Solid ultrasonic coupling agent and preparation method thereof

An ultrasonic couplant and couplant technology, applied in echo/ultrasonic imaging agent and other directions, can solve the problems of complicated design and use of focused ultrasound device, electrical safety hazards and inconvenience of focused ultrasound transmitting device, and achieve convenient storage and use. And economical, good ultrasonic conduction effect, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

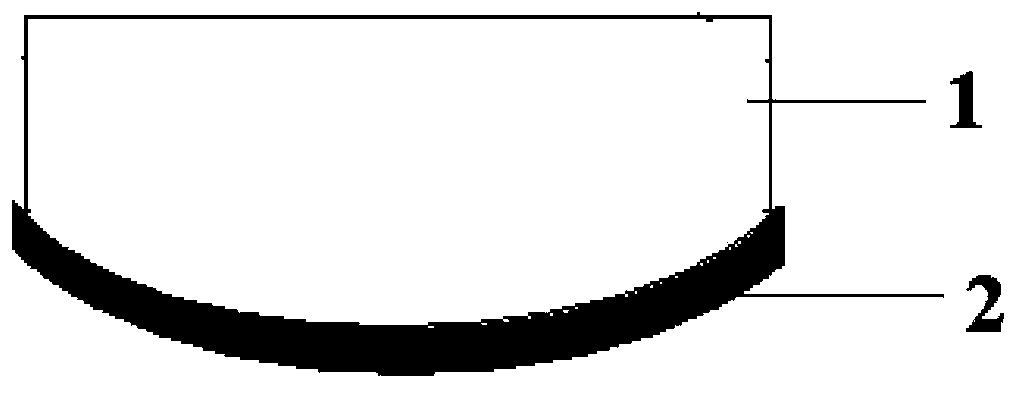

Image

Examples

Embodiment 1

[0056] The deacetylation degree is 89%, the viscosity is 700mPa·s, and the flaky food-grade chitosan is dissolved in 4% acetic acid aqueous solution to obtain 6% chitosan acetic acid aqueous solution. The temperature of the whole dissolution process is controlled at about 40°C. The aqueous solution of chitosan acetic acid was placed under vacuum conditions at a temperature of 40° C. and -0.09 Mpa for 36 hours to fully defoam. Then, the degassed chitosan acetic acid aqueous solution is poured into the forming mold. Fully immerse the poured molding mold in the curing solution for 36 hours. The solidification solution is a 2% sodium hydroxide solution, which is added with ethanol of 1 / 10 volume of the sodium hydroxide solution, and the temperature is about 10 °C. Pour out the cured coupling agent from the mold, soak it in clean water, and change the water once every 2 hours of soaking. Obtain chitosan solid coupling agent. The chitosan solid-state coupling agent is flexible a...

Embodiment 2

[0058] The degree of deacetylation is 86%, the viscosity is 820mPa·s, and the powdery food-grade chitosan with a particle size of 80 meshes is used as the raw material and dissolved in a 2.5% acetic acid aqueous solution to obtain a 4% chitosan acetic acid aqueous solution. The temperature of the whole dissolution process is controlled at about 20°C. The chitosan acetic acid aqueous solution was placed under vacuum conditions at a temperature of 25° C. and -0.09 Mpa for 36 hours to fully deaerate. Then, the degassed chitosan acetic acid aqueous solution is poured into the forming mold. Fully immerse the poured molding mold in the curing solution for 12 hours. The solidification solution is a 6% sodium hydroxide solution, which is added with ethanol of 1 / 20 the volume of the sodium hydroxide solution, and the temperature is about 25 °C. Pour out the cured coupling agent from the mold, soak it in clean water, and change the water once every 2 hours of soaking. Obtain chitosan...

Embodiment 3

[0060] The degree of deacetylation is 82%, the viscosity is 960mPa·s, and the powdery food-grade chitosan with a particle size of 120 meshes is used as the raw material to dissolve in a 1% acetic acid aqueous solution to obtain a 2% chitosan acetic acid aqueous solution. The temperature of the whole dissolution process is controlled at about 10°C. The aqueous solution of chitosan acetic acid was placed under vacuum conditions at a temperature of 10° C. and -0.09 Mpa for 36 hours to fully defoam. Then, the degassed chitosan acetic acid aqueous solution is poured into the forming mold. Fully immerse the poured molding mold in the curing solution for 24 hours. The solidification solution is a 10% sodium hydroxide solution, which is added with ethanol of 1 / 30 of the volume of the sodium hydroxide solution, and the temperature is about 40 °C. Pour out the cured coupling agent from the mold, soak it in clean water, and change the water once every 2 hours of soaking. Obtain chitos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com