Basement roof greening slope filling method

A roof and slope technology, applied in fill, artificial islands, underwater structures, etc., can solve problems such as limiting the space for garden design to achieve the effect of avoiding damage and improving the stress of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The slope method of greening on the roof of the basement includes:

[0032] In step a, the drainage of the roof of the basement is done well. In this embodiment, the organization network trench is used to realize the drainage of the roof of the basement.

[0033] While completing the drainage construction of the basement roof, carry out foundation positioning construction for the structures required to be built on the base of the roof, carry out positioning and lofting of the super-loaded and super-high backfill area, delineate the EPS board backfill area, and record the backfill elevation and requirements at the same time.

[0034] In step b, draw the corners of the EPS board backfill area, and use half-brick masonry to fix the corners. Generally, the length of both sides is 750mm, and the height is only three bricks, so that the EPS board will not slip during construction.

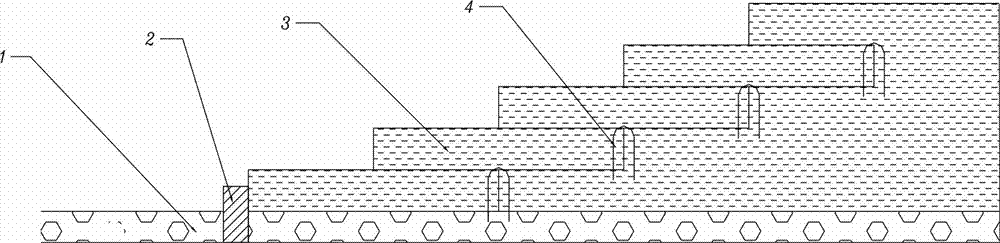

[0035] Step c, carry out EPS pile slope, figure 1 It is a structural schematic diagram of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com