Odor-resistant and sun-proof fine smooth and soft plus material

A kind of fabric and delicate technology, applied in the field of textile fabrics and fabrics, can solve the problems of insufficient light fastness, waste, easy to produce peculiar smell, etc., and achieve good acid resistance, alkali resistance, light resistance, good UV blocking, and high initial modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

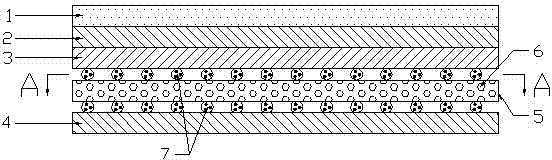

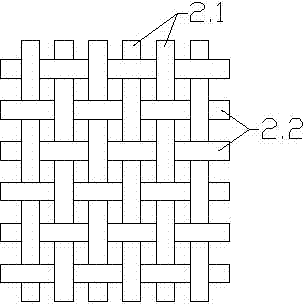

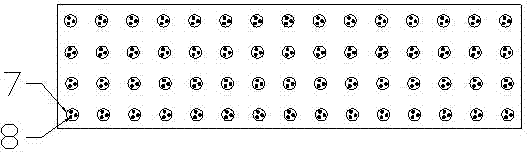

[0027] see Figure 1-3 , the present invention relates to a deodorant, sunscreen fine and soft fabric, which comprises a sunscreen layer 1, a fiber layer 2, a woven fabric layer 3, a polyurethane film layer 5 and a knitted fabric layer 4 from the outside to the inside, the sunscreen layer 1 and the knitted fabric layer The fiber layer 2, the fiber layer 2 and the woven fabric layer 3 are woven and connected to each other. The sun protection layer 1 is the outermost layer. It is polypropylene, which includes polypropylene warp yarn 2.1 and polypropylene weft yarn 2.2. The polypropylene warp yarn 2.1 and polypropylene weft yarn 2.2 are interlaced and tightly woven, and the polypropylene fiber itself is light in texture, high in strength, large in elongation, high in initial modulus, and excellent in elasticity. It hardly absorbs moisture, and polypropylene also has good acid and alkali resistance and light resistance.

[0028] The polyurethane film layer 5 contains micropores 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com