Substrate with interference type optical filter layer and displaying device with substrate

A technology for display devices and optical filters, applied in the direction of optical filters, optics, optical components, etc., can solve problems such as loss and achieve high light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

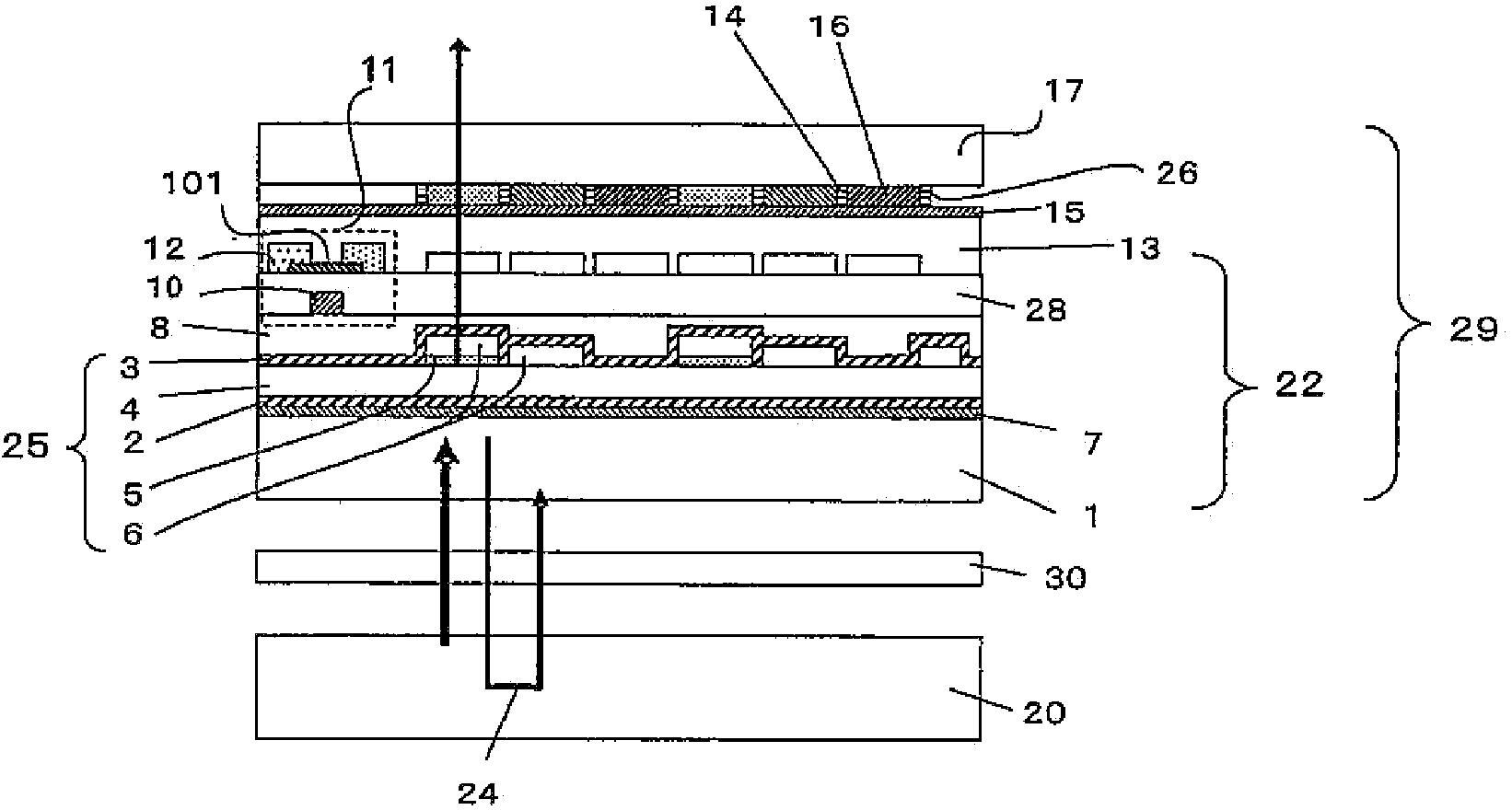

[0071] FIG. 7 shows a method of manufacturing a substrate with an interference filter layer according to the first embodiment.

[0072] As shown in FIG. 7( a ), a silicon oxide film of 100 nm was formed on a glass substrate 1 by CVD as an undercoat layer 7 . Next, 25 nm of Ag was deposited on the entire surface by vacuum evaporation to form the first reflective layer 2 . Next, a silicon oxide film was formed with a thickness of 100 nm by CVD to form the first spacer layer 4 , and a silicon nitride film was formed with a thickness of 25 nm by CVD to form the second spacer layer 5 . Next, the photosensitive resist layer 23 is patterned on the second spacer layer 5 , and the second spacer layer 5 is etched by chemical dry etching to remove the resist layer 23 .

[0073] When performing etching, the etching conditions of chemical dry etching are as follows: if the selectivity ratio of the silicon nitride film and the silicon oxide film is high enough, that is, the etching speed o...

