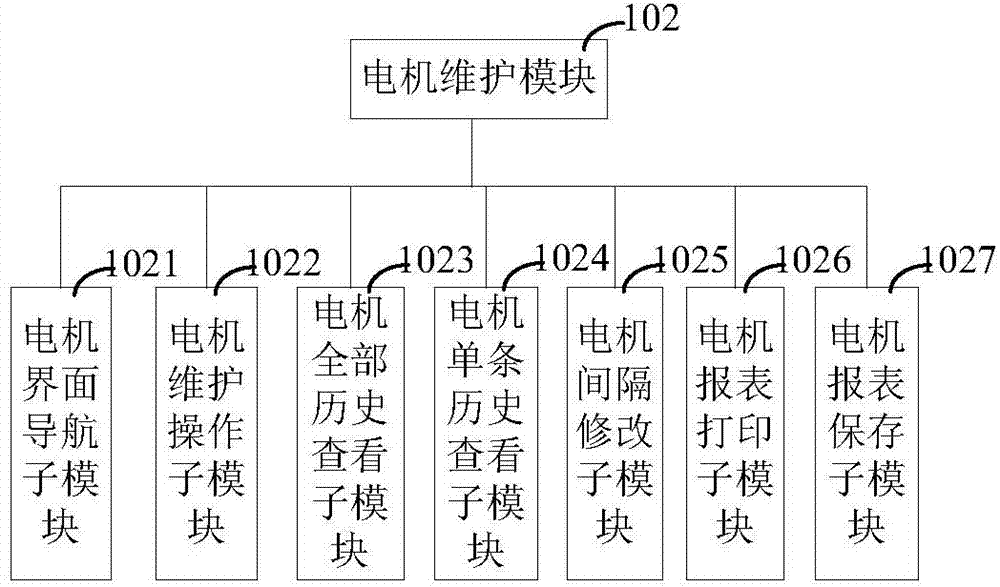

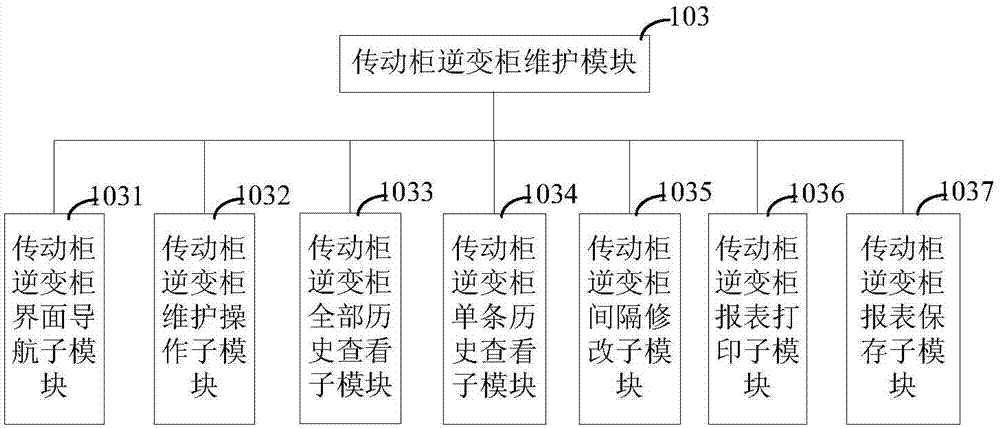

[0147] refer to figure 1 , the ship unloader intelligent maintenance system 10 of this embodiment includes a complete machine status monitoring module 101 and a maintenance management module.

[0148] Furthermore, the whole machine status monitoring module 101 monitors the operating parameters and control instructions of the ship unloader. In the process of monitoring, it can also display, warn and alarm in real time. Among them, the operating parameters can include wind speed value, lifting load, opening and closing bucket load, total load of grab bucket, load of receiving plate, total load of funnel, grabbing amount, speed of feeding belt conveyor, cumulative flow, instantaneous flow, belt speed , hoisting running time, trolley running time, cart running time and / o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com