Steel plate with thickness of smaller than 60mm and yield strength of 690MPa and preparation method of steel plate

A yield strength, steel plate technology, applied in the field of steel, can solve the problems of complex heat treatment process, high alloy cost, complex production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

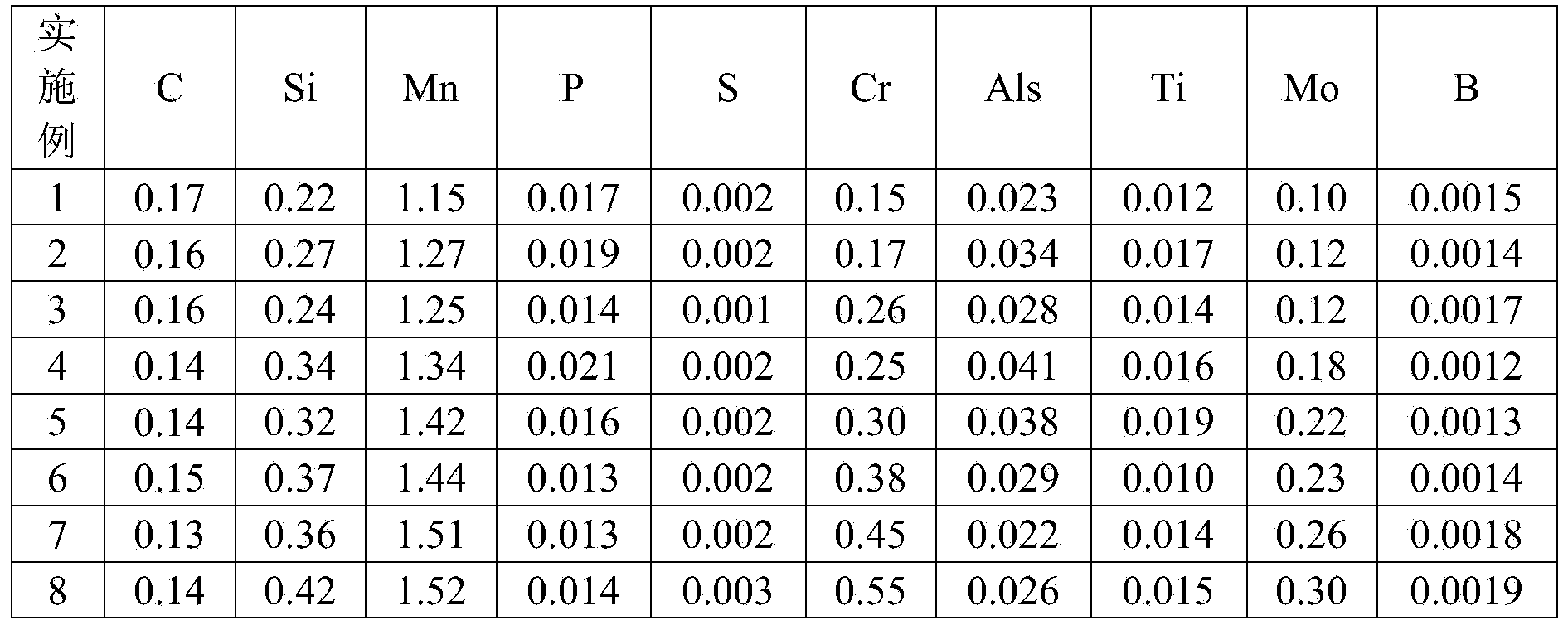

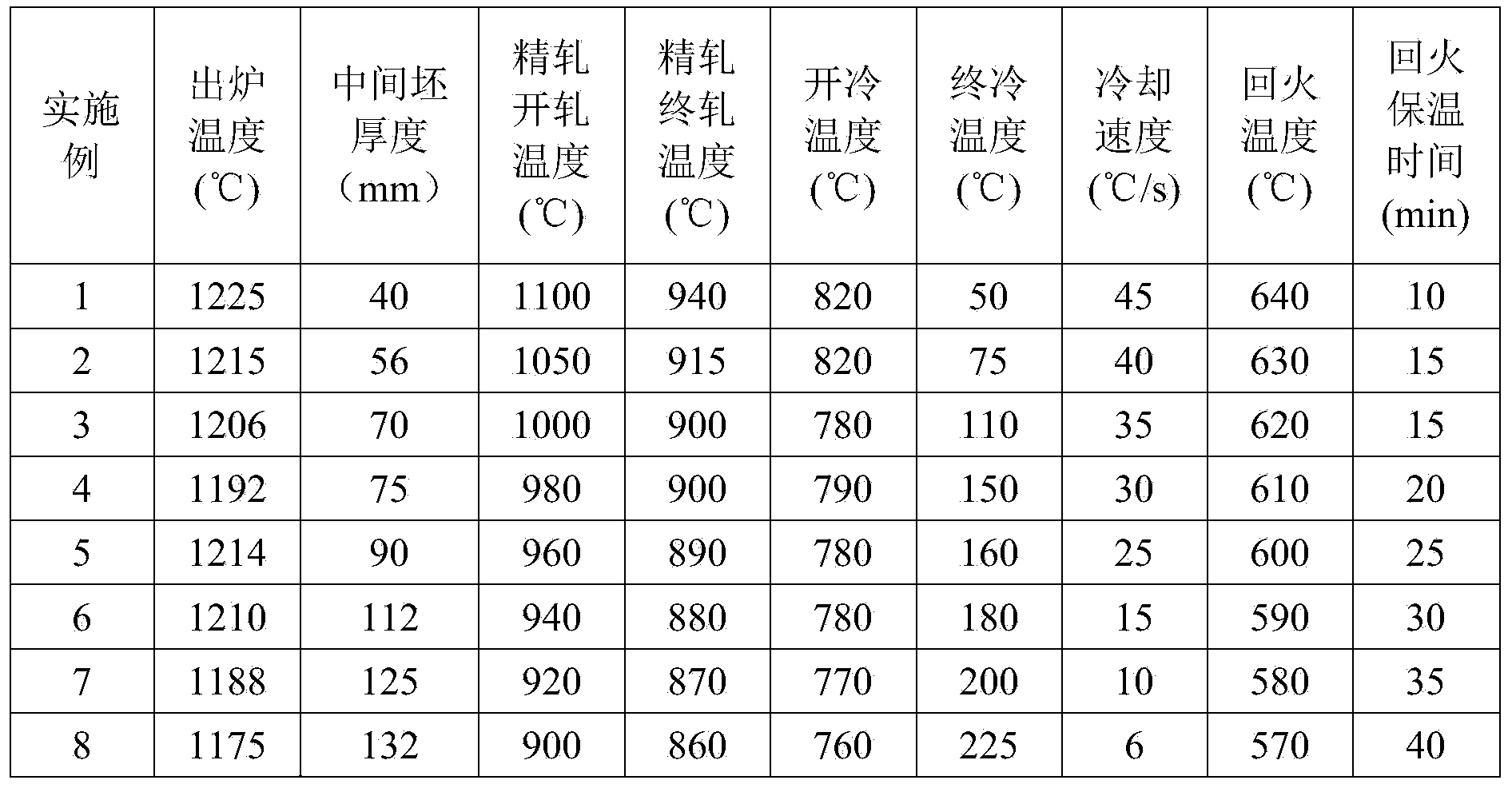

[0050] The chemical composition of the high-strength steel plate with a thickness of 60 mm or less and a yield strength of 690 MPa grade involved in the present invention is smelted in a converter according to the chemical composition shown in Table 1 and cast into continuous casting slabs or ingots, and the continuous casting slabs or ingots are opened in a heating furnace Heating, using a medium plate rolling mill or a steel coil rolling mill, and the rolled steel plate is only subjected to one off-line tempering heat treatment. See Table 2 for main process parameters such as slab discharge temperature, final rolling temperature, and final cooling temperature. The tensile properties of the corresponding steel plates, longitudinal impact energy at -20°C, and thickness specifications are listed in Table 3. It can be seen that the steel of the present invention has excellent low-temperature impact toughness, and the longitudinal AKv at -20°C is not less than 150J. figure 1 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com