High frequency pulse method for vacuum membrane distillation regeneration

A technology of vacuum membrane distillation and high-frequency pulse, which is applied in the direction of separation methods, chemical instruments and methods, and total evaporation, etc., to achieve the effects of increasing service life, improving separation efficiency, and increasing driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

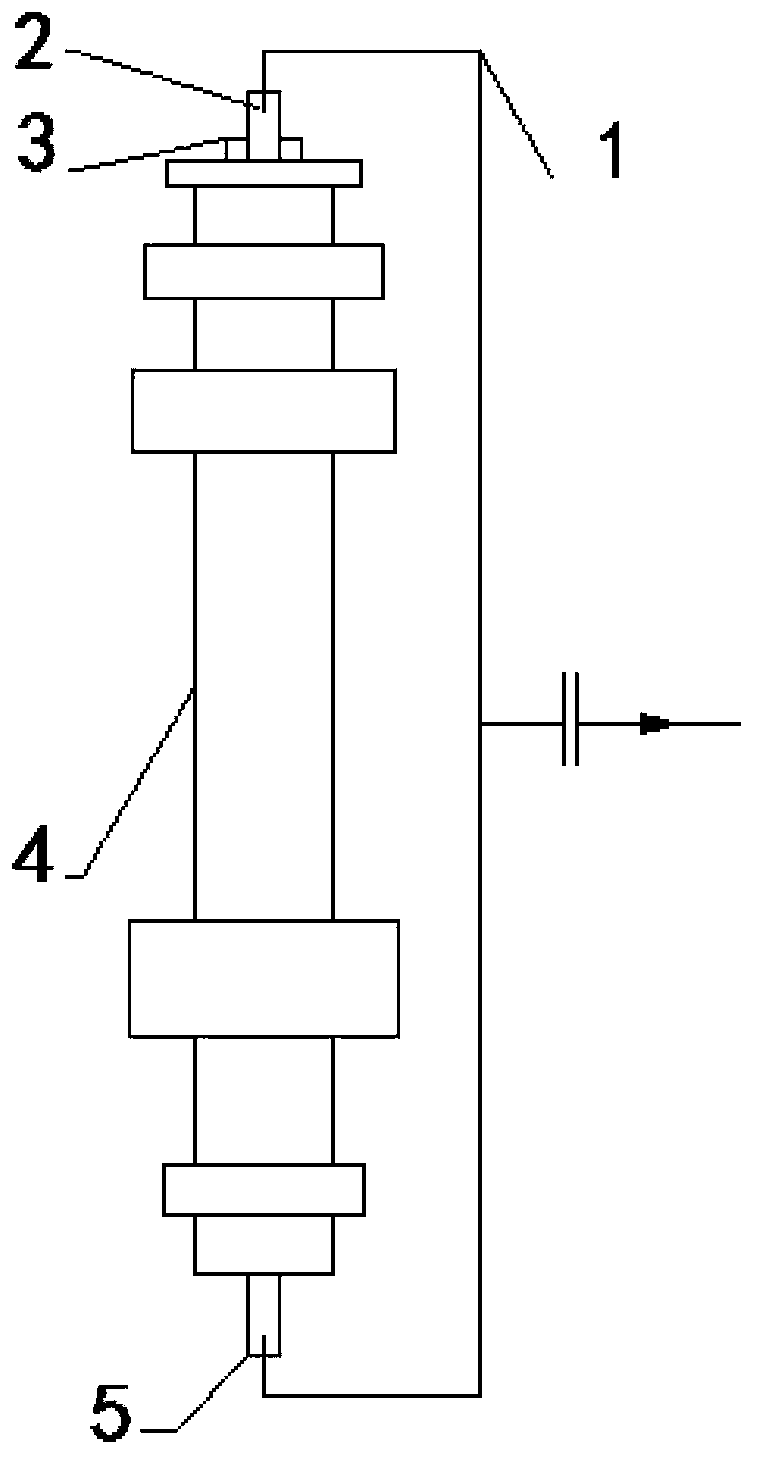

[0023] Embodiment 1: as figure 1 Shown, a kind of high-frequency pulse is used for vacuum membrane distillation regeneration method, contains following steps;

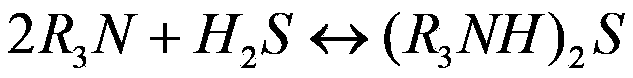

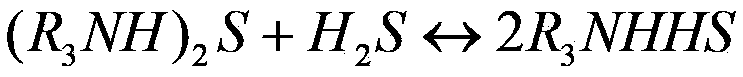

[0024] After the power supply is connected to 220V AC with a frequency of 50Hz, the output voltage is 1KV ~ 10KV, and the frequency is 1.31KHz ~ 8KHz high-frequency pulse signal after conversion by the step-up transformer. The high-frequency pulse signal is inserted into the solution inlet of the membrane module. The outlet of the solution is connected to the high-frequency pulse electrode at the inlet through a wire. The high-frequency pulse causes the pressure in the solution of the device to change rapidly, and the gas in the solution and a large number of bubbles generated by the pressure change occur frequently in a very short period of time. The eruption and collapse of bubbles, the eruption and collapse of bubbles will generate strong shock waves, which will cause the local temperature and pressure in the soluti...

Embodiment 2

[0035] Embodiment 2: as figure 1 Shown, a kind of high-frequency pulse is used for vacuum membrane distillation regeneration method, contains following steps;

[0036] The MDEA-rich solution that needs to be regenerated is heated to the experimental temperature by the heating tank and delivered to the membrane module. The AC power supply device outputs a high-frequency pulse signal after being converted by a step-up transformer. The pulse signal causes the pressure in the solution to change sharply, and the gas in the solution The large number of bubbles produced by itself due to pressure changes will frequently erupt and collapse in a very short period of time. The eruption and collapse of the bubbles will generate a strong shock wave, which will cause the local temperature and pressure in the solution to rise sharply. The local temperature and Changes in pressure lead to intensified solution oscillations, increased membrane permeability, and full contact between the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com