Embodiment 2

[0084] The difference between Embodiment 2 and Embodiment 1 lies in that the patterns of the first space, the second space, and the third space constituting the optical filter layer are different. The same reference numerals are assigned to the same structures as those in Embodiment 1, and descriptions of the same structures are omitted.

[0085] FIG. 9 shows another example of the substrate with a filter layer and its manufacturing method related to the second embodiment.

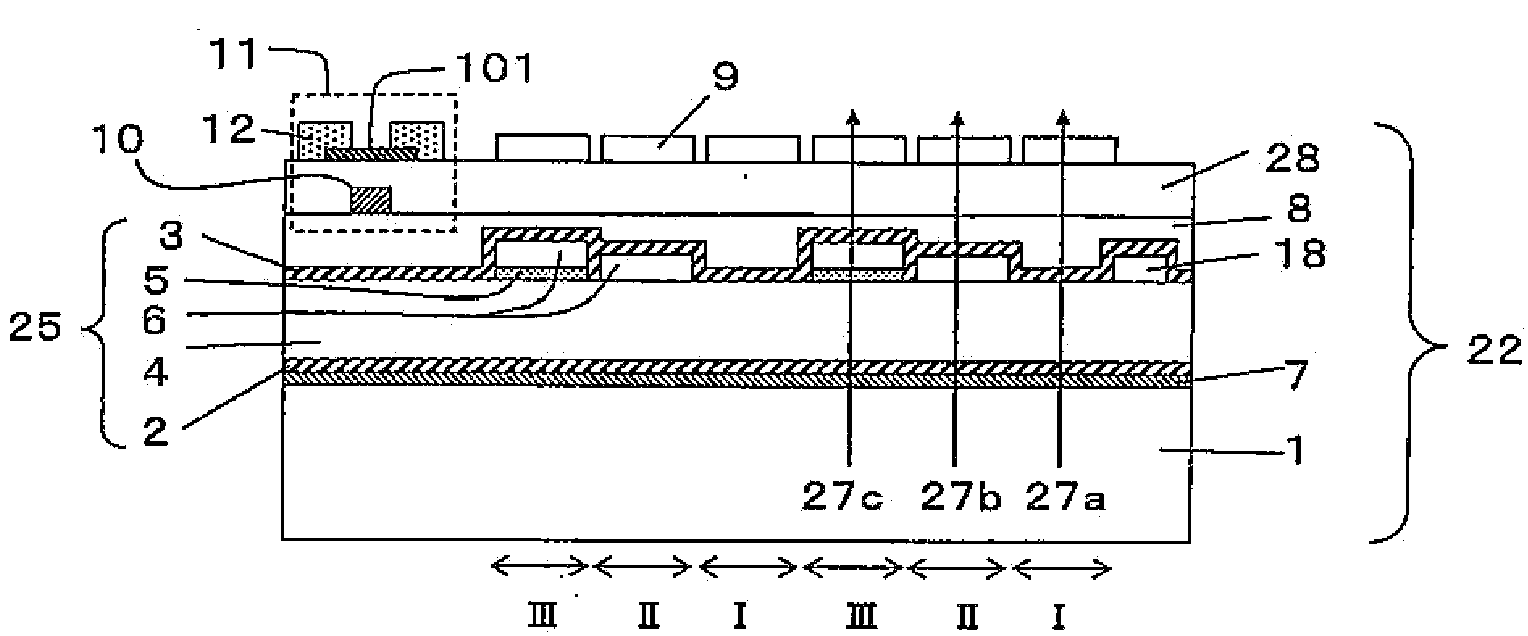

[0086] The manufactured substrate with a filter layer of Example 2 is shown in FIG. 9( c ), and the structure of the filter layer 25 is different from that of Example 1. That is, in the filter layer 25 of Example 2, the second spacer layer 5 is provided on a part of the first spacer layer 4 . In addition, the third spacer layer 6 is provided on a part of the region where the second spacer layer 5 is not provided on the first spacer layer 4 . Therefore, the filter layer 25 has three types: a region I havi...

Embodiment 3

[0093] In addition, it is also possible to use Figure 10 that kind of structure. That is, the second spacer layer 5 is provided at least two places on the first reflective layer 2 . The first spacer layer 4 is disposed on the second spacer layer 5 and the first reflective layer 2 . Furthermore, a third spacer layer 6 is provided on the first spacer layer 4 provided on one of the two second spacer layers 5 .

[0094] In addition, the third spacer layer 6 is also provided on a portion of the first spacer layer 4 where the second spacer layer 5 is not provided.

[0095] Thus, the filter layer 25 has the following four regions. That is, the filter layer 25 has a region I in which only the first spacer layer 4 is used as a transmissive layer, a region II in which the first spacer layer 4 is provided on the second spacer layer 5, and a region II in which the first spacer layer 4 is provided on the first spacer layer 4. Region III with three spacer layers 6 and region IV with se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap