Electric steering engine electrical failure rapid detection circuit and method

An electric steering gear and detection circuit technology, applied in the detection field, can solve problems such as circuit and component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

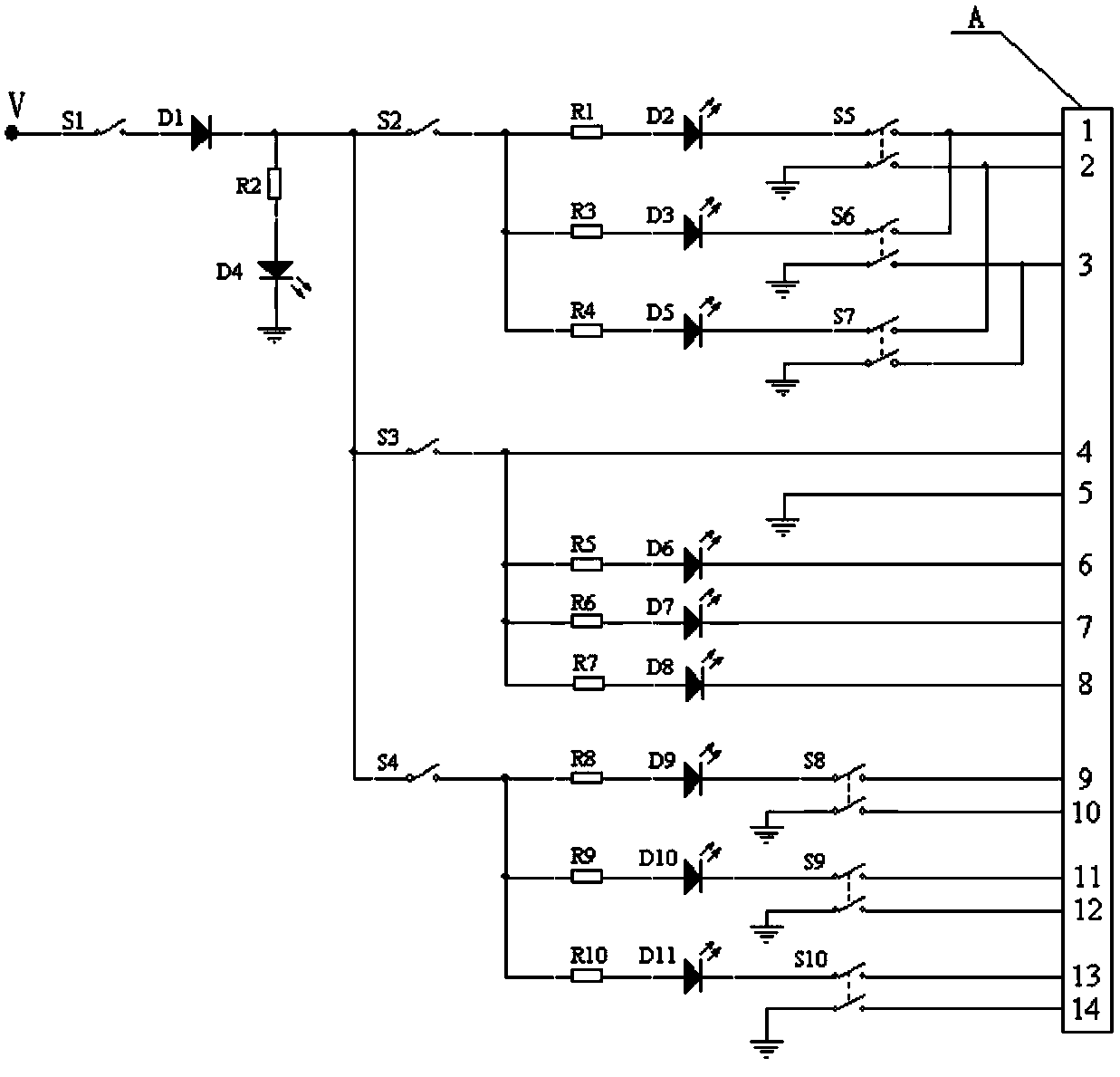

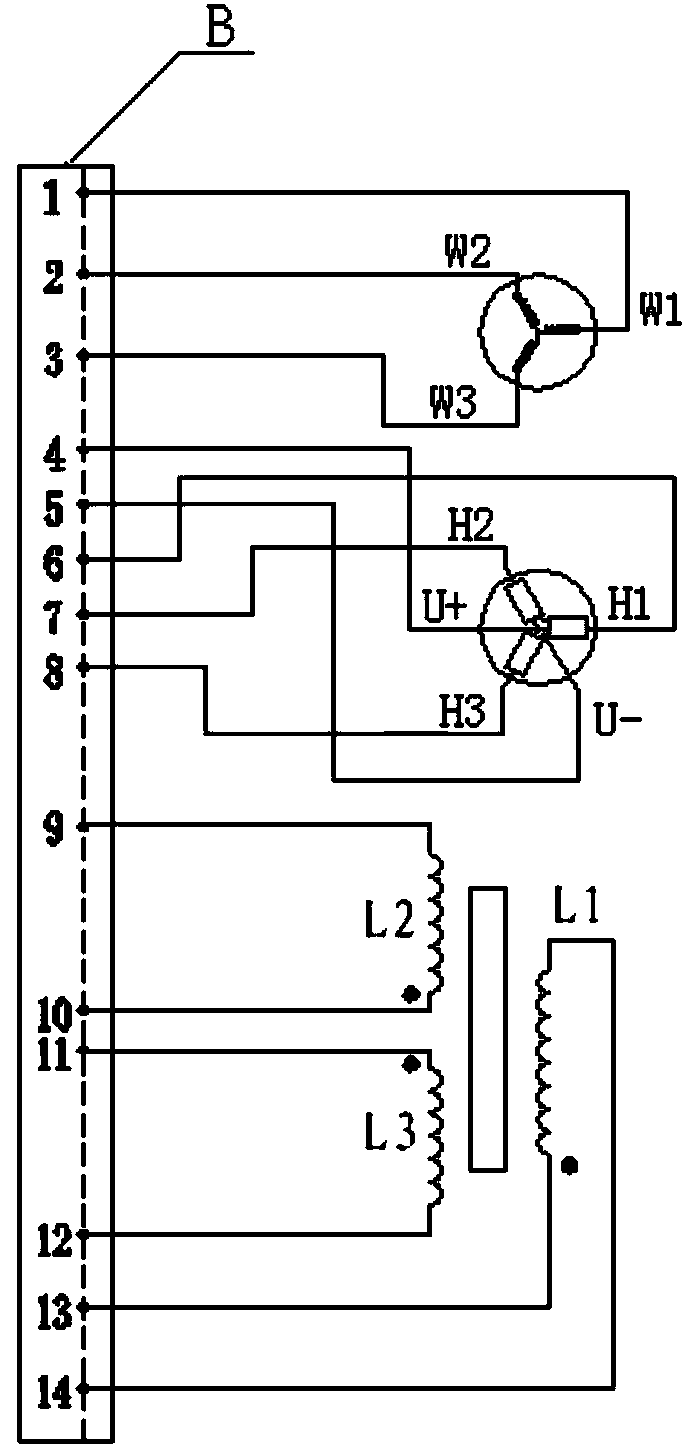

Embodiment 1

[0089] In Embodiment 1 of the present invention, the stator winding of the motor in the electric steering gear is detected, and the detection preparation is made according to the detection step 1, and then the first SPST switch S1 and the second SPST switch S2 are closed. Double-pole single-throw switch S5, the state of the first double-pole single-throw switch S5 and the first light-emitting diode D2 is recorded in the stator winding detection truth table, and its values are: S5 is 1, S6 is 0, S7 is 0, D2 is 0; when the second double-pole single-throw switch S6 is closed, the state of the first double-pole single-throw switch S5 and the first light-emitting diode D2 is recorded in the stator winding detection truth table, and its value is: S5 is 1, S6 is 0, S7 is 0, D2 is 0; then the first double-pole single-throw switch S5 is disconnected; the second double-pole single-throw switch S6 is closed, and the second double-pole single-throw switch S6 and the second light-emitting...

Embodiment 2

[0091] In Embodiment 2 of the present invention, the motor Hall commutation unit in the electric steering gear is detected, and the detection preparation is made according to the detection step 1,

[0092] Then close the third single-pole single-throw switch S3, continuously rotate the rotating shaft of the electric steering gear in one direction by hand, and observe the on-off status of the fifth light-emitting diode D6, the sixth light-emitting diode D7, and the seventh light-emitting diode D8; The fifth light-emitting diode D6 and the seventh light-emitting diode D8 are turned on and then turned off, and the sixth light-emitting diode D7 is always off, so it can be judged that the H2 phase of the brushless DC motor Hall commutation unit in the steering gear exists Fault; After completing the detection of the motor Hall commutation unit of the electric steering gear, disconnect the third single-pole single-throw switch S3;

Embodiment 3

[0094]In embodiment 3 of the present invention, the position sensor of the electric steering gear is detected, and the detection preparation is made according to the detection step 1, and then the fourth single-pole single-throw switch S4 is closed, the fourth double-pole single-throw switch S8 is closed, and the eighth light-emitting diode If it is on, it is judged that the secondary winding L2 of the position sensor is not faulty; when the fifth double-pole single-throw switch S9 is closed, the ninth light-emitting diode D10 is lit, and it is judged that the secondary winding L3 of the position sensor is faultless; when the sixth double-pole single-throw switch S10 is closed , the tenth light-emitting diode D11 does not light up, and it is determined that the secondary winding L2 of the position sensor is disconnected. After the position sensor detection of the electric steering gear is completed, the fourth SPST switch S4 is turned off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com