A light-combining prism parallel micro-motion device for laser gyroscope light-combining assembly

A light-combining prism and laser gyro technology, applied in the direction of installation, optics, optical components, etc., to achieve the effect of no need for lubrication, simple and compact structure, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

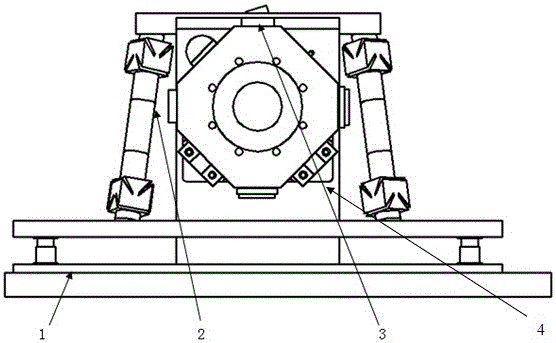

[0025] control figure 1 , 2 , 3, 4, 5, 6, 7, 8, the light-combining prism parallel micro-movement device used for laser gyro light-combining assembly, including an optical platform (1), a light-combining prism parallel micro-motion platform (2) and The optical element (3) to be assembled in the laser gyro optical combination assembly. The light-combining prism parallel micro-motion platform (2) and the optical element (3) to be assembled in the laser gyro light-combining assembly are placed in the middle of the optical platform (1), and the light-combining prism parallel micro-motion platform (2) is fixed on the optical platform (2) by screws. On the platform (1), the optical element (3) to be assembled in the laser gyro light combination assembly is connected to the optical platform (1) through an adapter plate (4); the light combination prism parallel micro-motion platform (2) has Four linear drive rods (20) drive the light-combining prism (7) in the optical element (3) to...

Embodiment 2

[0026] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

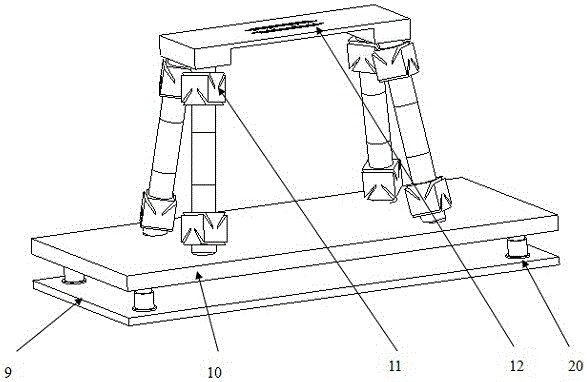

[0027] control figure 1 , 2 , 3. The light-combining prism parallel micro-motion platform (2) includes a bottom plate (9), a vertical lifting platform (10), four parallel branch chains (11) and a light-combining prism clamping mechanism (12) , the bottom plate (9) is fixed on the optical table (1), the vertical lifting platform (10) is fixed above the bottom plate (9), and one end of the parallel branch chain (11) is welded on the vertical lifting platform (10), The other end of the parallel branch chain (11) is welded to the light-combining prism clamping mechanism (12), and the four parallel branch chains (11) are symmetrically arranged between the vertical lifting platform (10) and the light-combining prism clamping mechanism (12) .

[0028] control figure 1 , 2 , 3, 4, the parallel branch chain (11) includes a first flexible Hooke hinge (13), a piezoe...

Embodiment 3

[0030] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

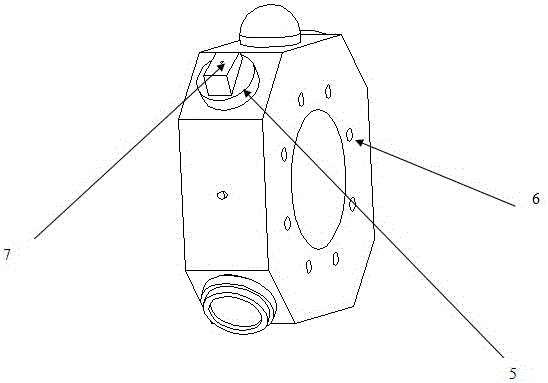

[0031] control figure 1 , 2 , the optical element (3) to be assembled in the laser gyro light combining assembly is composed of a resonant cavity (5), a plane mirror (6), and a light combining prism (7), and the plane mirror (6) is placed horizontally in the resonant cavity Body (5) laser beam exit port, light-combining prism (7) is placed horizontally on the plane mirror (6), in a free optical gel state. Through the adjustment of the mechanism, the operation of the light combining prism (7) is realized, so that the light spots of the clockwise and counterclockwise beams of light emitted overlap.

[0032] control Image 6 , the rotational movement state of the combined light prism (7) around the Z axis in space.

[0033]control Figure 7 , the translational motion state of the light-combining prism (7) along the X-axis in space.

[0034] control Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com