Swirler

A vortex device and vortex chamber technology, applied in the field of vortex devices, can solve the problems of high noise, inability to separate oil fume, dust particle pollution, etc., and achieve the effect of reducing construction cost and operating cost, improving equipment operating efficiency, and realizing chemical reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

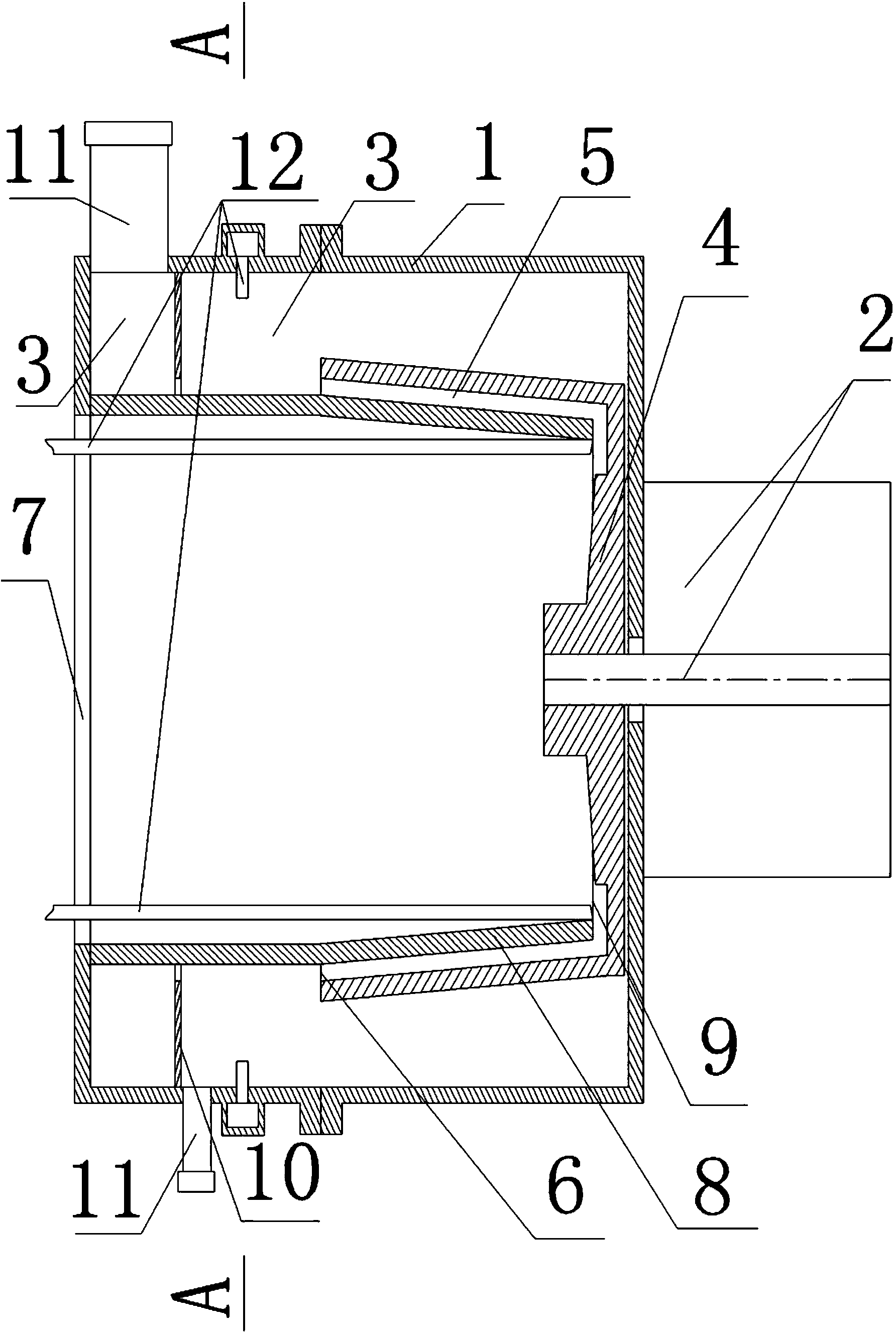

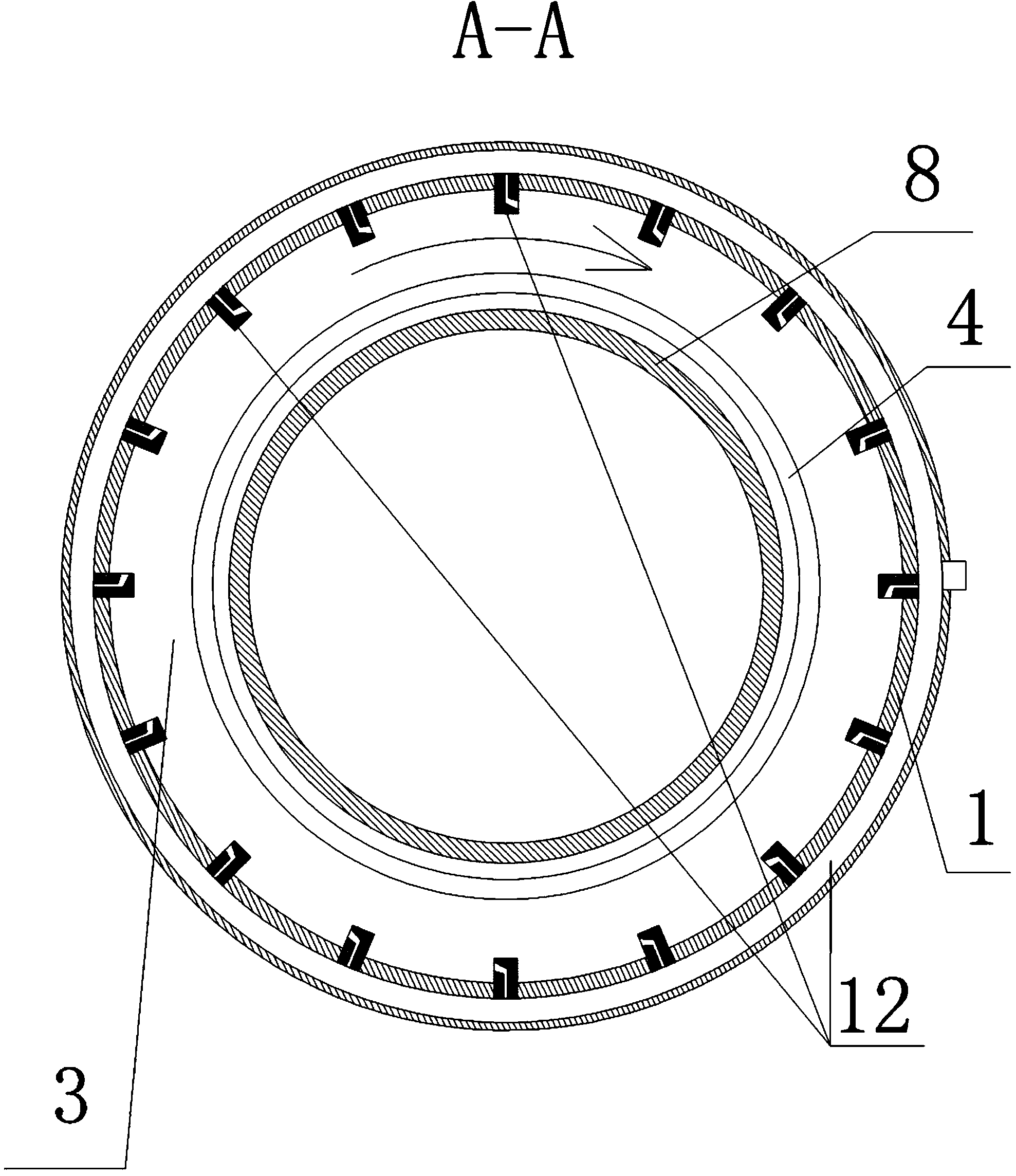

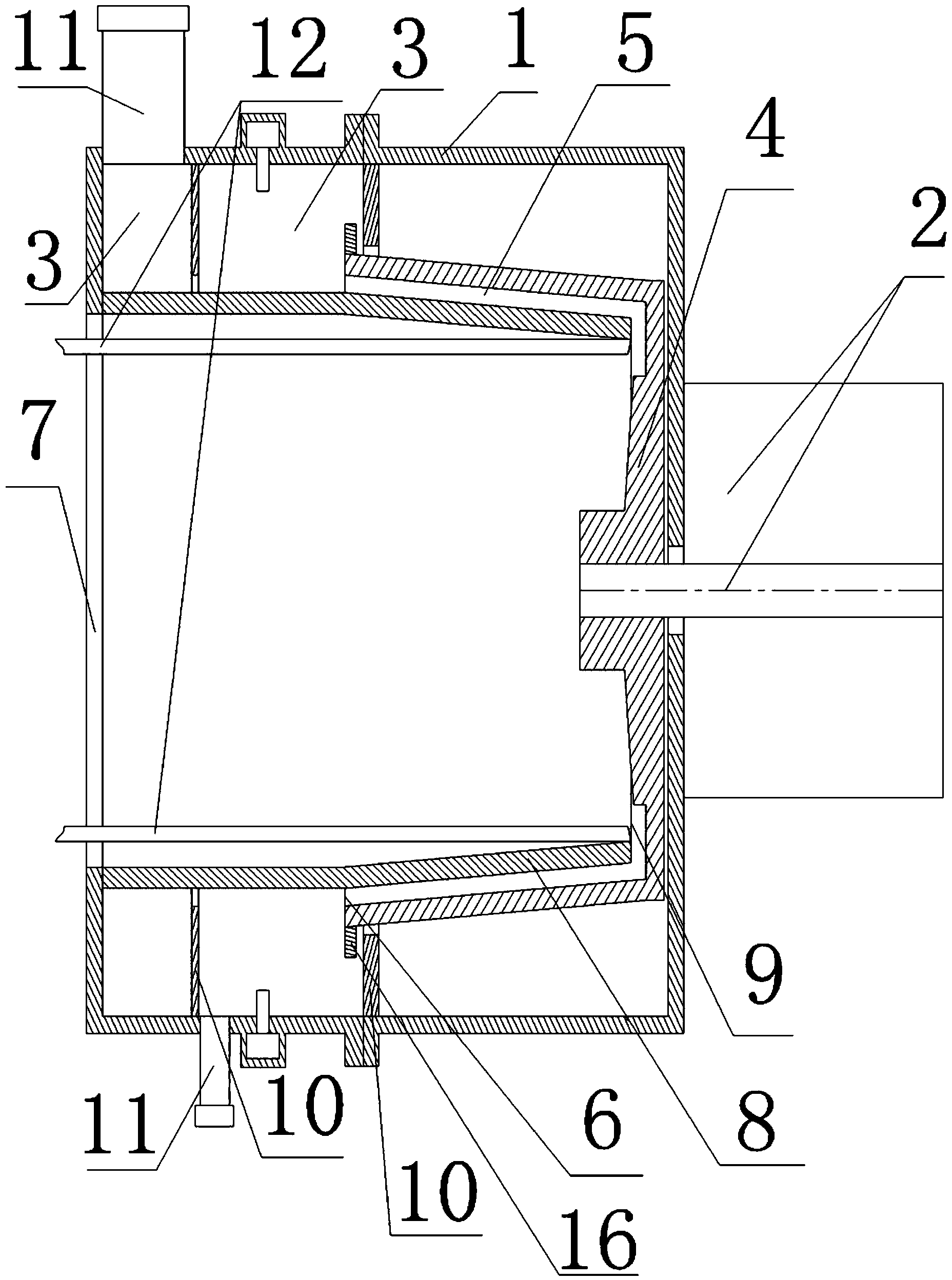

[0040] The main structure of the vortex generator of the present invention includes a housing 1 and a transmission device 2, the transmission device 2 is arranged on the housing 1, the housing chamber 3 is arranged in the housing 1, the vortex wheel 4 is arranged in the housing chamber 3, the transmission device 2 and the vortex wheel 4 connection, the vortex wheel 4 is provided with a vortex chamber 5, one end of the vortex chamber 5 is provided with a vortex chamber outlet 6, and the housing 1 is provided with a housing cavity inlet 7 corresponding to the vortex chamber outlet 6, and the housing cavity inlet 7 is connected to a guide tube 8, and the guide tube 8 penetrates into the vortex chamber 5 through the outlet 6 of the vortex chamber, the outlet 9 of the guide tube penetrates into the vortex chamber 5, at least one surrounding partition 10 is arranged on the inner wall of the casing cavity 3, and at least two discharge ports 11 are arranged on the casing cavity 3 A liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com