Pipe joint for heat exchanger

A technology for heat exchangers and pipe joints, which is applied in the field of pipe joints, can solve problems such as thermal deformation, and achieve the effects of less thermal deformation and less strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate a specific embodiment of the present invention, but are not intended to limit the scope of the present invention.

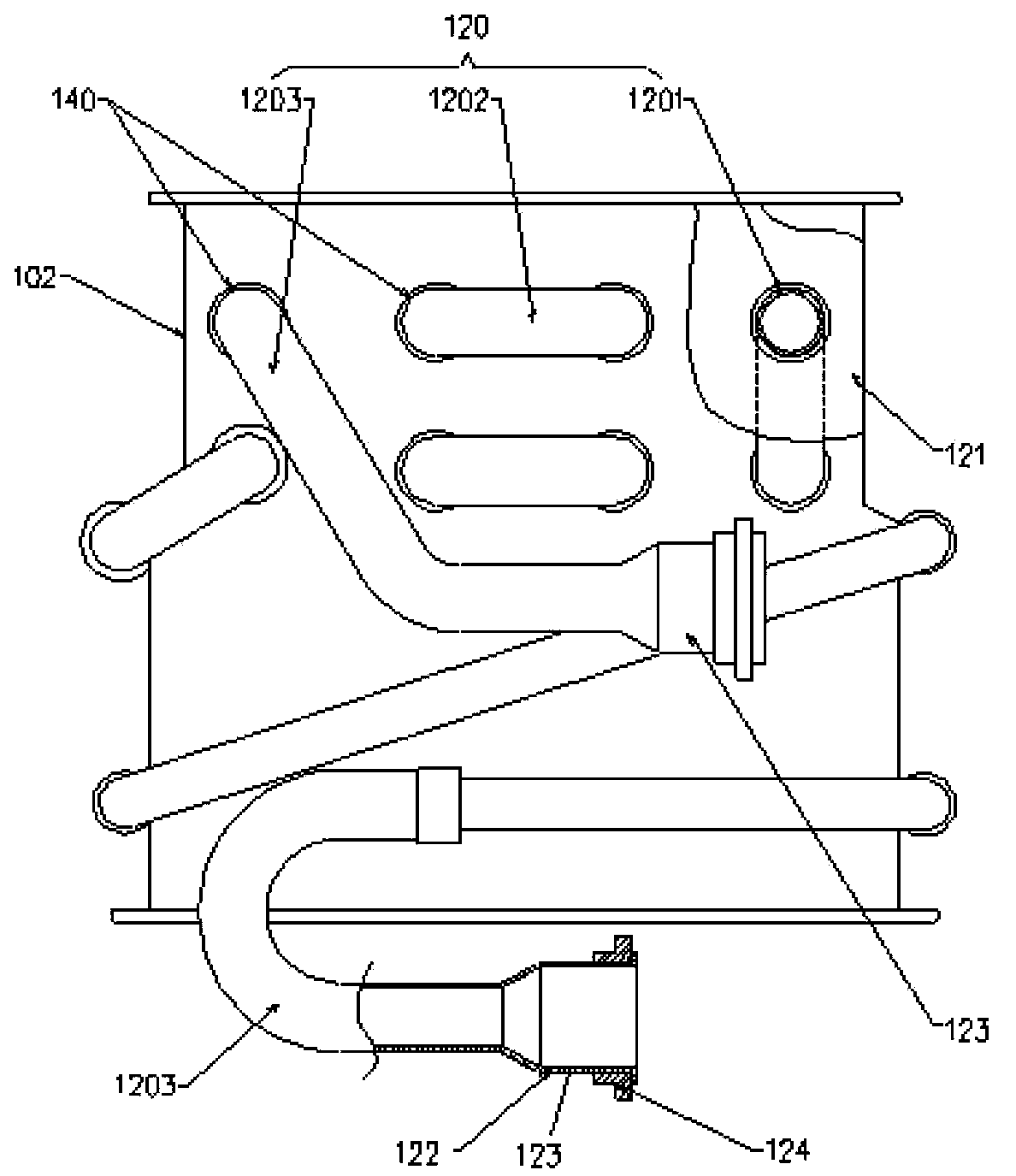

[0055] figure 1 It shows a schematic structural diagram of a water heater in the prior art. A plurality of plate-shaped heat-absorbing fins (121) are arranged side by side in the box (102), and the pipe (120) flowing with the heated fluid inside goes back and forth multiple times and runs through the box. Body and plate-shaped heat-absorbing fins (121), the pipe (120) is composed of three parts, namely the straight pipe part (1201), the U pipe part (1202) and the connecting pipe part (1203), and the straight pipe part is stored in the box Inside the body (102), the U pipe part is a U-shaped pipe connected to the adjacent straight pipe parts (1201)...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap