Fullerene composite fiber fabric and preparation method thereof

A composite fiber fabric and a technology for fiber fabrics, applied in the field of fiber fabrics, can solve the problems of difficulty in uniform dispersion, poor adsorption force, complicated steps, etc., and achieve the effects of antibacterial and multifunctional properties, good bonding, and good UV protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A kind of fullerene composite fiber fabric and its preparation method

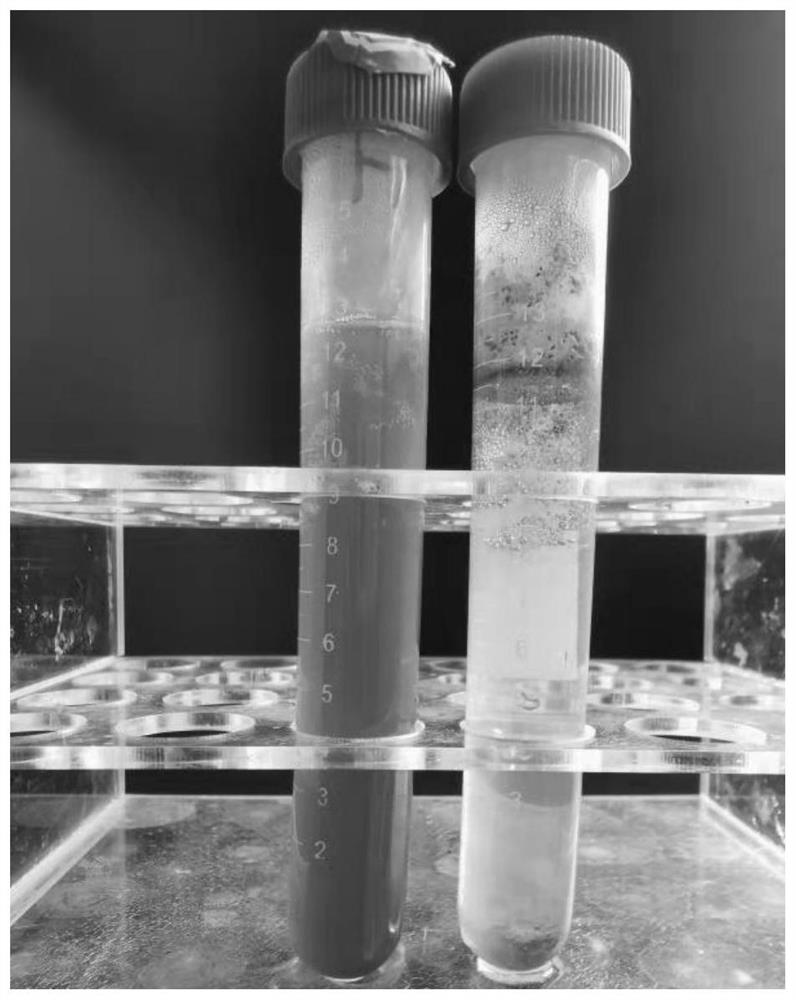

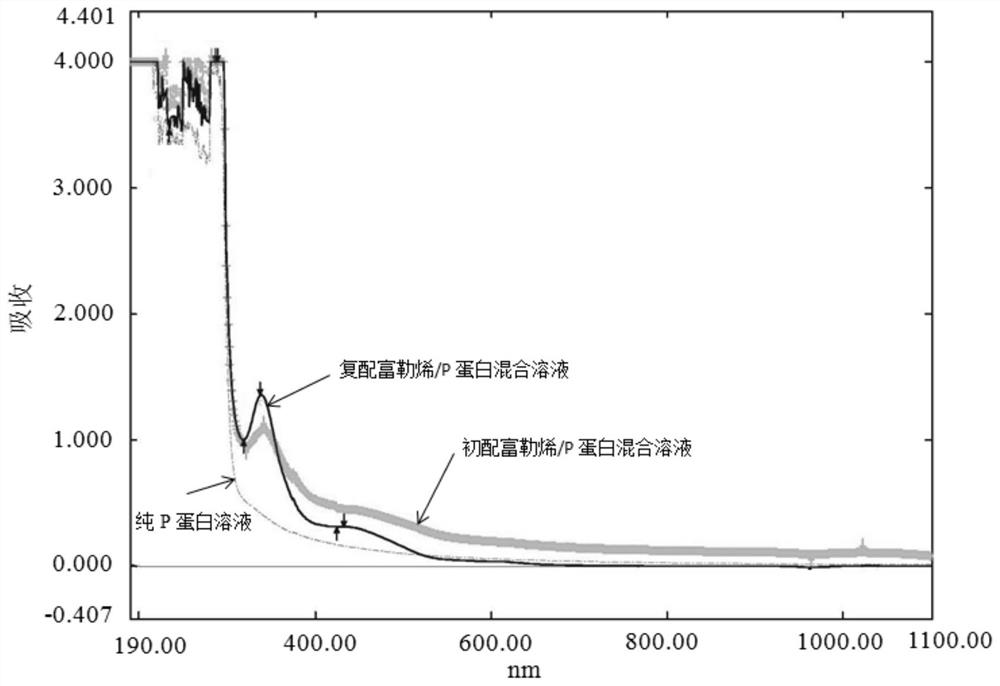

[0047] S1, the fullerene of 0.1 weight part is added in the test tube that fills 100 weight part of high-purity water and stirs and mixes evenly (the picture of gained solution sees figure 1 In the test tube on the right side, the black substance floating on the upper surface of the solution is fullerene, which shows that the fullerene is basically not dissolved in water), then add 0.3 parts by weight of P protein solution, stir it evenly by magnetic force, ultrasonically disperse for 30min, and centrifuge the resulting mixture , the centrifugation temperature is controlled at 4°C, the rotational speed is controlled at 11,000 rpm, and the centrifugation time is controlled at 20 minutes. The centrifuged supernatant obtained is the fullerene / P protein mixed solution, and the fullerene in the fullerene / P protein mixed solution is The average particle size is 172.4nm, the picture of the fu...

Embodiment 2

[0050] Embodiment 2: A kind of fullerene composite fiber fabric and its preparation method

