Agricultural integrally move type greenhouse

A mobile and greenhouse technology, applied in horticulture, greenhouse cultivation, climate change adaptation, etc., can solve the problems of land and capital waste, inability to move, time-consuming, etc., and achieve the effect of effective use and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

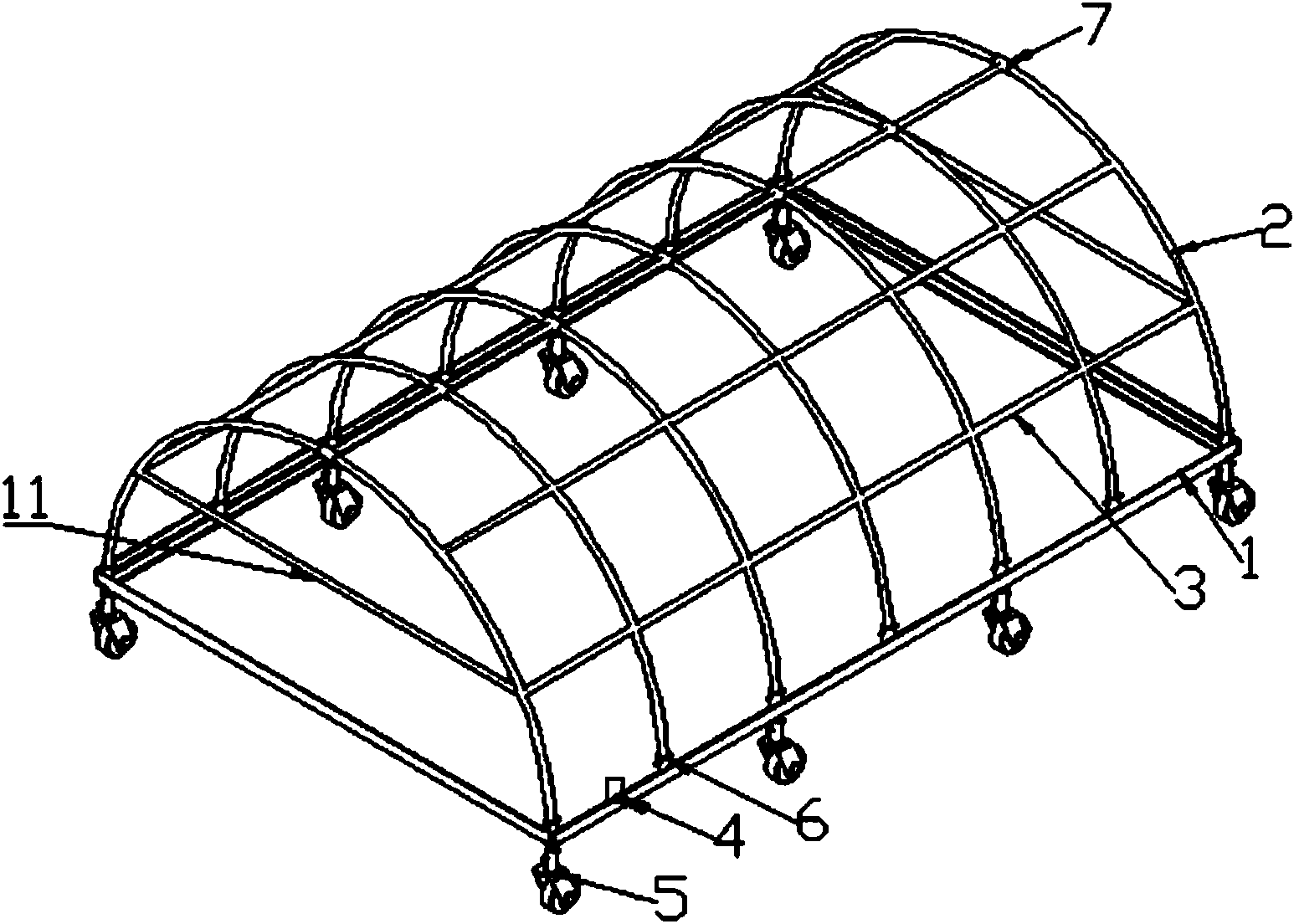

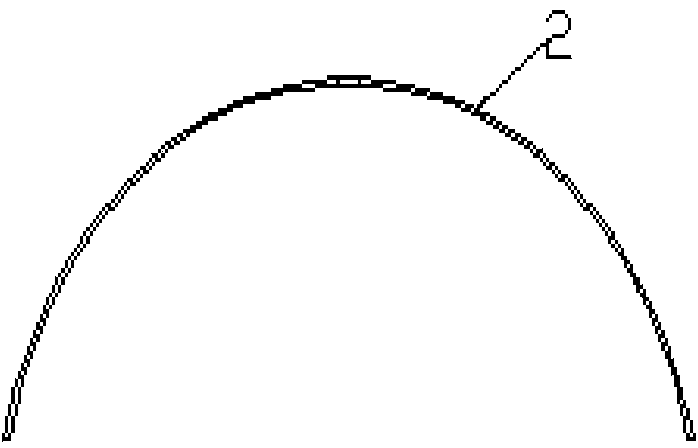

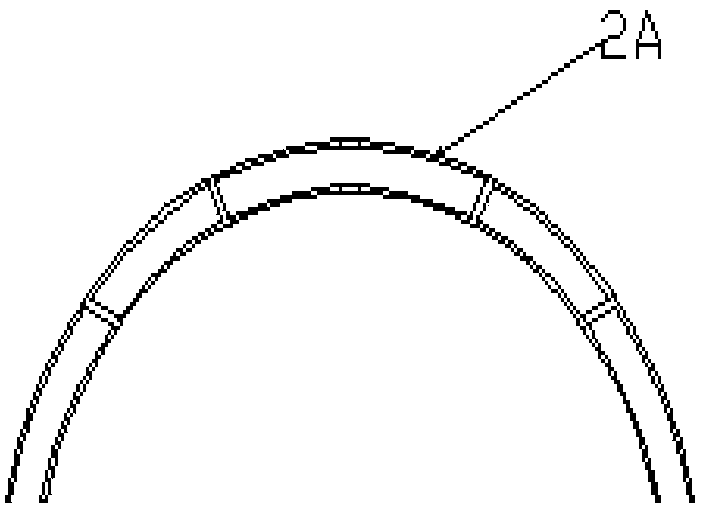

[0031] Such as figure 1 Shown, a kind of agricultural integrated mobile greenhouse of the present invention comprises sliding mechanism 5, film, chassis 1 (as image 3 shown), a plurality of arch beams arranged transversely on the underframe, and a plurality of tie rods 3 longitudinally connected between the arch beams. Wherein, the film is covered on the arch beam 2 and the tie rod 3, and the sliding mechanism 5 is installed under the chassis 1. The sliding mechanism 5 of this embodiment is a universal wheel, and the sliding mechanism 5 may also be a wheel.

[0032] Wherein, the greenhouse of the present embodiment also includes a door crossbar 11, which is installed on the first arch beam or the last arch beam among the plurality of arch beams; the door cross bar 11 passes through the door card 8 (As shown in Figure 4(a)) is connected with the arch beam.

[0033] Wherein, the arch beam is connected through the one-way connecting sleeve 6 arranged on the chassis 1 . The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com