Hot beverage foaming system containing (bi)carbonate

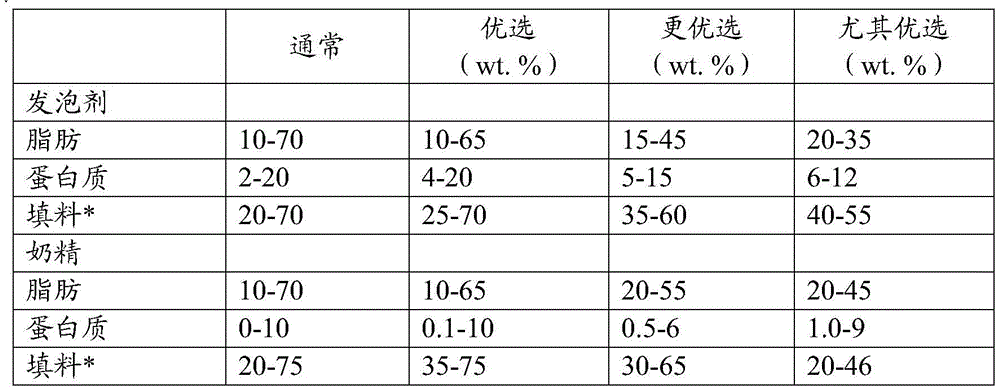

A bicarbonate and carbonate technology, used in milk replacers, coffee extraction, cocoa, etc., can solve the problems of reducing the foaming properties of creamer, pressurized gas leakage, etc., and achieve increased foam height, fine foam structure, good The effect of shelf life stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

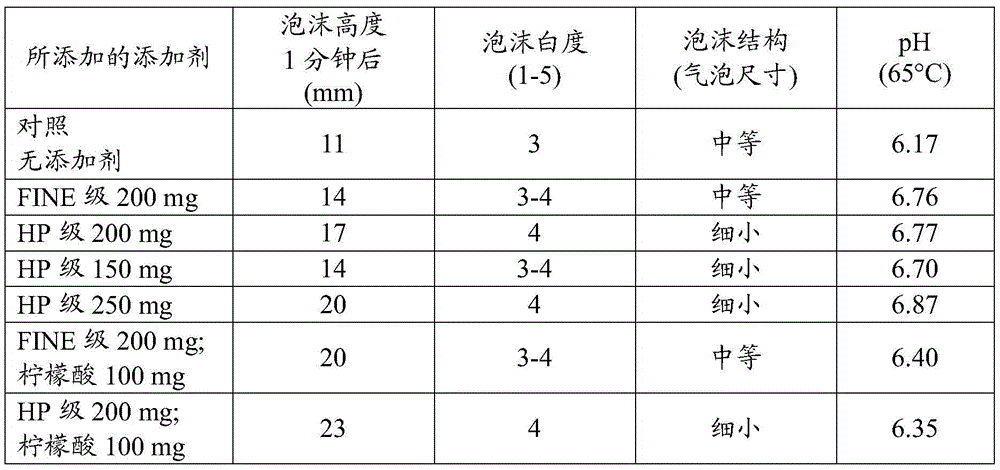

[0099] A blend of conventional instant spray-dried coffee (2 g) and foaming agent Cappa25H (8 g) was mixed with varying amounts of potassium bicarbonate, the blend containing 25 wt.% hardened coconut butter, 41 wt.% skim milk solids, 28 wt.% glucose syrup solids DE28 and <1.5 wt.% dipotassium hydrogen phosphate with a bulk density of 240 gr / L (supplier is FrieslandCampina Kievit). Potassium bicarbonate was standard quality (potassium bicarbonate FINE grade from Kudos Blends) or according to the invention (potassium bicarbonate HP grade from Kudos Blends). The HP grade was mixed with a combination of (bi)carbonate and amphiphilic substances. Comparison was made with a mixture without any added bicarbonate (control). The effect of an additional food acid (citric acid) was also evaluated. Taste evaluations were also performed on all samples. No taste bias was observed for any of the samples.

[0100]

[0101] Color: Use a scale of 1 to 5, in order from less white to whiter...

Embodiment 2

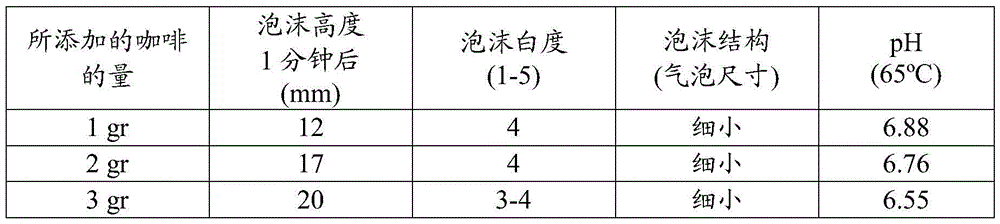

[0105] The following examples in the table describe the effect of coffee volume and associated acidity profile after reconstitution of hot beverage mixes containing subsequent coffee volume variations, 8 grams of foaming agent Cappa 25H and 200 mg of HP grade bicarbonate. The effect of the composition of the hot beverage mix can be clearly observed. More specifically, the amount of components with acidic character affects foam height and foam appearance.

[0106]

[0107] The above formulation was produced on a large scale under factory conditions, and the results of the preliminary accelerated shelf life test (preliminary accelerated shelf life) showed excellent properties similar to those described in the previous examples. This also demonstrates the fact that the bicarbonate used according to the invention provides protection against humidity or other factors which, in the absence of an amphiphilic substance combined with the bicarbonate, would spoil the final beverage m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com