False-twisting device and process method for single-spindle disc-type ring spinning

A process method and false twisting technology, applied in the direction of textiles and papermaking, etc., can solve the problems of enlarging arc, increasing the actual length of spinning section, difficulty in threading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

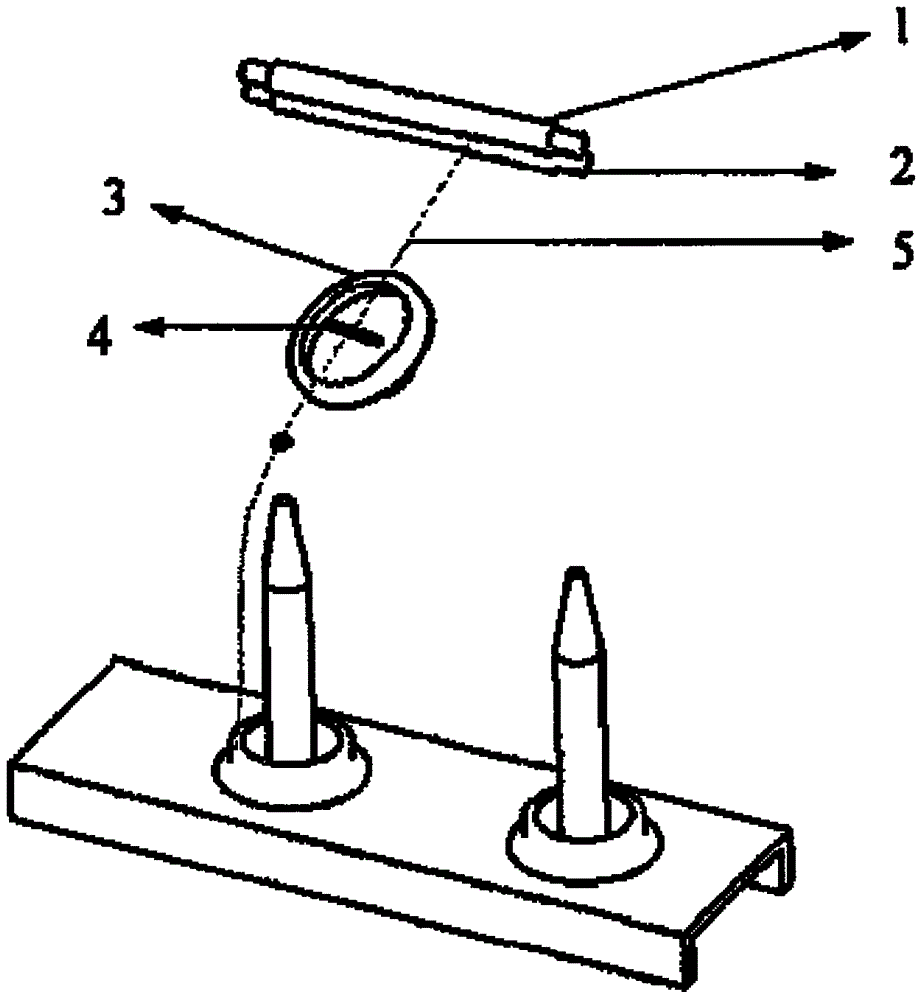

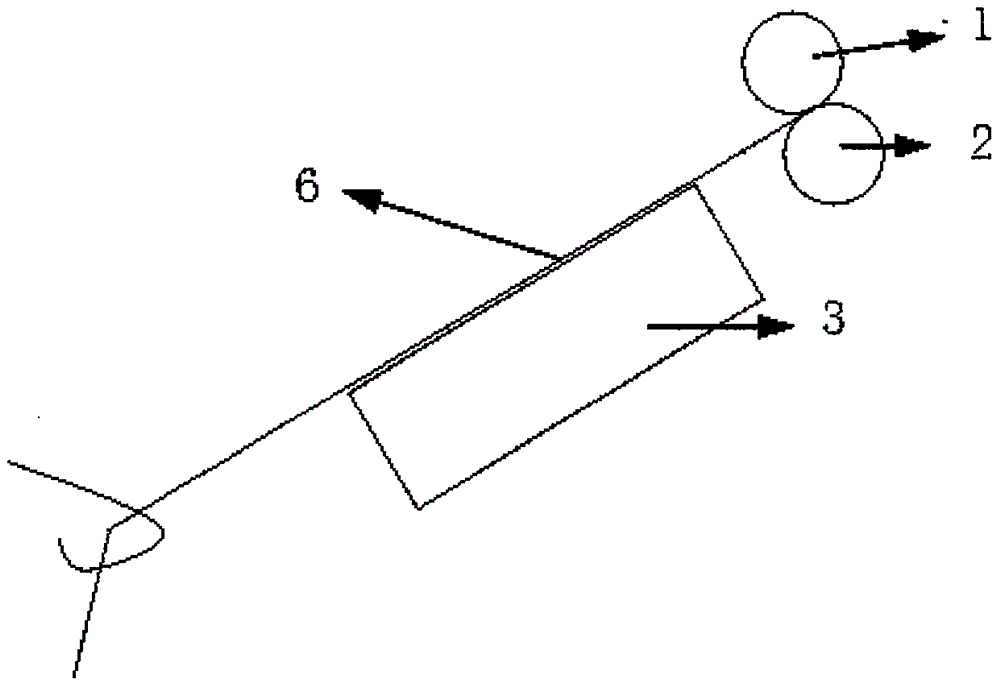

[0026] figure 1 and figure 2 They are the three-dimensional schematic diagram of the spinning device, and the geometric relationship diagram between the spinning section and the false twist disc. Such as figure 1 , 2 As shown, the fiber bundle 5 output by the front nip of the drafting system composed of the front roller 2 and the front rubber roller 1 passes through the upper side of the false twisting disc 3, and then under the action of the separation rod 4, the false twisting disc 3 The spinning section is closely combined with the upper side and the lower side of the false twisting disc 3, and the false twisting disc rotating at high speed performs false twisting on the spinning section.

Embodiment approach 2

[0028] figure 1 and figure 2 They are the three-dimensional schematic diagram of the spinning device, and the geometric relationship diagram between the spinning section and the false twist disc 3, respectively. Put a circular rubber ring on the false twisting disc 3, the fiber bundle 5 output by the front nip of the drafting system composed of the front roller 2 and the front rubber roller 1 passes through the upper side of the rubber ring of the false twisting disc 3, Then under the action of the spacer bar 4, the false twist disc spinning segment 6 is closely combined with the rubber ring upper and lower sides of the false twist disc 3, and the false twist disc 3 rotating at high speed performs false twisting to the spinning segment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com