[0051] S1. Add 0.1 parts by weight of fullerene to 100 parts by weight of high-purity water, then add 0.5 parts by weight of P protein solution, stir evenly with magnetic force, disperse ultrasonically for 30 minutes, and centrifuge the resulting mixture. At 11,000 rpm, the centrifugation time was controlled at 20 minutes, and the centrifuged supernatant obtained was the fullerene / P protein mixed solution.

[0052] S2. Rinse the fiber fabric (60mm×50mm) in high-purity water for 10 minutes, rinse in carbonate buffer solution for 10 minutes, soak in fullerene / P protein mixed solution for 30 minutes, and rinse in high-purity water 3 times (each 10 minutes), and then dried at 70°C for 2 hours to obtain a modified fiber fabric;

[0053] S3. Repeat the treatment of the modified fiber fabric by the method of step S2 5 times to obtain a fullerene composite fiber fabric (FX-2). According to S...

Embodiment 3

[0054] Embodiment 3: A kind of fullerene composite fiber fabric and its preparation method

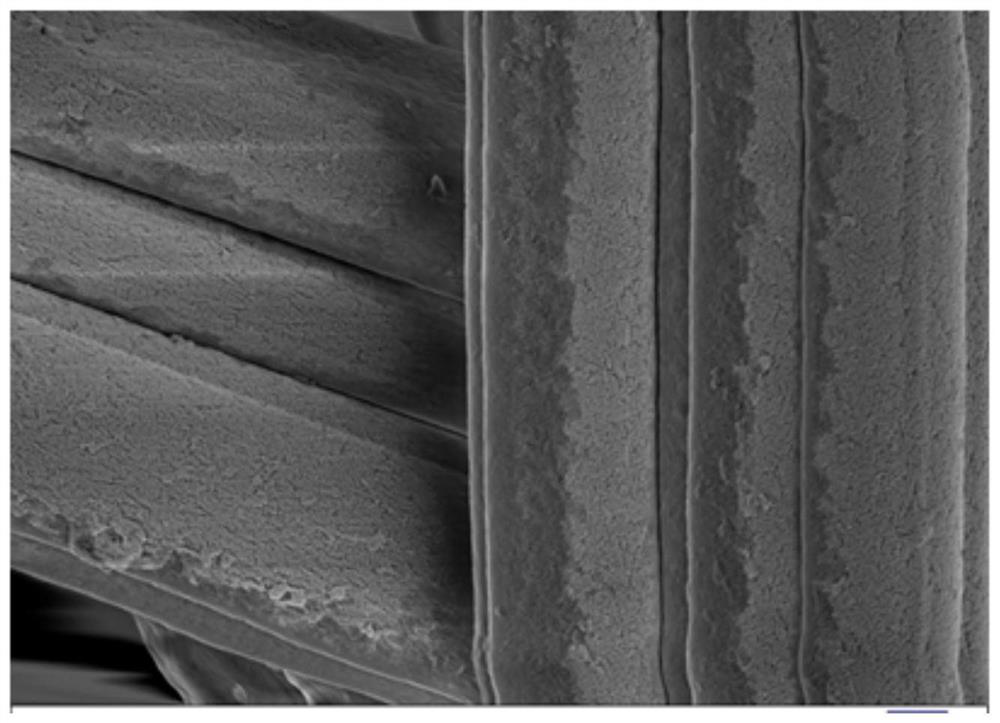

[0055] The fullerene composite fiber fabric is prepared according to the method of Example 1, the difference is that step S2 does not include the step of soaking in the PEI solution, and all the other steps and conditions are the same as in Example 1 to obtain the fullerene composite fiber fabric (FX -3). The SEM results of the fullerene composite fiber fabric FX-3 are as follows: Figure 6 shown. From Figure 6 It can be seen that the surface of the fullerene composite fiber fabric is relatively rough, and there is no scale-like attachment, and a small amount of coating is evenly attached to the fiber surface, and the single fiber is relatively small. image 3 smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com