Method for the preparation of cellulose ethers with high solids process, product obtained and uses of the product

A cellulose and solid technology, applied in the field of cellulose ether, can solve the problems of huge investment and maintenance costs, complex and expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

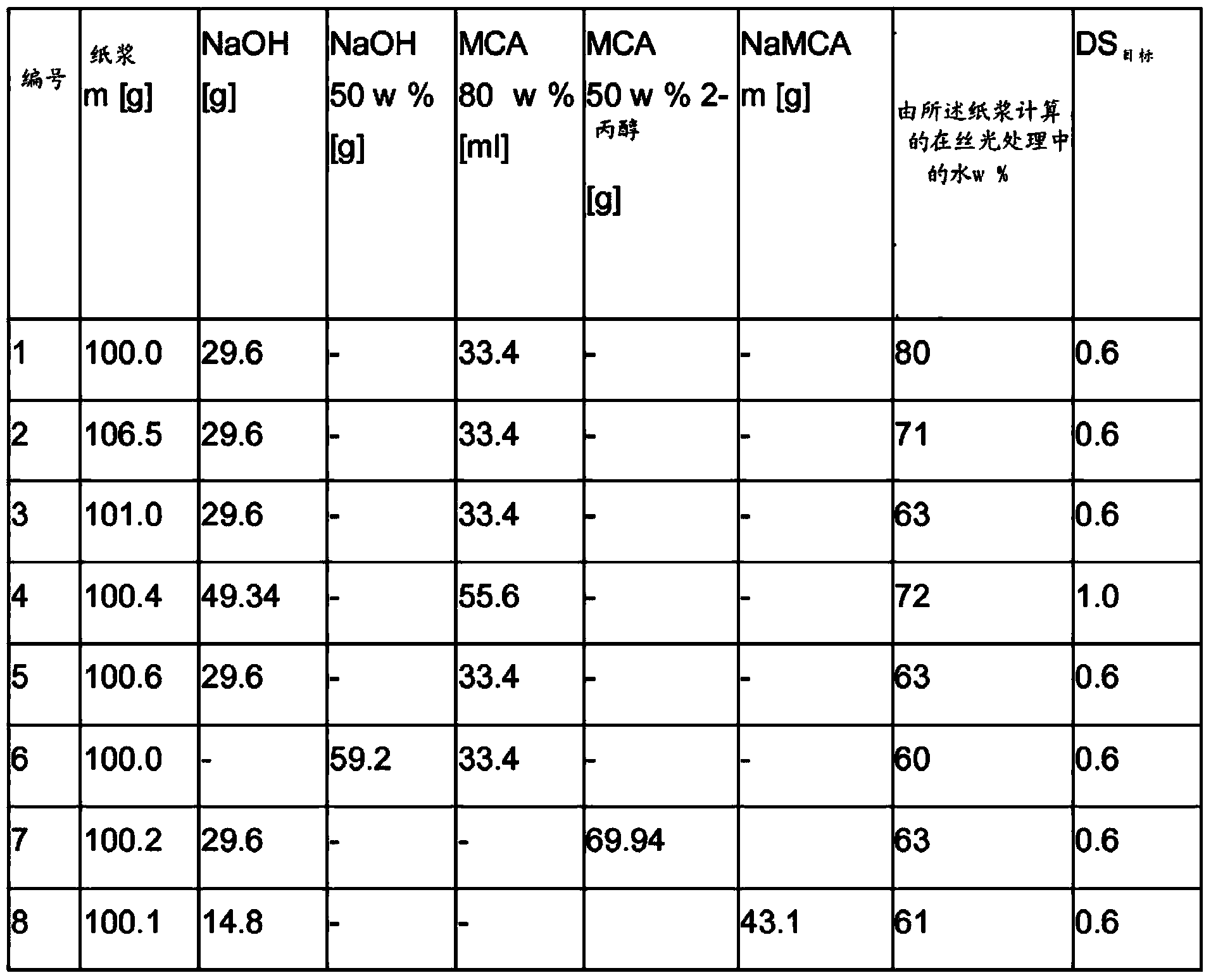

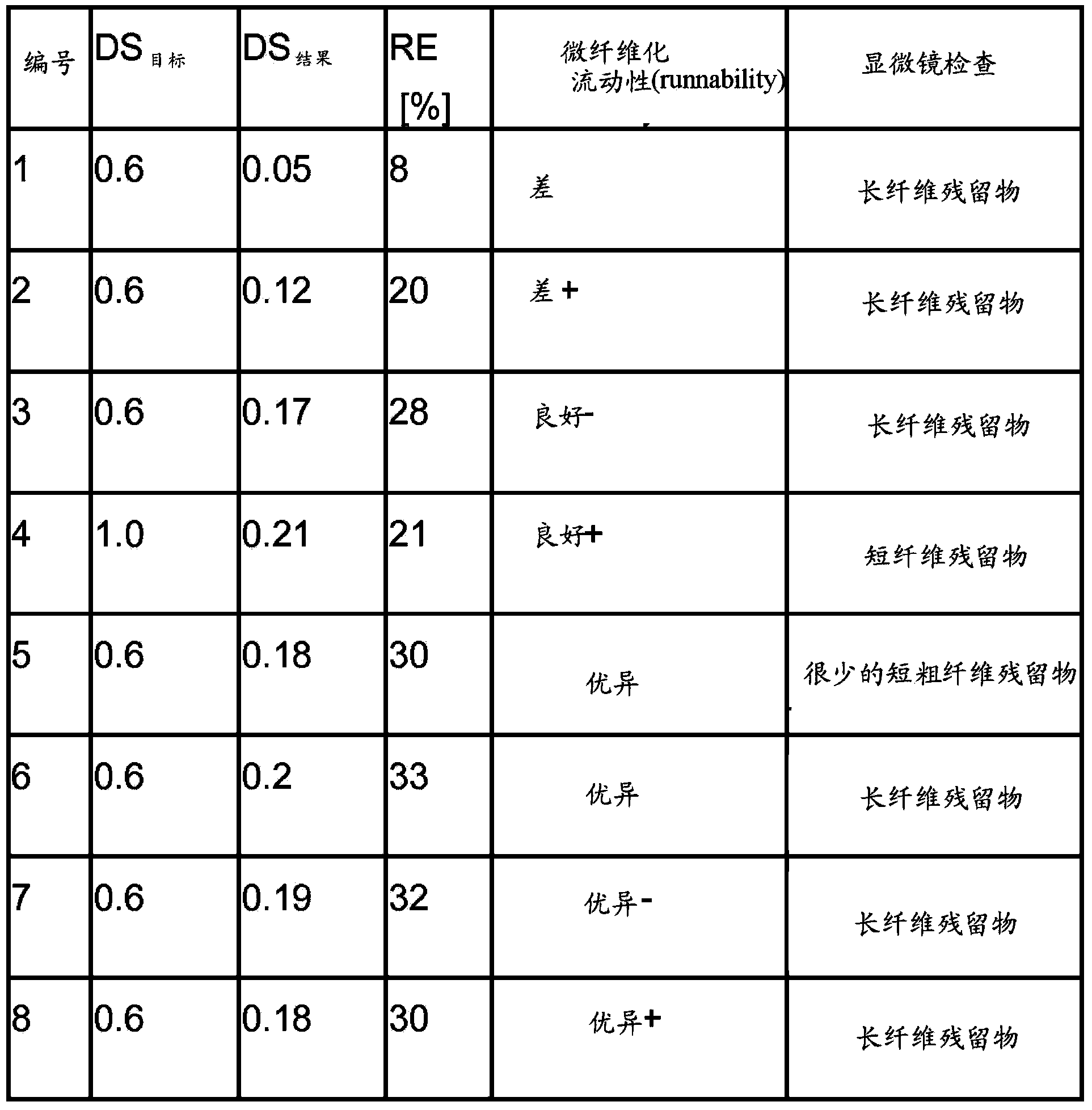

Embodiment 1

[0075] One hundred grams (calculated on dry matter) of undried pinewood pulp directly from the pulp mill was dewatered to give a solids content of 19.5% and a water content of 80.5%. A powder such as NaOH (29.6 g) was added to the pulp and the mixture was mixed mechanically with Kitchen aid for 30 minutes. The basified cellulose was allowed to stand overnight at 2°C. Mechanical mixing was continued and 33.4 ml of an 80w% monochloroacetic acid solution were added within 10 minutes with stirring. Mixing was continued for an additional 30 minutes, after which the material was placed in a sealed reactor in an oven at 105°C for 120 minutes. Allow the reactor to cool. The carboxymethylated cellulose fibers were suspended in 2 liters of water and the pH was adjusted to 7 with 35w% HCl. The material was filtered on a Bühner funnel and further washed three times with 3 liters of cold water. The wet material was further used to prepare MFC using Microfluidizer (Microfluidics Inc.). ...

Embodiment 6

[0080] Example 6 was prepared similarly to Example 1, however, during mixing with a dough mixer, 59.2 g of a 50w% NaOH solution were added dropwise to the mercerizing step rather than as a solid NaOH. After adding the NaOH solution, the experiment was continued analogously to Example 1.

Embodiment 7

[0081] Example 7 was prepared similarly to Example 1, but MCA was introduced dropwise into the mixture as a 50w% solution in 2-propanol instead of MCA as an 80w% aqueous solution. The amounts of chemicals are in Table 1. After adding the etherifying agent, the synthesis was continued analogously to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com